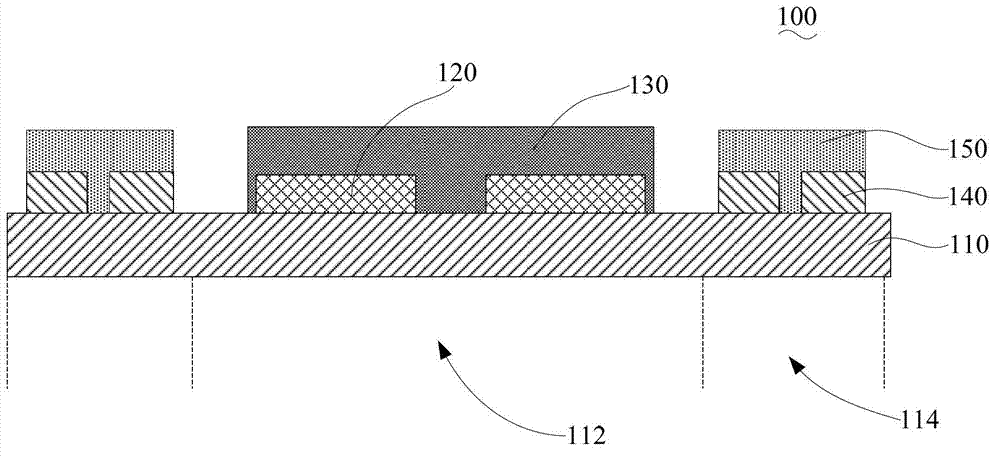

Touch input sheet and production method thereof

A touch input and production method technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc. It can achieve the effect of realizing mass production operation, improving adhesion and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

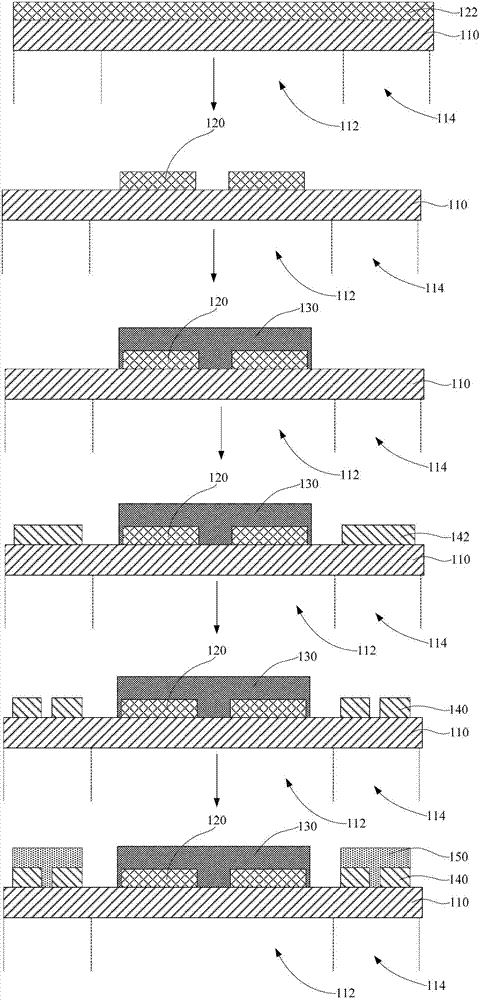

Embodiment 1

[0054] The transparent substrate uses a colorless and transparent ethylene terephthalate (PET) plastic film with a thickness of 50-125 μm, and forms ITO with a thickness of 10-30 nm as a conductive layer on its surface by sputtering. Aging treatment is carried out on the transparent substrate including the conductive layer by a high temperature of 140° C. to ensure that the stretch rate of the transparent substrate is within a normal range. Then, the conductive layer is processed by fully automatic printing to form the required conductive pattern in the visible area of the transparent substrate. The specific process is: use screen printing to print the preset conductive pattern area on the conductive layer The acid-resistant polyester is cured by ultraviolet light, and the polyester is cured by ultraviolet light; the conductive layer is etched with HCl solution, and the conductive layer in the visible area with the area other than the preset conductive pattern is etched away,...

Embodiment 2

[0057] The transparent substrate uses a colorless and transparent polybutylene terephthalate (PBT) plastic film with a thickness of 50-125 μm, and forms ITO with a thickness of 10-30 nm as a conductive layer on its surface by sputtering. Aging treatment is carried out on the transparent substrate including the conductive layer by a high temperature of 140° C. to ensure that the stretch rate of the transparent substrate is within a normal range. Then, the required circuit pattern is formed in the visible area through the yellow light process. The specific process is: coating the negative photoresist on the entire surface of the conductive layer, and exposing the negative photoresist to the preset conductive pattern area by exposure. for curing; then use K 2 CO 3 Develop the negative photoresist with an organic solution to remove the uncured negative photoresist; use HNO 3 The solution etches the conductive layer, and etch away the conductive layer with areas other than the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com