Method of copper and iron alloy materials for novel motor rotors

A motor rotor, copper-iron alloy technology, applied in the direction of electrical components, magnetic field/electric field shielding, etc., can solve the problems of reducing the conductivity and permeability of the alloy, increasing the starting current of the motor rotor, and reducing the performance of the motor, so as to reduce segregation, The effect of increasing the electromagnetic shielding performance of the alloy and increasing the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

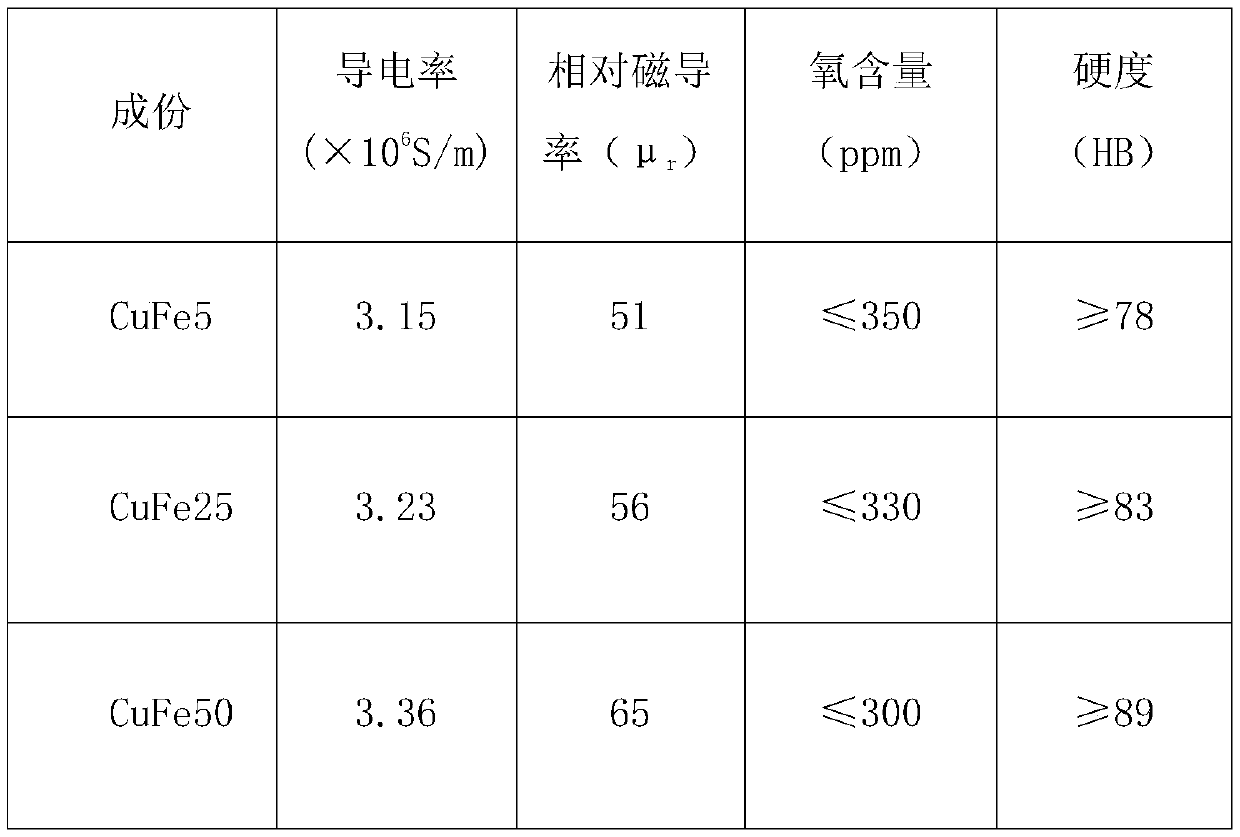

Embodiment 1

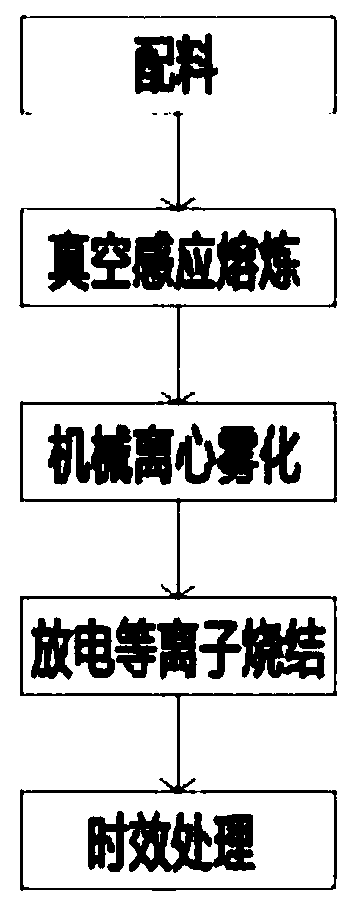

[0034] Such as figure 1 Shown, a kind of method for the copper-iron alloy material of novel motor rotor mainly comprises the following steps:

[0035] (1) Ingredients

[0036]The chemical composition and weight percentage of Cu-Fe alloy are: 93% copper, 0.95% silicon, 0.8% manganese, 0.07% phosphorus, 0.04% silver, 0.02% sulfur, 0.02% aluminum, 0.1% carbon, 5% iron, of which , Cu uses electrolytic copper plate, iron uses industrial pure iron, silicon uses ferrosilicon, and manganese uses ferromanganese;

[0037] (2) Vacuum induction melting

[0038] Put the electrolytic copper plate with the above weight percentage into the vacuum induction furnace, vacuumize, after the electrolytic copper plate is melted, add ferromanganese into the vacuum induction furnace for deoxidation, then add industrial pure iron and ferrosilicon respectively into the vacuum induction furnace, heat Raise the temperature to 1500°C for smelting, then add rare earths La and Ce and perform electromagnet...

Embodiment 2

[0046] Such as figure 1 Shown, a kind of method for the copper-iron alloy material of novel motor rotor mainly comprises the following steps:

[0047] (1) Ingredients

[0048] The chemical composition and weight percentage of Cu-Fe alloy are: 64% copper, 0.37% silicon, 0.5% manganese, 0.03% phosphorus, 0.02% silver, 0.015% sulfur, 0.015% aluminum, 0.05% carbon, 35% iron, of which , Cu uses electrolytic copper plate, iron uses industrial pure iron, silicon uses ferrosilicon, and manganese uses ferromanganese;

[0049] (2) Vacuum induction melting

[0050] Put the electrolytic copper plate with the above weight percentage into the vacuum induction furnace, vacuumize, after the electrolytic copper plate is melted, add ferromanganese into the vacuum induction furnace for deoxidation, then add industrial pure iron and ferrosilicon respectively into the vacuum induction furnace, heat Raise the temperature to 1600°C for smelting, then add rare earths La and Ce and carry out electr...

Embodiment 3

[0058] Such as figure 1 Shown, a kind of method for the copper-iron alloy material of novel motor rotor mainly comprises the following steps:

[0059] (1) Ingredients

[0060] The chemical composition and weight percentage of Cu-Fe alloy are: 49% copper, 0.31% silicon, 0.5% manganese, 0.03% phosphorus, 0.02% silver, 0.02% sulfur, 0.02% aluminum, 0.1% carbon, 50% iron, of which , Cu uses electrolytic copper plate, iron uses industrial pure iron, silicon uses ferrosilicon, and manganese uses ferromanganese;

[0061] (2) Vacuum induction melting

[0062] Put the electrolytic copper plate with the above weight percentage into the vacuum induction furnace, vacuumize, after the electrolytic copper plate is melted, add ferromanganese into the vacuum induction furnace for deoxidation, then add industrial pure iron and ferrosilicon respectively into the vacuum induction furnace, heat Raise the temperature to 1800°C for smelting, then add rare earths La and Ce and carry out electroma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com