Manufacturing method of prefabricated bending integrated materials

A manufacturing method and technology of laminated wood, which are applied in the direction of bending of wood, joining of wooden veneers, manufacturing tools, etc., can solve the problems of deformation, unusability on the engineering site, springback, etc., and achieve low cost, simple and feasible manufacturing method, The effect of solving the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

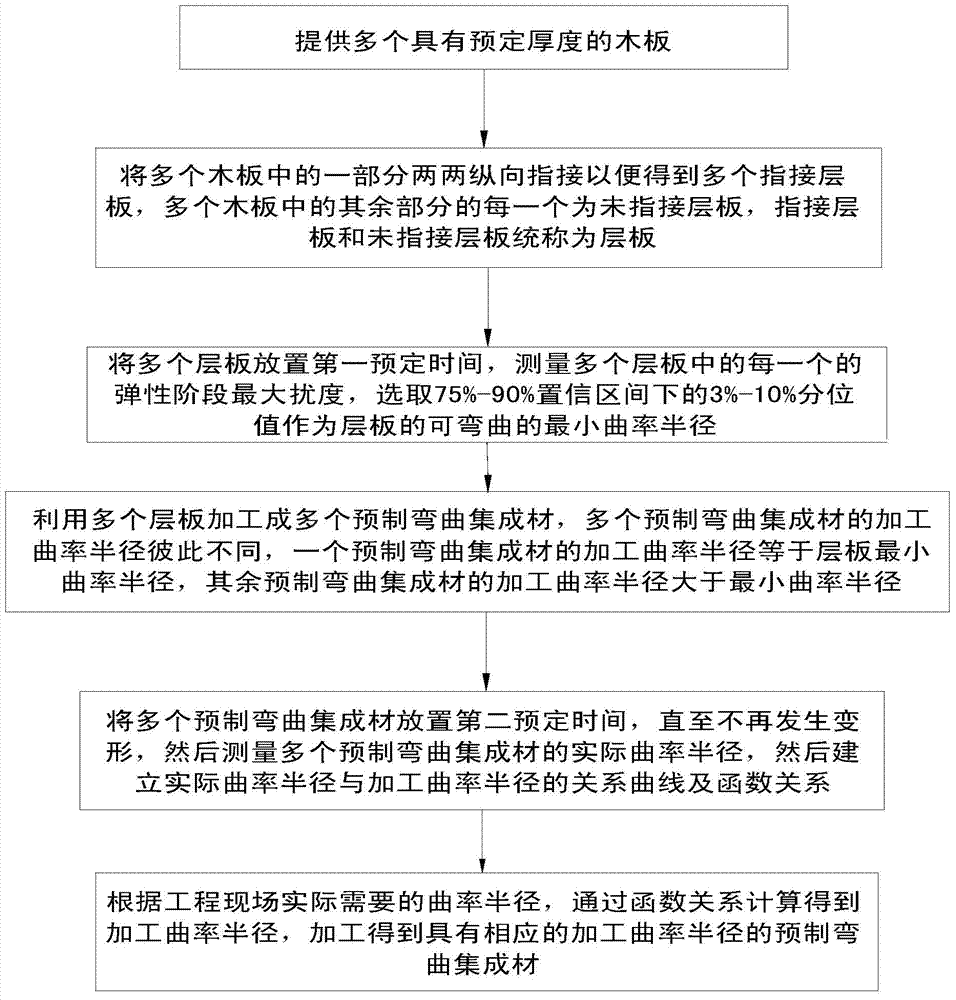

[0017] A method for manufacturing a prefabricated curved glulam according to an embodiment of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 As shown, the manufacturing method of the prefabricated curved glulam according to the embodiment of the present invention includes the following steps:

[0018] providing a plurality of planks with a predetermined thickness;

[0019] A part of the plurality of wood boards is finger-joined two by two longitudinally so as to obtain a plurality of finger-joined laminates, and each of the remaining parts of the plurality of wood boards is an un-fingered laminate, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com