Automatic seal ring loading system for lead-acid battery after cover closure

A technology of lead-acid battery and sealing ring, which is applied in the direction of lead-acid battery, lead-acid battery construction, battery assembly machine, etc. It can solve the problems of poor mounting accuracy of sealing rings, improve sealing performance, increase loading speed, and effectively and quickly remove Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

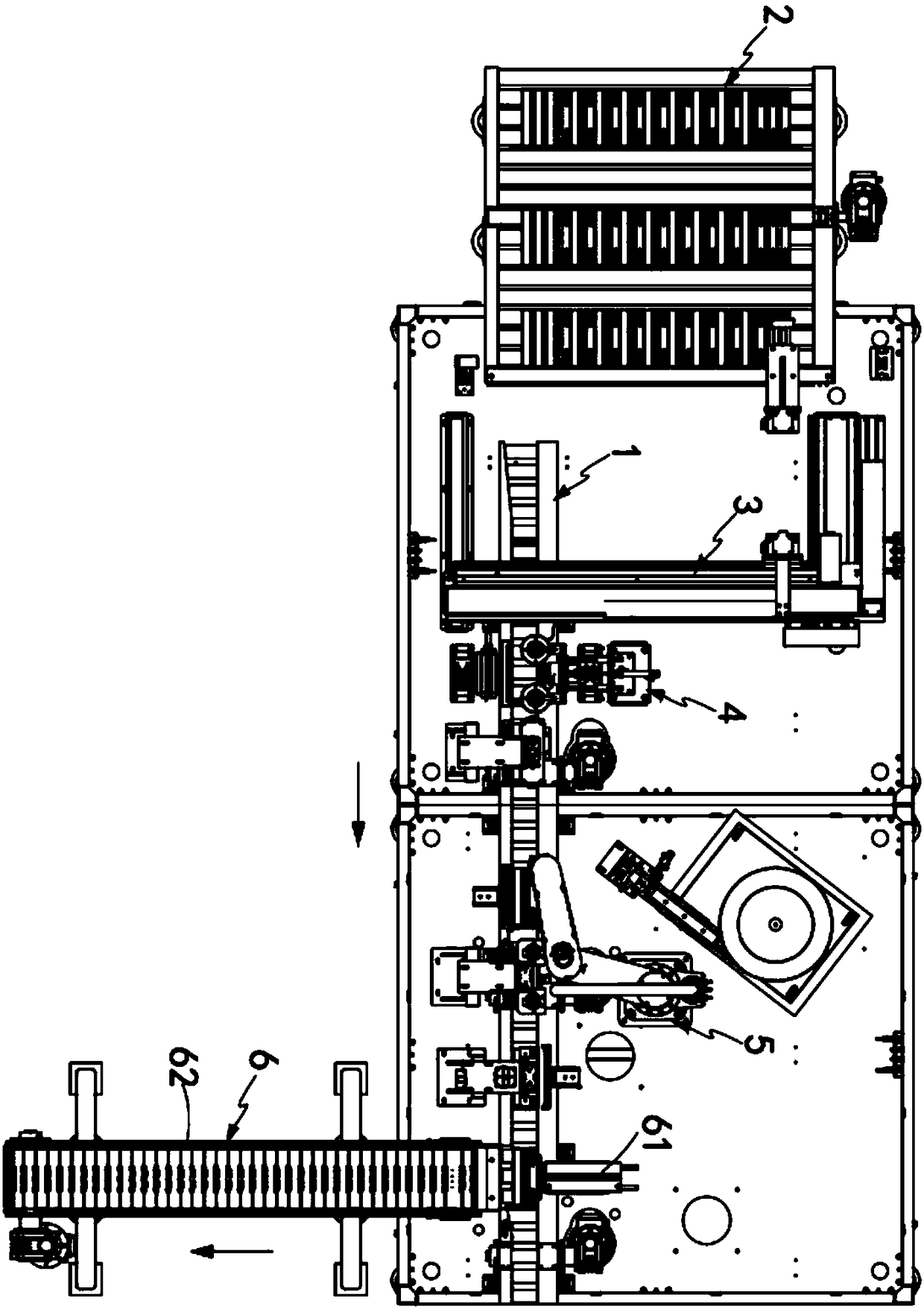

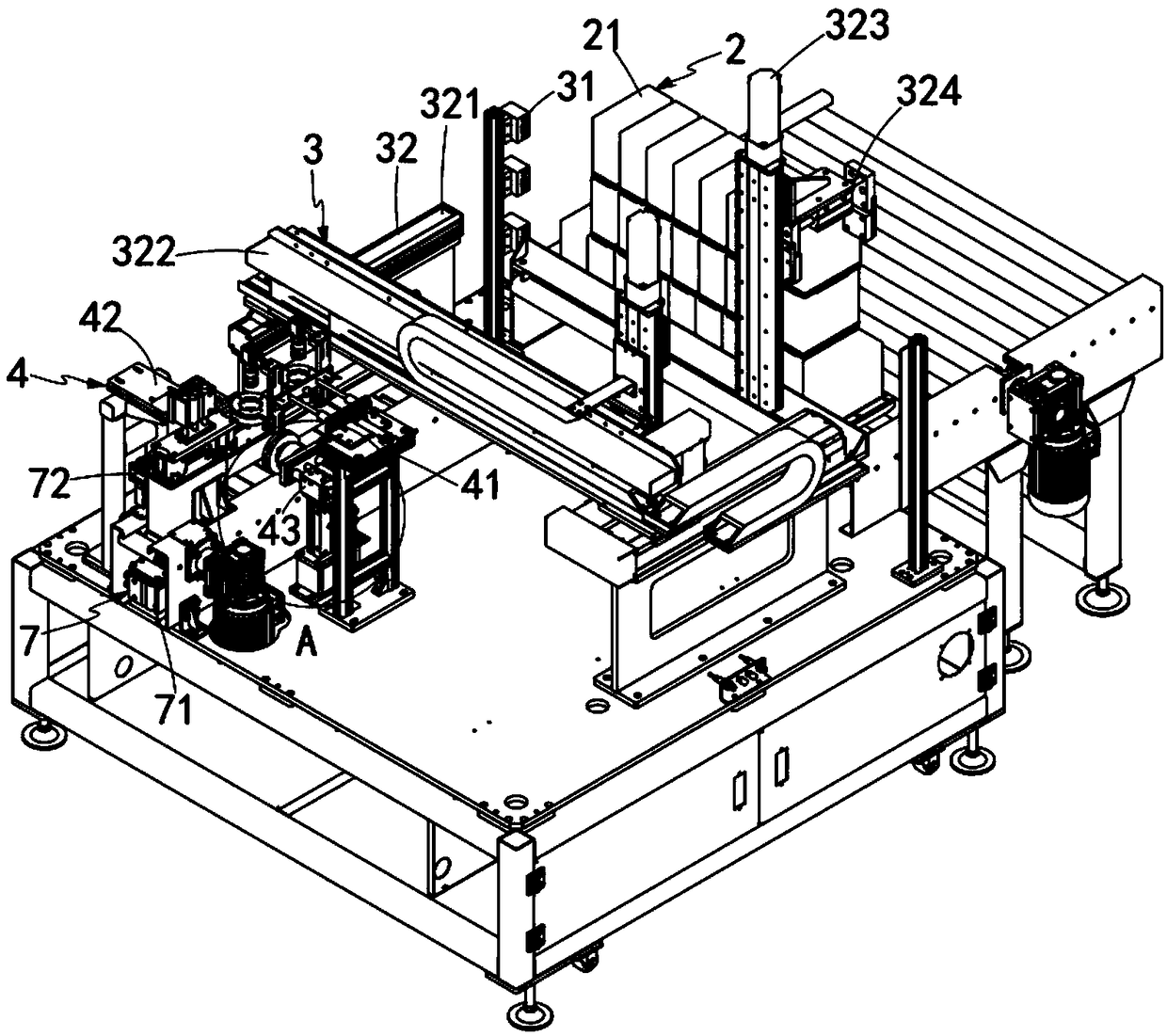

[0072] Such as figure 1 , figure 2 and Figure 7 As shown, a sealing ring automatic loading system after the lead-acid battery is closed includes a conveying mechanism 1, and along the conveying direction of the conveying mechanism 1, it also includes:

[0073] A stock pile 2, the stock pile 2 is arranged at the input end of the conveying mechanism 1, and it includes a plurality of stacked lead-acid batteries 21;

[0074] The feeding device 3, the feeding device 3 is arranged at the rear end of the battery material pile 2, and it includes a plurality of infrared positioners 31 fixedly arranged on one side of the conveying mechanism 1 for positioning the lead-acid batteries 21 and the clamping mechanism 32 arranged above the conveying mechanism 1 to clamp the lead-acid battery 21 movable;

[0075] Detecting and rectifying device 4, said detecting and rectifying device 4 is arranged on the rear side of said feeding device 3, and it includes a device for detecting the vertica...

Embodiment approach

[0102] Such as Figure 10 and Figure 11 As shown, as a preferred embodiment, the upper loading mechanism 52 includes:

[0103] A manipulator 521, the manipulator 521 is rotatably arranged between the conveying mechanism 1 and the sorting disk 51, and one end of the manipulator 521 rotating around its axis is provided with a mounting part 522 that can automatically vertically expand and contract;

[0104] A connection block 523, the connection block 523 is vertically connected with the installation part 522;

[0105] A pick-up head 524, the pick-up head 524 is symmetrically slidably arranged on the connecting block 523, and the end of the pick-up head 524 is provided with an annular pick-up portion 525 for taking the sealing ring 50; and

[0106] The elastic member 526 is vertically sheathed on the material picking head 524 , and the two ends of the elastic member 526 are arranged between the connecting block 523 and the material picking head 524 respectively.

[0107] It s...

Embodiment 2

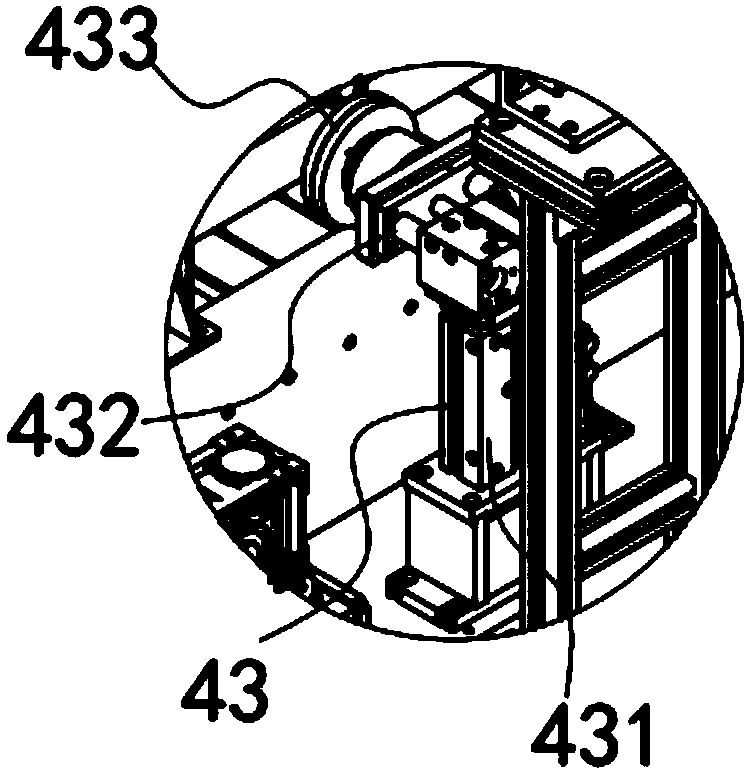

[0120] image 3 It is a structural schematic diagram of Embodiment 2 of the sealing ring automatic loading system after a lead-acid battery is closed; image 3 As shown, the parts that are the same as or corresponding to the first embodiment adopt the corresponding reference numerals of the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The second embodiment is similar to the first embodiment. figure 1 The difference of the shown embodiment one is:

[0121] An automatic loading system for the sealing ring after the lead-acid battery is closed, the overturning mechanism 43 is arranged directly under the detection mechanism 41, and the overturning mechanism 43 includes:

[0122] Lifting cylinder 431, the lifting cylinder 431 is symmetrically arranged on both sides of the conveying mechanism 1, and the pushing direction of the lifting cylinder 431 is vertically arranged with the conveying direction of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com