A jig for making graphene suspension film into capacitor

A technology of graphene and capacitors, which is applied to parts of fixed capacitors, capacitors, fixed capacitors, etc., can solve the problems of affecting charge output, short circuit of two plates, and small capacitance value, so as to increase the dielectric constant and reduce the impact degree, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

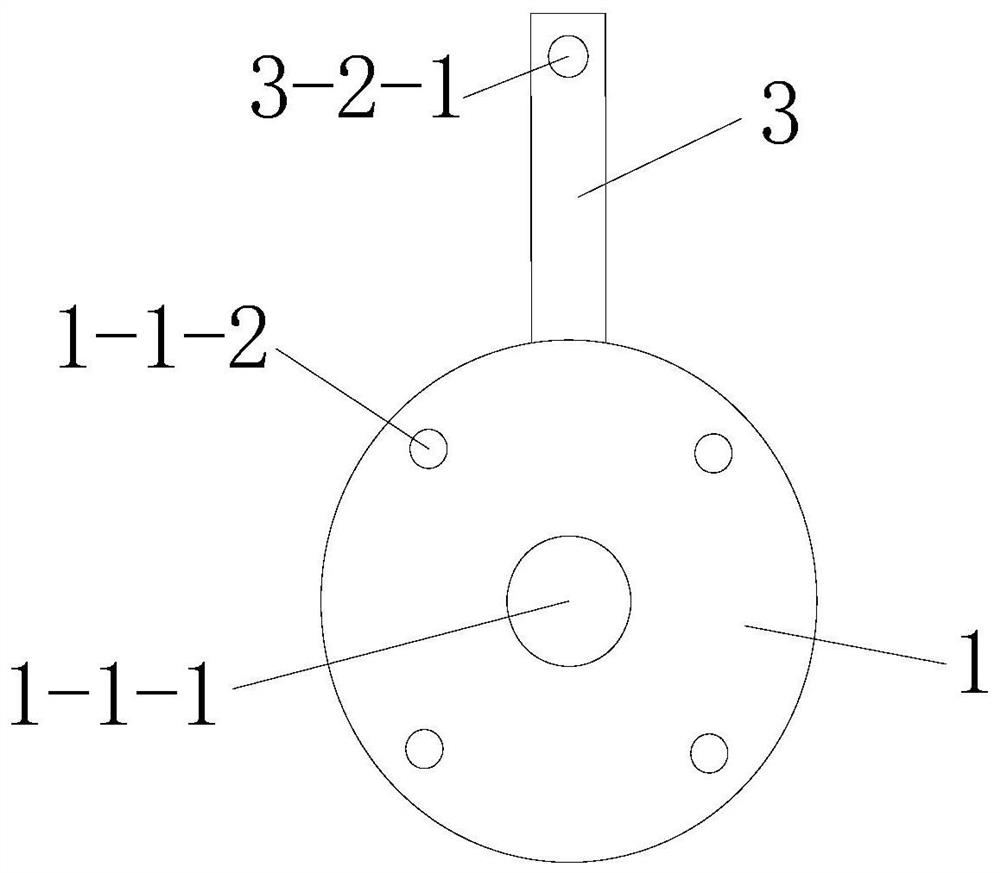

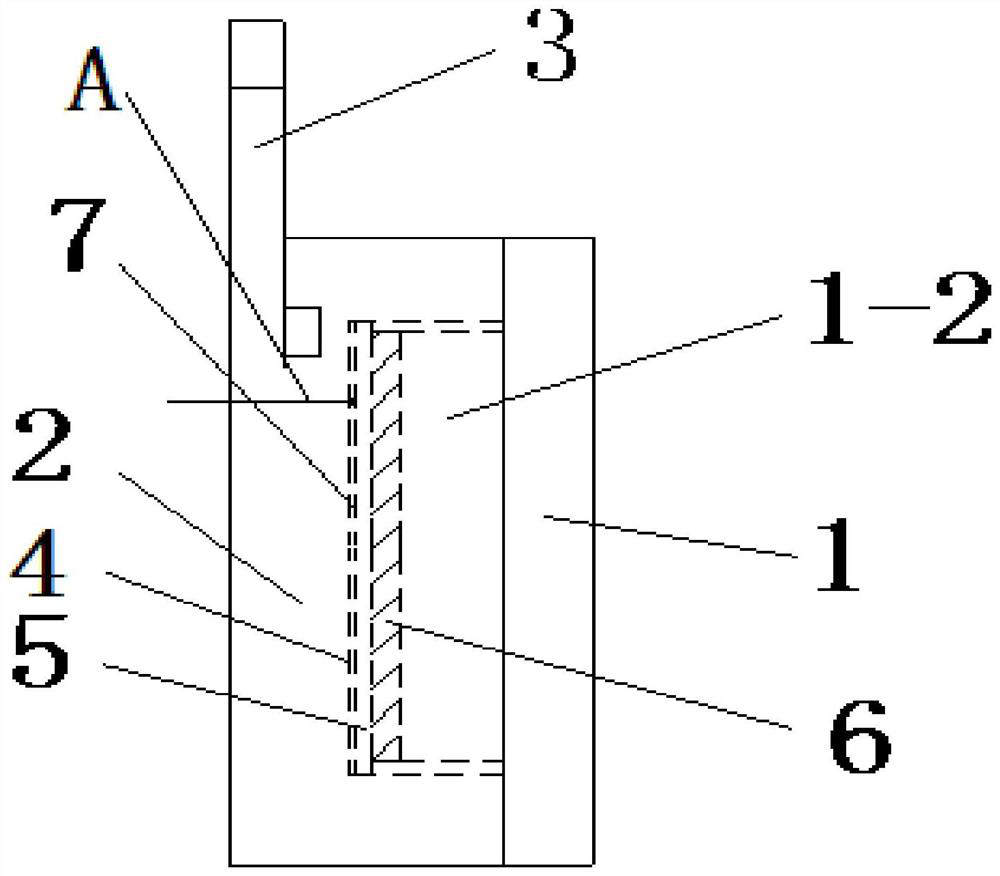

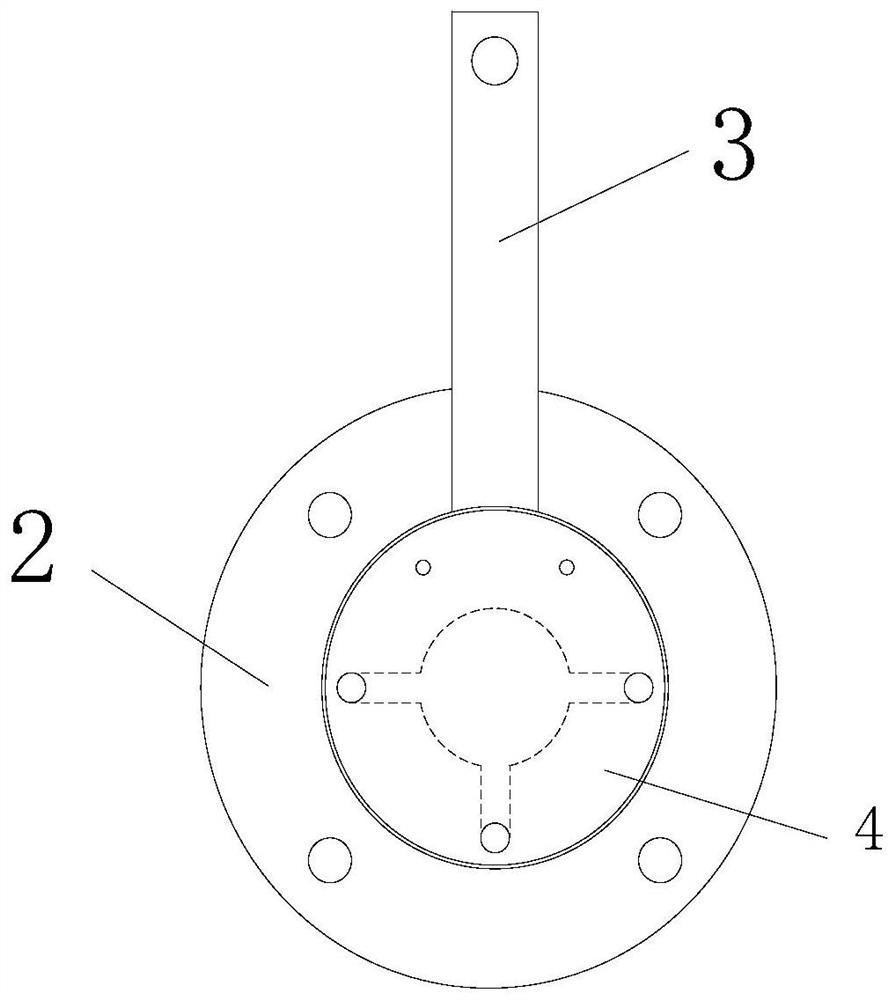

[0030] Embodiment 1: Combining Figure 1-Figure 11 Illustrate this embodiment, a kind of clamp made of graphene suspension film into capacitor described in this embodiment,

[0031]It includes an upper end cover 1, a lower end cover 2, a negative electrode plate 3, a sheet 4 and a positive lead wire A. The upper end cover 1 and the lower end cover 2 are fixedly installed with screws, and the negative electrode plate 3 is installed in the lower end cover 2. The upper end cover 1 includes The plate body 1-1 and the boss 1-2, a boss 1-2 is machined at the center of the lower surface of the plate body 1-1, and a first through hole 1-1-1 is machined at the center of the plate body 1-1, The first through hole 1-1-1 is to allow the graphene suspension film to receive a sound signal with a certain sound intensity, the lower end cap 2 is a cylinder, and a first groove 2-1 is processed on the center of the upper surface of the cylinder. , a second through hole 2-2 and two first positiv...

specific Embodiment approach 2

[0032] Specific implementation mode 2: Combining figure 2 Describe this embodiment, a kind of fixture that makes graphene suspension film into capacitor described in this embodiment, each positive lead wire A and graphene suspension film 7 are connected by flexible conductive glue, so set, ensure that each positive lead wire The good contact between A and the graphene suspension film 7 increases the contact area between the positive electrode lead wire A and the graphene suspension film 7, which reduces the contact resistance. As for the thickness of a small amount of conductive adhesive, because it is flexible, The thickness of the upper end cap 1 and the lower end cap 2 can be squeezed by adjusting the screws of the upper end cap 1 and the lower end cap 2 of the clamp. After the purpose of reducing the contact resistance is achieved, the influence on the parallelism of the two electrode plates of the capacitor can be reduced as much as possible. Others are the same as the fi...

specific Embodiment approach 3

[0033] Specific implementation three: combination Figure 5 Illustrating this embodiment, a clamp for making a graphene suspension film into a capacitor described in this embodiment, the upper end cap 1 is circular, the diameter of the boss 1-2 is smaller than the diameter of the plate body 1-1, and the plate body 1- The height of 1 is less than the height of the boss 1-2, so set up in this way, if the plate body 1-1 is only a cover without a boss 1-2, then from the plate body 1-1 of the upper end cover 1 to the lower end cover 2 The bottom needs to be filled, and the more filling material, the more uneven the pressure transmitted to the silicon wafer. This setting reduces the possibility of chipping of the silicon wafer caused by unbalanced force. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com