Method for making high-frequency aluminium-based circuit board

A production method and circuit board technology, applied in the direction of circuit substrate materials, printed circuit manufacturing, printed circuits, etc., can solve the problem of affecting the signal transmission performance of client products, not suitable for high-frequency aluminum-based Teflon materials, board edges and apertures Deformation and other problems, to improve product quality and work efficiency, smooth milling edge, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

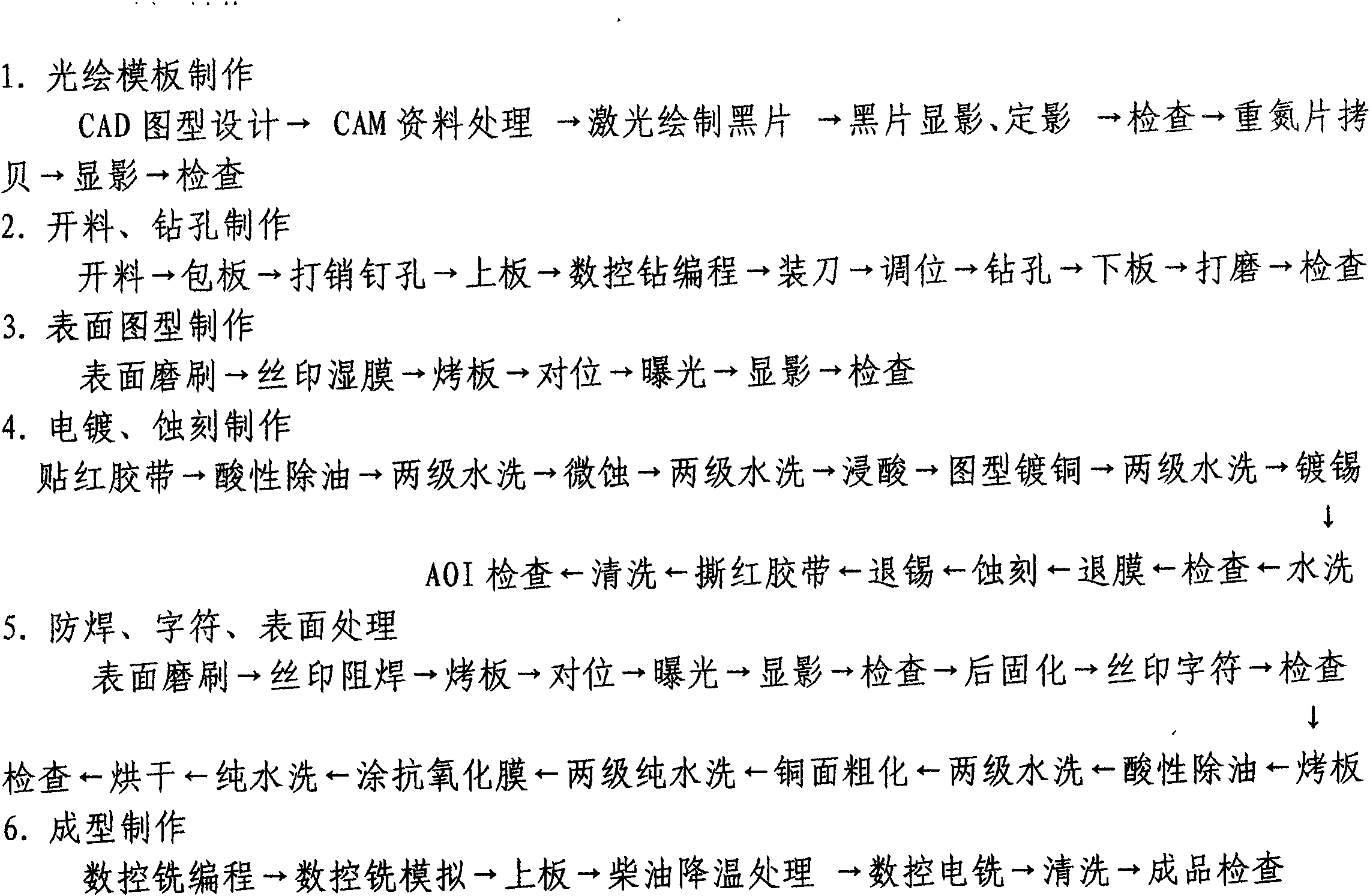

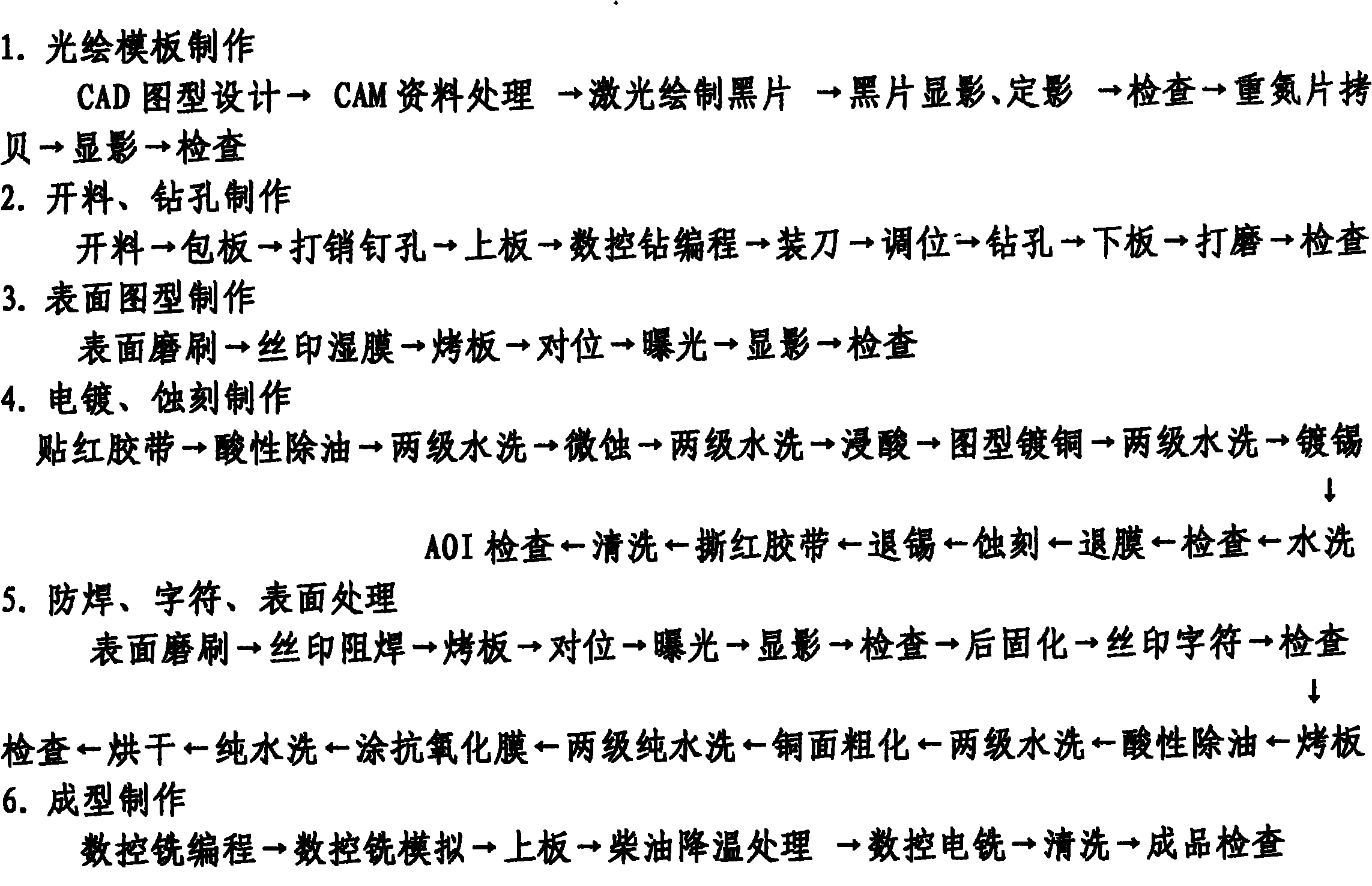

[0008] in figure 1 Among them, the present invention is a method for manufacturing a high-frequency aluminum-based circuit board, which includes the following steps: Step 1, light-painting template production: first, the template is graphically designed and the engineering file is processed in accordance with the production process parameters. The document is imposition, the black film is produced by a high-precision laser light plotter with a resolution of 20240dpi, the light-drawn film is washed, developed, fixed, washed, and air-dried, and then the drawn film is processed with a 200x magnifying glass Check, and finally use the 3KW exposure machine to copy the diazo film with the checked negative as the mother, and check the copied diazo film. Step two, the production of cutting and drilling: first use an electric shearing machine to open the high-frequency aluminum-based copper clad laminate required for production according to the size requirements, and then clad the board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com