Battery pole piece making and battery cell coiling integrated equipment

A battery pole piece and battery cell technology, which is applied in the field of battery pole piece production and battery cell rolling integrated equipment, can solve the problems of cross contamination of positive and negative pole pieces, affect work efficiency, increase the difficulty of deviation correction, etc., and achieve overall The effects of size reduction, labor intensity reduction and working time shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

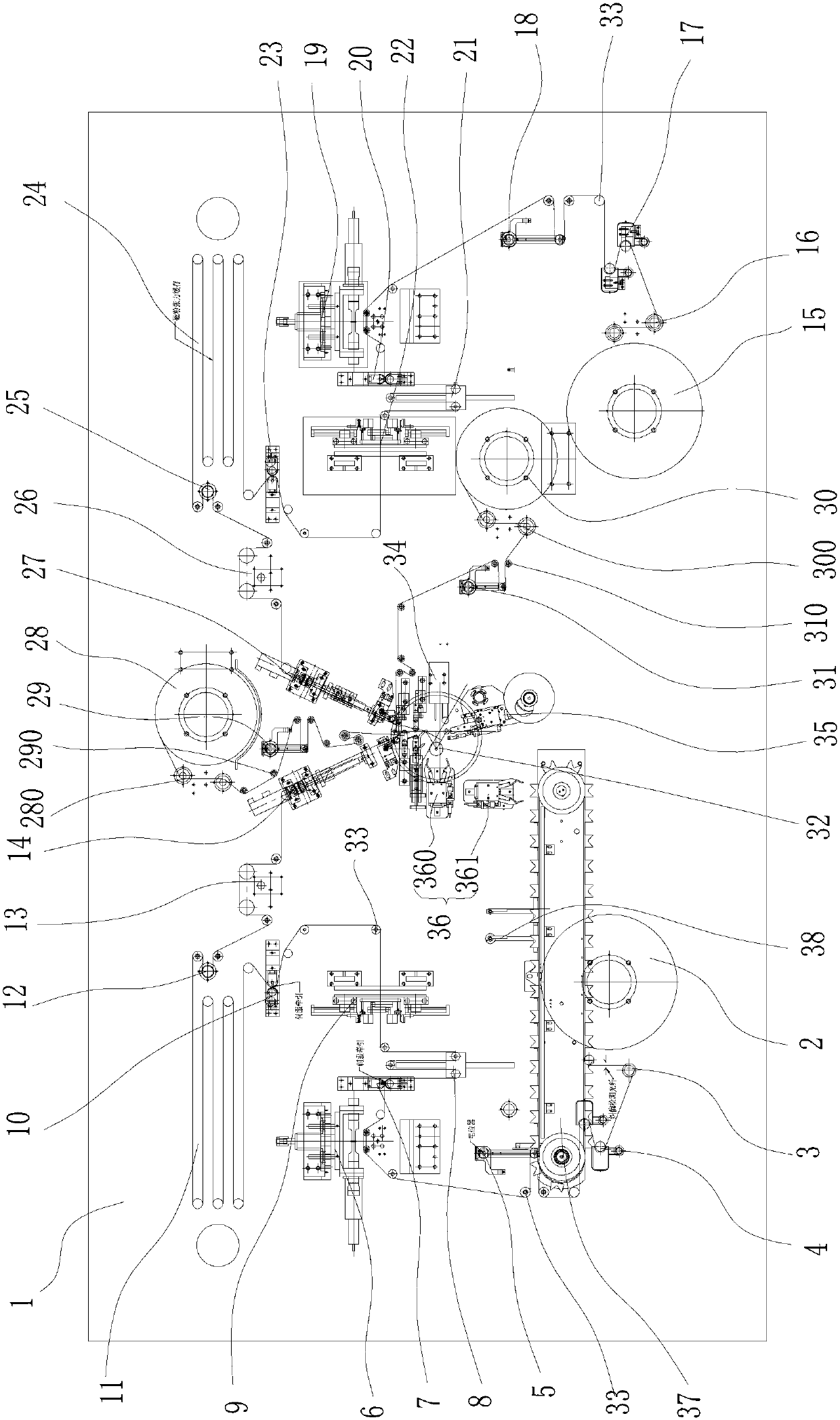

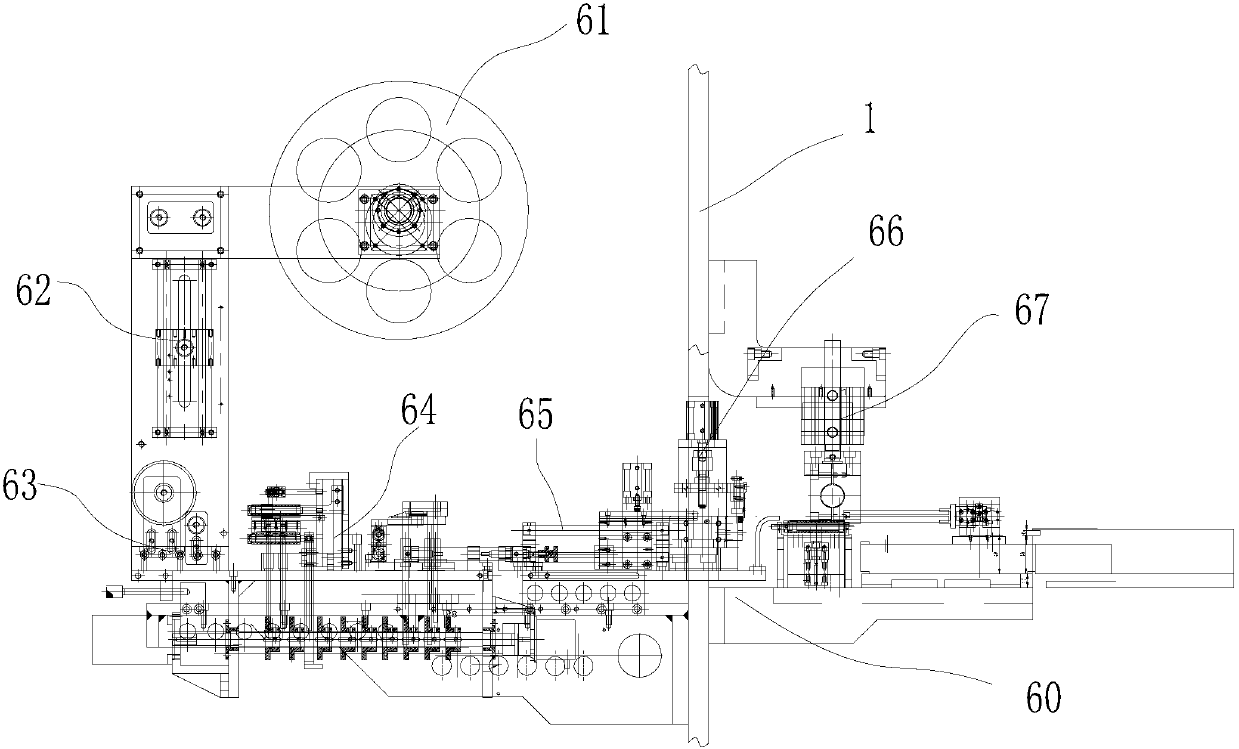

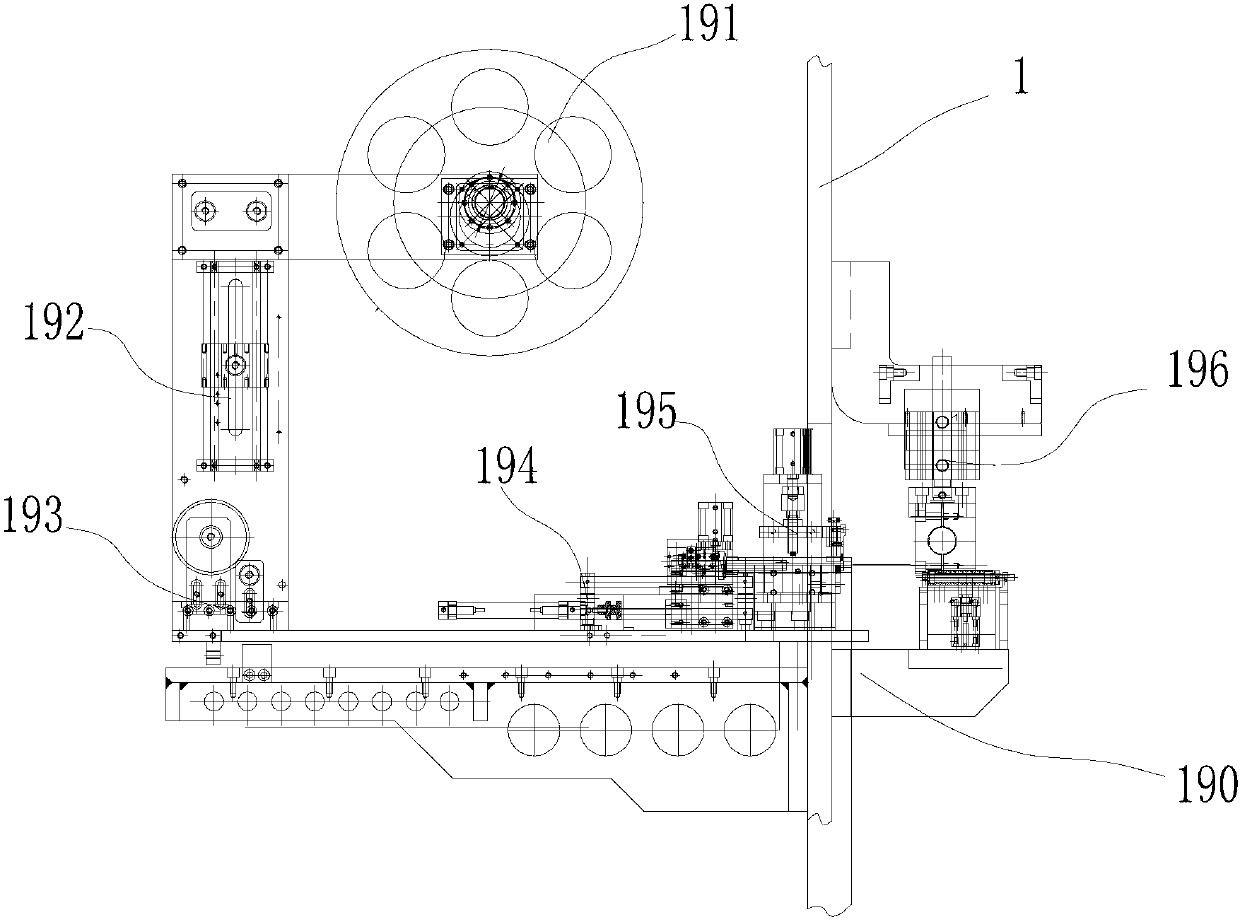

[0028] Integrated equipment for battery pole sheet production and cell rolling, such as figure 1 As shown, it includes a frame 1 and a control system, and a positive electrode sheet supply device 2, a positive electrode sheet deviation correction detection device 3, a positive electrode sheet dust removal mechanism 4, a positive electrode sheet tension mechanism 5, and a positive electrode sheet Ear welding device 6, positive electrode sheet first pulling device 7, positive electrode sheet buffering device 8, positive electrode sheet gluing device 9, positive electrode sheet second pulling device 10, positive electrode sheet tension buffer storage device 11, positive electrode sheet length measuring mechanism 12, Positive electrode sheet process correction mechanism 13, positive electrode sheet insertion mechanism 14; negative electrode sheet supply device 15, negative electrode sheet deviation correction detection device 16, negative electrode sheet dust removal mechanism 17, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com