Flash memory and manufacturing method therefor

A manufacturing method and memory technology, which are applied in the manufacturing of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of easy interference and unreliable performance of flash memory, and achieve the effect of avoiding mutual interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

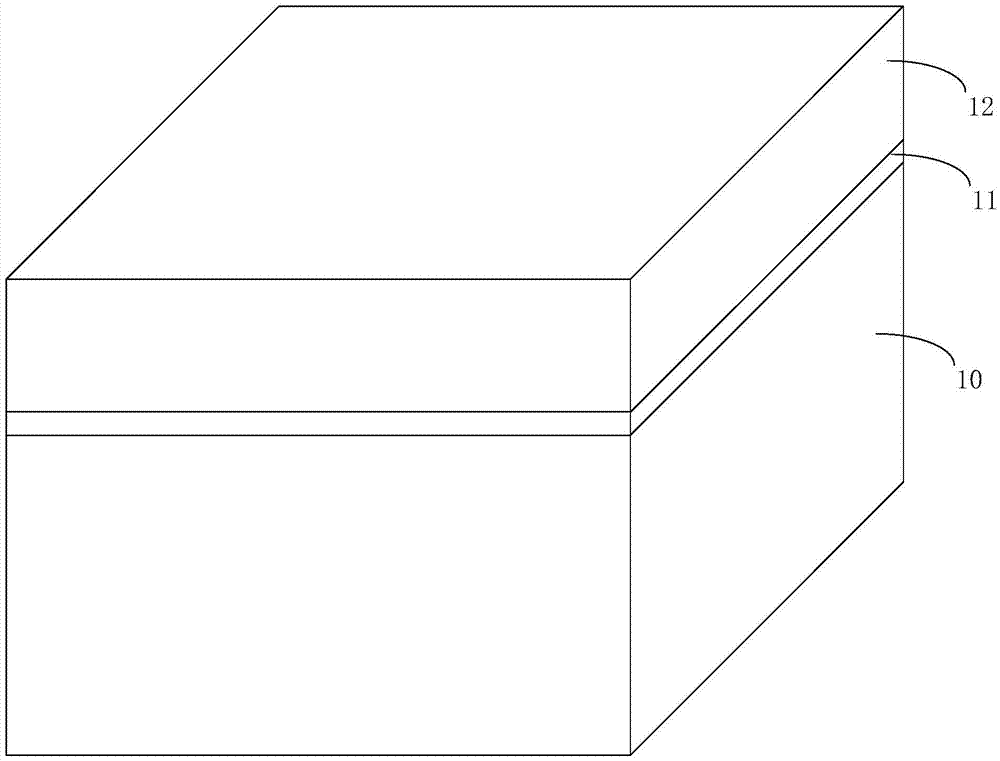

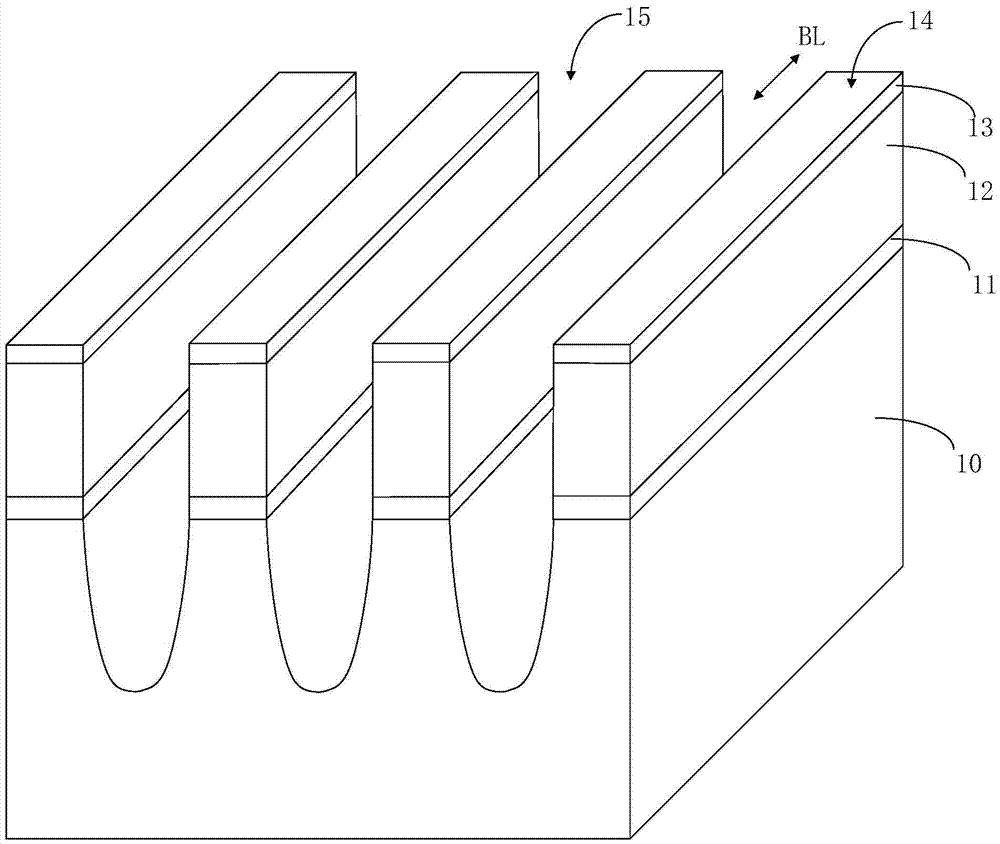

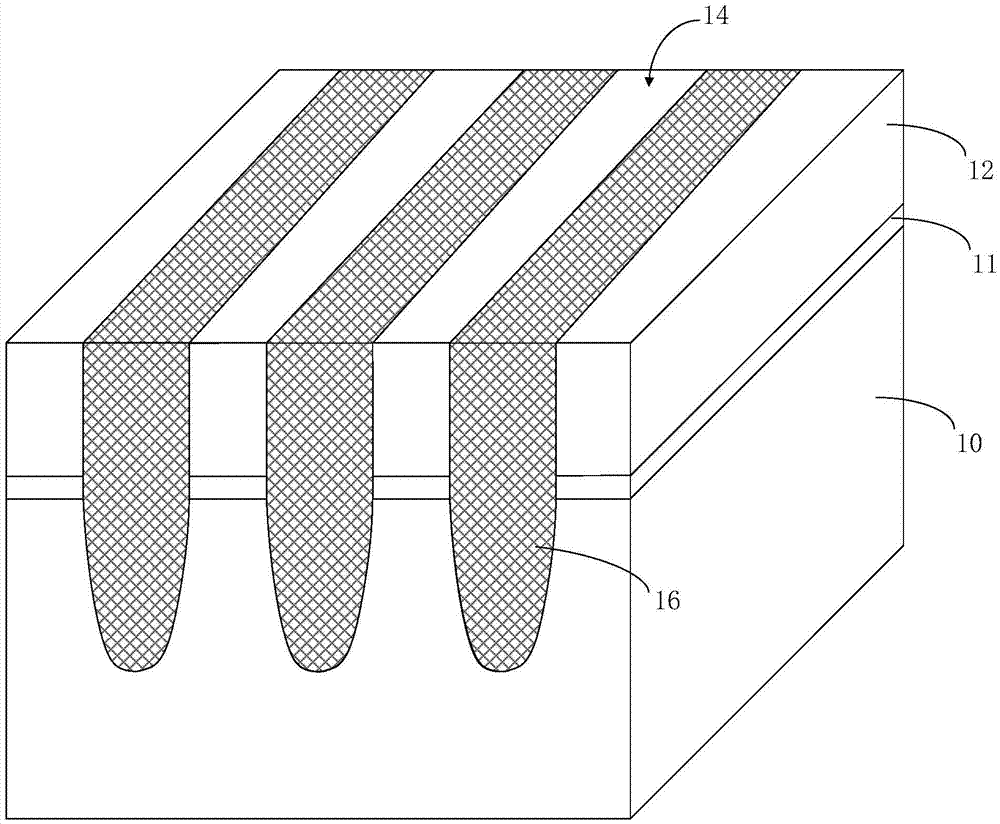

Embodiment Construction

[0035] As mentioned in the background technology, in the prior art, as the size decreases, the distance between adjacent flash memory cells becomes smaller, and interference between the two is prone to occur when reading, writing, and erasing, which will cause poor performance of the flash memory. reliable. After analysis, the inventor finds that the reason for this is: in order to electrically insulate the adjacent bit lines, isolation trenches are formed in the semiconductor substrate between the bit lines, and the trenches are filled with dielectric layers. In addition, for Electrically insulate each column of floating gate stack structures, and a dielectric layer is also filled between each column of floating gate stack structures. The material of the above two dielectric layers is generally silicon dioxide, and the dielectric constant is relatively large (generally about 4.2). , which causes the parasitic capacitance to be too large during the charging and discharging pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com