Uniform-section ultra-thin-wall bearing ring turning machining technique

A technology for bearing rings and processing technology, which is applied in the field of turning processing technology for ultra-thin-walled bearing rings with cross-sections, and can solve problems such as deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and effects adopted by the present invention to achieve the predetermined invention purpose, the following is a concrete implementation of the turning process method of the equal-section ultra-thin-walled bearing ring according to the present invention in conjunction with the accompanying drawings and preferred embodiments Mode, structure, feature and effect thereof are as follows in detail.

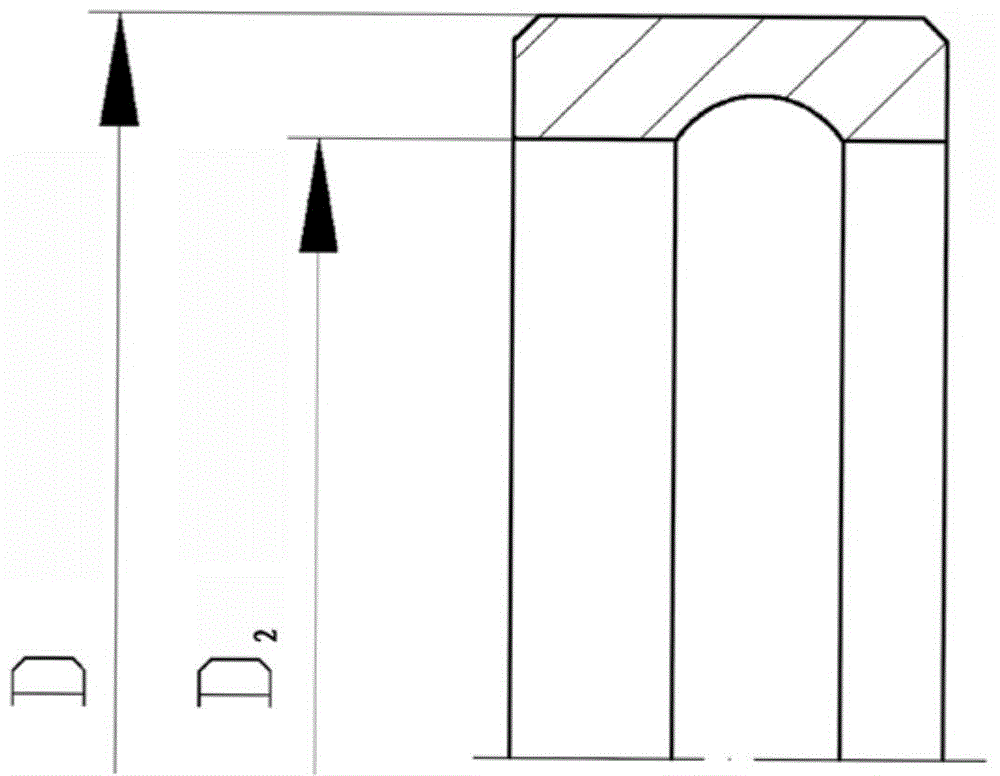

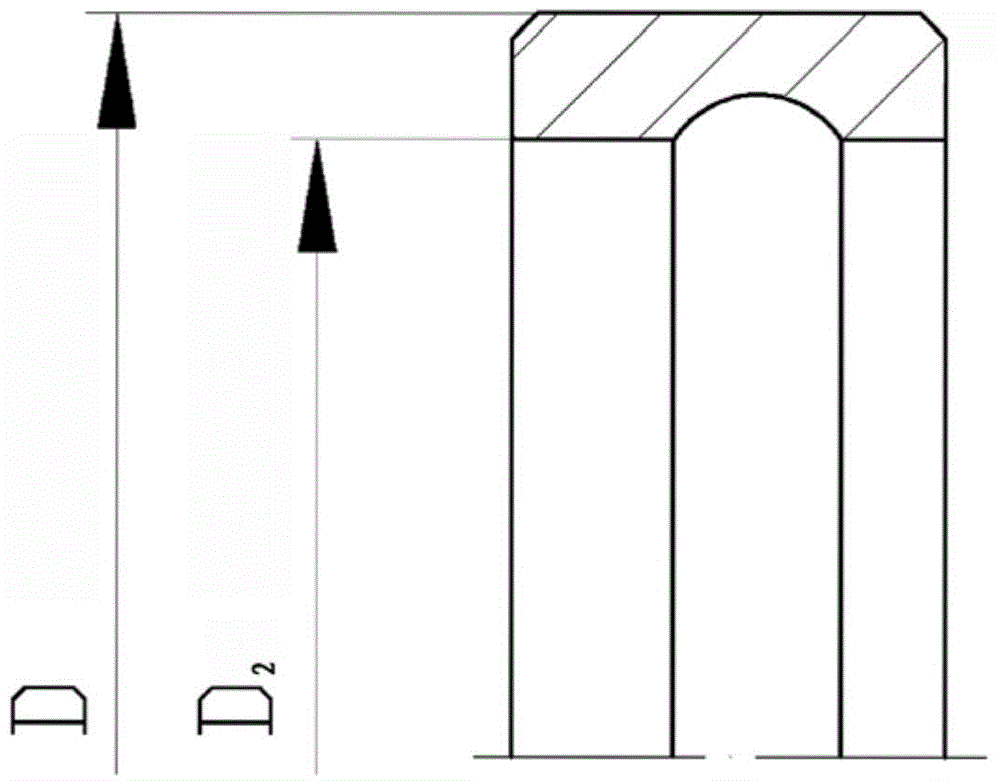

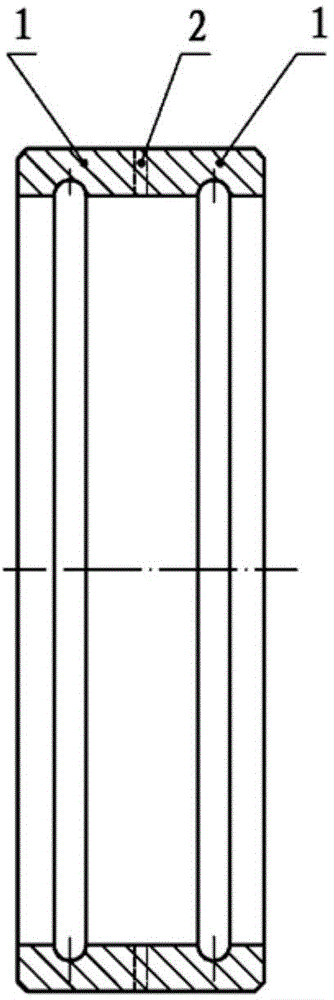

[0024] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 as shown, figure 1 It is a schematic diagram of the finished bearing ring of the present invention. figure 2 It is a schematic diagram of the finished bearing ring of the present invention. image 3 It is a schematic diagram of the processing of the bearing ring assembly of the present invention. Figure 4 It is a schematic diagram of the processing of the bearing ring assembly of the present invention. Figure 5 It is a schematic diagram of machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com