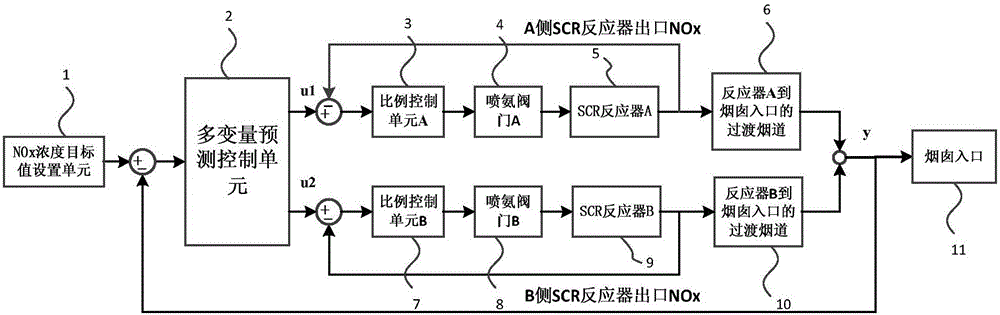

Multi-variable interval constrained estimation-based SCR denitration optimized control system and method

A technology of predictive control and optimal control, which is applied in the direction of controlling the mixing ratio of fluids at different temperatures, etc., can solve problems such as difficulty in obtaining satisfactory control effects, and difficulty in ensuring the economy and safety of power plants, so as to prolong life, reduce execution times, The effect of improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0063] The specific implementation method comprises the following steps:

[0064] 1) Under steady-state conditions, the model W of the ammonia injection valve A4 is obtained through the step response test 01 (s), model W of SCR reactor A5 02 (s), and the model W from reactor A to the chimney outlet 03 (s), namely:

[0065]

[0066]

[0067]

[0068] 2) Determine the parameter K of the proportional regulator Pa =-0.3,K Pb =-0.3, calculate the total model W(s) of the NOx concentration value of the multivariable predictive control unit 2 to the chimney inlet 11 input end=[W 1 (s), W 2 (s)] T :

[0069]

[0070]

[0071] The calculation method of the B-side model is the same as that of the A-side;

[0072] And get the step response coefficients of the total model W(s):

[0073] a 11 (1),a 11 (2),...,a 11 (N 1 )=[00...0.3811];

[0074] a 12 (1),a 12 (2),...,a 12 (N 2 )=[00...0.3811];

[0075] 3) Set the relevant parameters of the variable predictiv...

Embodiment 1

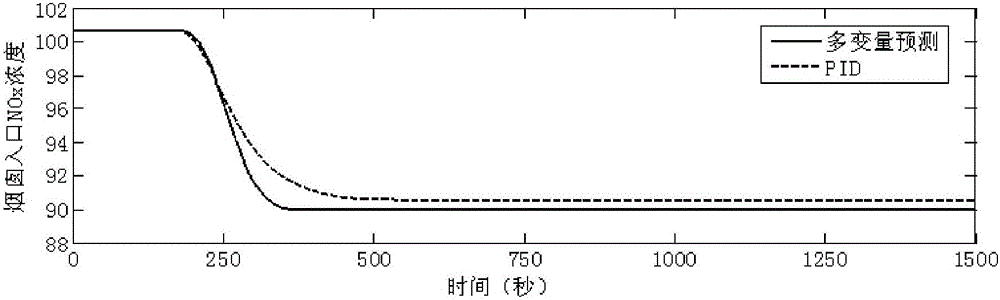

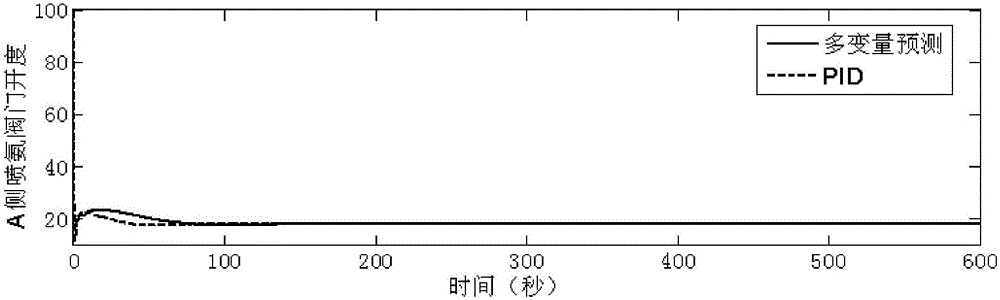

[0082] The comparison of the control effect of the SCR denitrification system based on the multivariable interval constraint predictive control of the present invention and the control effect of the PID controller obtained in Example 1 figure 2 , image 3 with Figure 4 As shown, the NOx control point of the present invention is at the chimney inlet, while the general PID control takes the NOx at the outlet of the SCR denitrification system as the controlled quantity, and the NOx concentration from the SCR outlet to the input end of the chimney inlet will change, so it can be seen from the figure To, the NOx of the chimney inlet input end under PID control does not reach the set value, and the multivariable interval constraint predictive control of the present invention can control the NOx of the chimney inlet input end in a given range; In contrast, the present invention can be in a shorter The control of the NOx concentration at the input end of the chimney inlet can be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com