Selective catalytic reduction (SCR) denitration system and method based on constraint predictive control

A technology of predictive control and SCR reactor, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc. It can solve problems such as blockage, difficulty in ensuring the economy and safety of power plants, and difficulty in obtaining satisfactory control effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

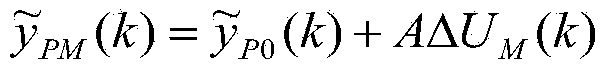

[0130] An optimal control method for an SCR denitrification system based on constraint predictive control, the specific steps are as follows:

[0131] 1) Under steady-state conditions, taking the valve opening of ammonia injection valve 4 as input, the model W of ammonia injection valve 4 is obtained through step response test 01 (s), SCR reactor 2 model W 02 (s), namely:

[0132] W 01 ( s ) = 1.3507 ( 2 s + 1 ) ( ( kg / h ) / % )

[0133] W 02 ( s ) = - 1.9046 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com