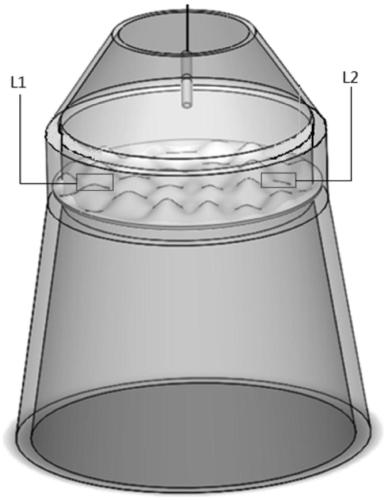

A method and system for three-dimensional reconstruction of blast furnace charge surface based on monocular imaging

A blast furnace material surface, three-dimensional reconstruction technology, applied in image analysis, image enhancement, image data processing and other directions, can solve the problems of few feature points, poor blast furnace material surface model accuracy, large errors, etc., to achieve the effect of improving model accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

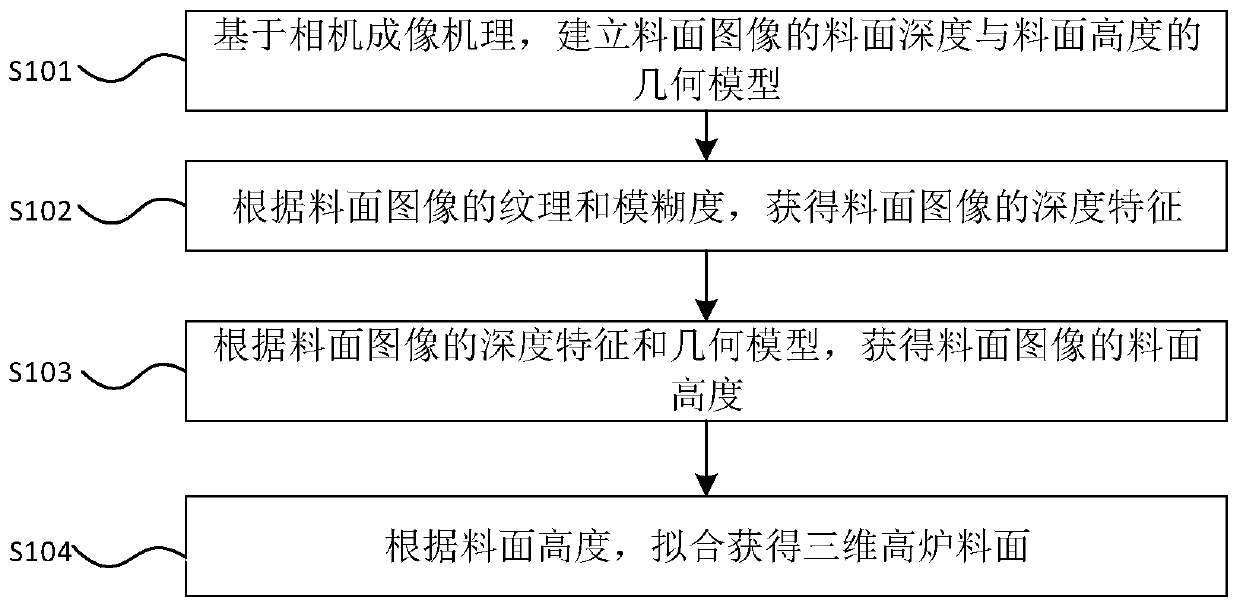

[0054] refer to figure 2 , the method for three-dimensional reconstruction of blast furnace charge surface based on monocular imaging provided in Embodiment 1 of the present invention includes:

[0055] Step S101, based on the imaging mechanism of the camera, a geometric model of the material surface depth and the material surface height of the material surface image is established;

[0056] Step S102, obtaining the depth feature of the material surface image according to the texture and blur of the material surface image;

[0057] Step S103, according to the depth feature and the geometric model of the material level image, the material level height of the material level image is obtained;

[0058] Step S104, according to the height of the material level, the three-dimensional blast furnace material level is obtained by fitting.

[0059] The three-dimensional reconstruction method of the blast furnace material level based on monocular imaging provided by the embodiment of ...

Embodiment 2

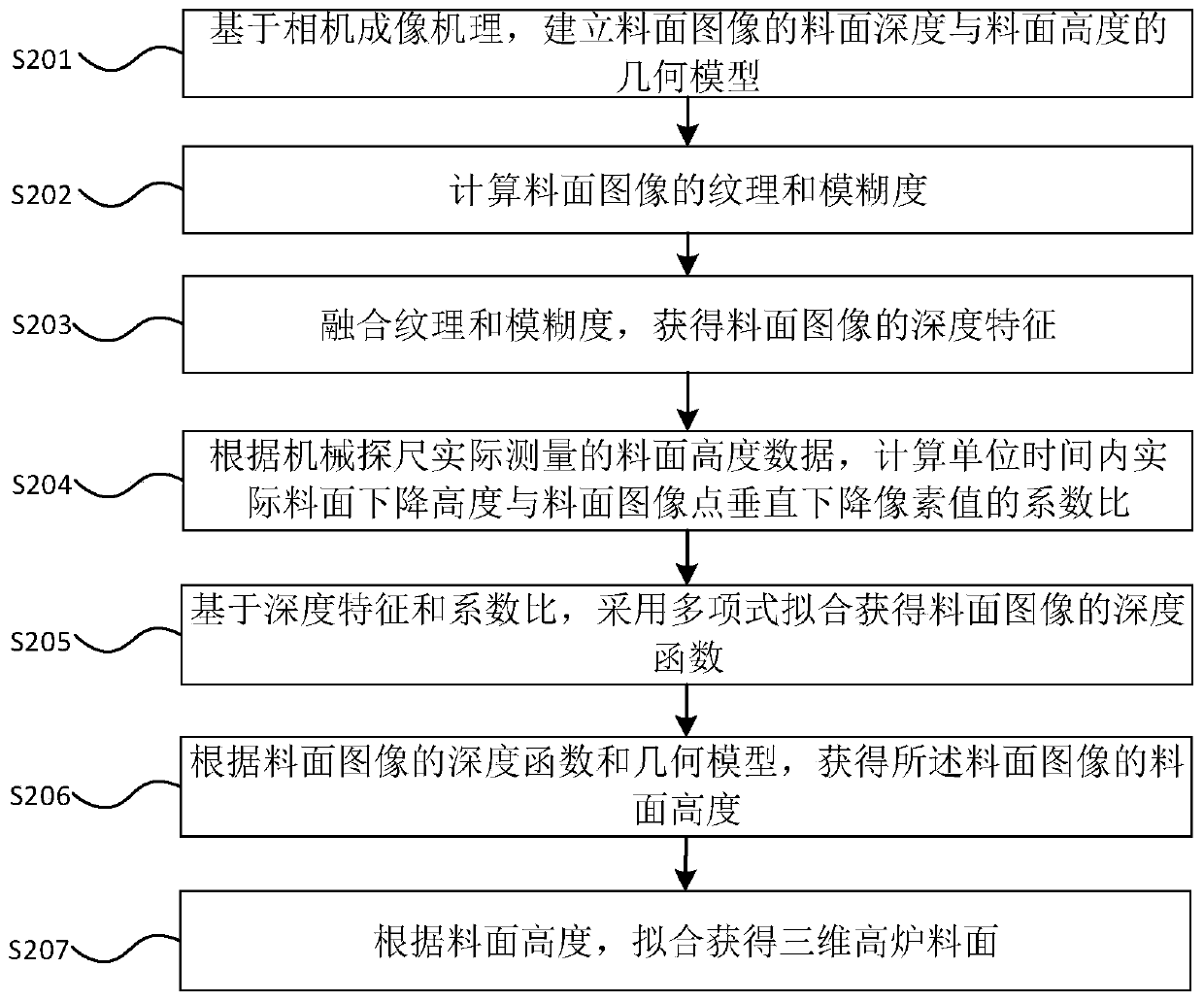

[0062] refer to image 3 , the method for three-dimensional reconstruction of blast furnace charge surface based on monocular imaging provided in Embodiment 2 of the present invention includes:

[0063] Step S201, based on the imaging mechanism of the camera, a geometric model of the material level depth and material level height of the material level image is established.

[0064] Specifically, in the embodiment of the present invention, based on the camera imaging mechanism, establishing a geometric model of the material level depth and material level height of the material level image includes:

[0065] The material surface image is equally divided into M*N sub-material surface images of the same size, wherein M and N are integers greater than 1;

[0066] Based on the camera imaging mechanism, the average material surface height of each sub-surface image is obtained as:

[0067]

[0068] Among them, h j,i is the average material surface height of the (j,i)th sub-surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com