Apparatus for repairing circuit pattern and method for manufacturing display apparatus using the same

A technology of graphics and inspection devices, applied in nonlinear optics, instruments, optics, etc., to achieve the effects of improving display quality, improving correction accuracy, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Generally, a liquid crystal display device is a structure in which liquid crystal is sandwiched between two glass substrates, and the molecules of liquid crystal in each pixel are affected by the electric field in the capacitor formed by the pixel electrodes of multiple images arranged in a matrix, the opposite electrode and the liquid crystal. The orientation is controlled to generate an electronic latent image, and in a transmissive liquid crystal display device, the electronic latent image is visualized to display an image by controlling the transmittance of light from a backlight provided on the back. A color image is displayed by forming a circuit for controlling voltage applied to pixel electrodes on an active matrix substrate, and forming, for example, three-color color filters on a color filter substrate.

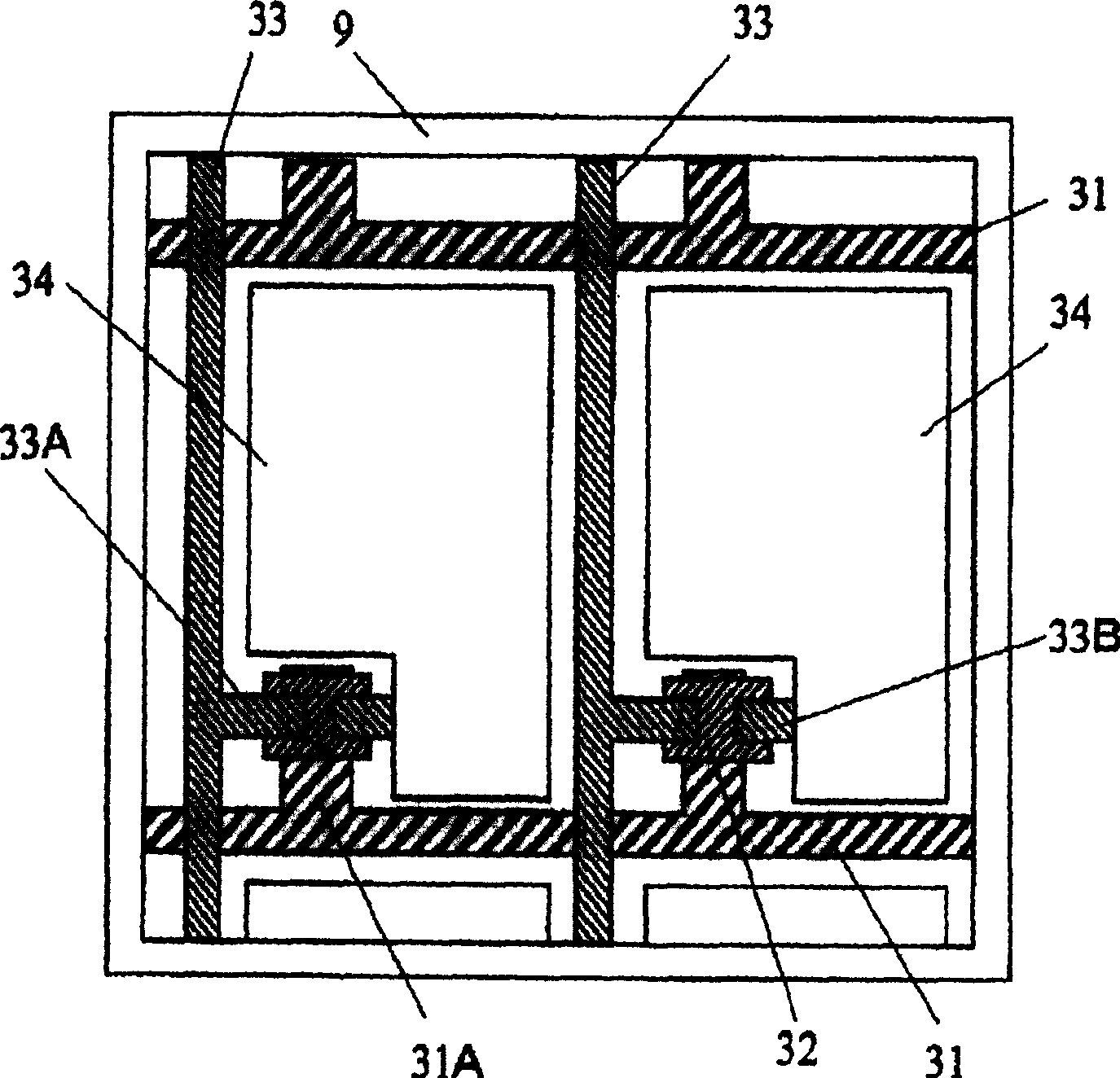

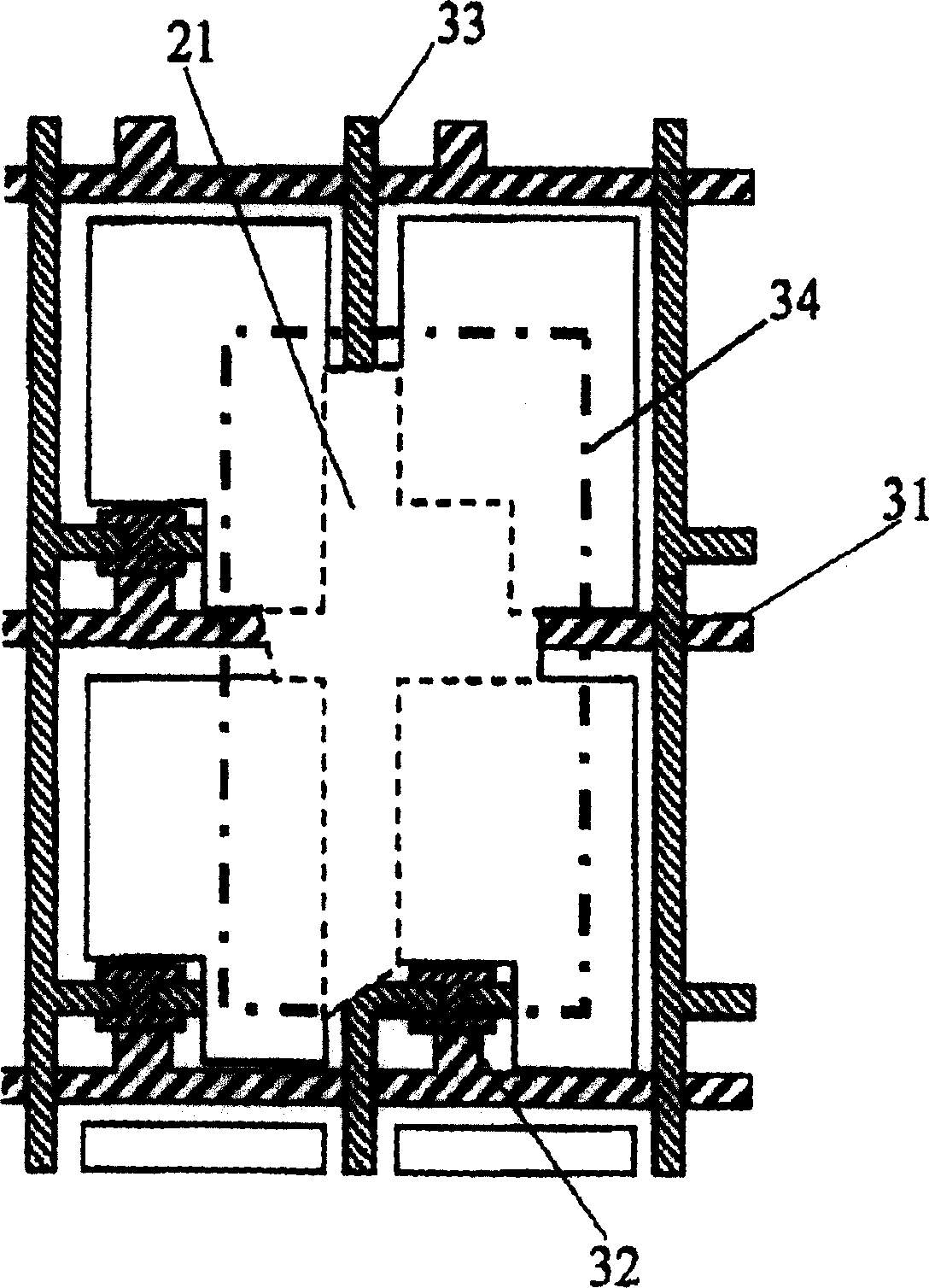

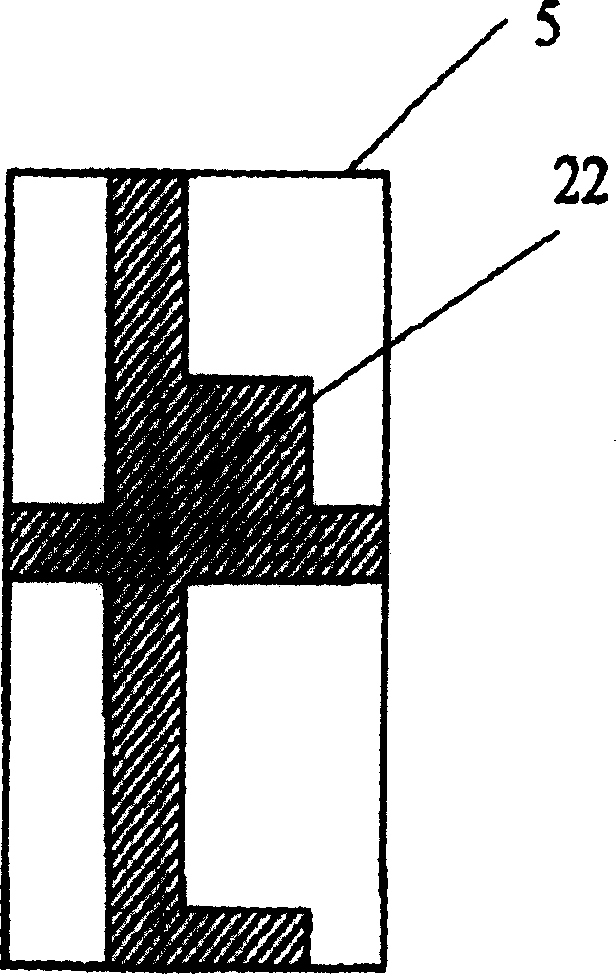

[0078] figure 1 This is a schematic plan view illustrating an example of pixels formed on an active matrix substrate of a liquid crystal display device. ex...

Embodiment 2

[0143] Figure 26 For illustrating the process diagram of embodiment 2 of the present invention. Figure 26 A manufacturing process of a glass substrate forming a switching element thin film transistor used in a liquid crystal panel in Example 2 is shown. The glass substrate on which this switching element is formed is generally referred to as a "TFT substrate" or "array substrate", and is hereinafter referred to as a TFT substrate. In Example 2, first, an inorganic film or an organic film is formed on a glass substrate provided when manufacturing a TFT substrate (S10).

[0144] A typical inorganic substance includes a metal material constituting the wiring of the TFT substrate. A photoresist is coated on the film-formed glass substrate and fired (S11).

[0145] Here, the so-called photoresist is a photosensitive material, which is used to process the film-forming material into a predetermined shape. Thereafter, by exposing the photoresist to light (S12), the photoresist i...

Embodiment 3

[0152] Figure 27 For illustrating the process diagram of embodiment 3 of the present invention. exist Figure 27 In , the manufacturing process of the TFT substrate used in the liquid crystal panel is shown. In Example 3, first, an inorganic film or an organic film is formed on a glass substrate provided when manufacturing a TFT substrate (S30). Here, since a transparent metal ITO (indium tin oxide) provided on a TFT substrate can be mentioned as a typical inorganic material for film formation, the following description will be made using an ITO film as a representative example.

[0153] At the stage where film formation is completed, visual inspection is performed (S31). Here, since ITO is transparent, it can be seen that there are foreign matter on ITO and foreign matter in the lower layer of ITO. The results of the visual inspection at the film formation completion stage are accumulated in the process of depositing the visual inspection results after film formation ( S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com