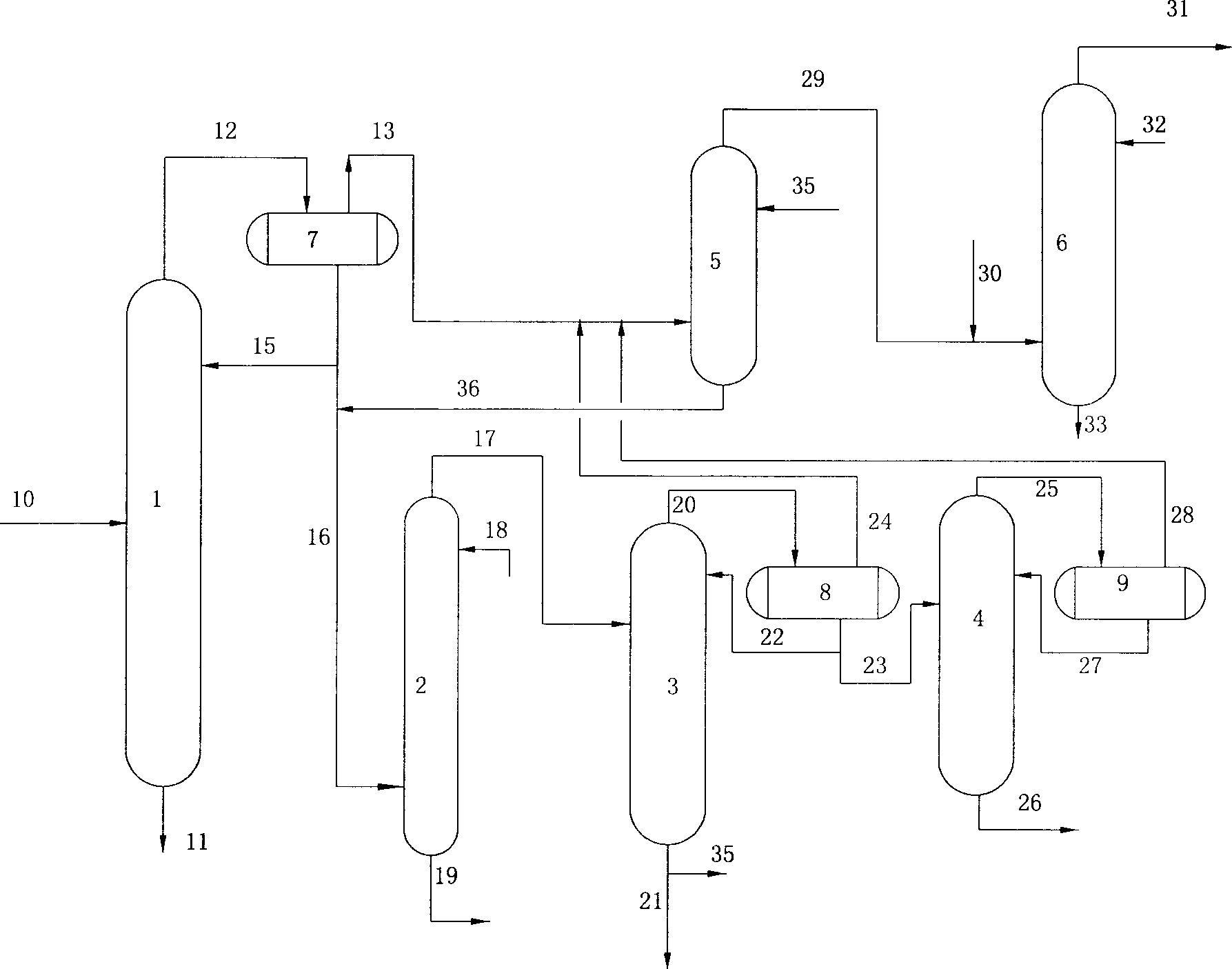

Method for separating hydrocarbon hydrocracking products

A hydrocracking and separation method technology is applied in the field of separation of hydrocarbon hydrocracking products, which can solve the problems of increasing a naphtha fractionator, increasing one-time investment and operating costs, increasing energy consumption, etc. The effect of solving the problem of hydrogen sulfide corrosion and liquefied gas desulfurization and avoiding the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] h 2 S

[0033] It can be concluded from the above table: 1. The hydrogen sulfide content in the bottom of the stabilization tower 1 is approximately zero, which greatly reduces the material corrosion problem currently existing in this tower; 2. The bottom stream of the deethanizer 4 can be used as a liquefaction The petroleum gas product is directly discharged from the device, and the product does not contain hydrogen sulfide. Under this working condition, the mass recovery rate of the low-fraction oil relative to the fractionated part of the feedstock is 99.64%. The recovery rate can be adjusted by adjusting the operating parameters of the debutanizer 3 3. Since the bottom stream of stabilization tower 1 and debutanizer 3 does not contain hydrogen sulfide, the problem of unqualified hydrogen sulfide corrosion of light oil products such as naphtha is avoided to a large extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com