Thin-wall piece lathe clamp

A technology for turning fixtures and thin-walled parts is applied in the field of machining fixtures, which can solve problems such as workpiece deformation and achieve the effect of meeting the requirements of processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

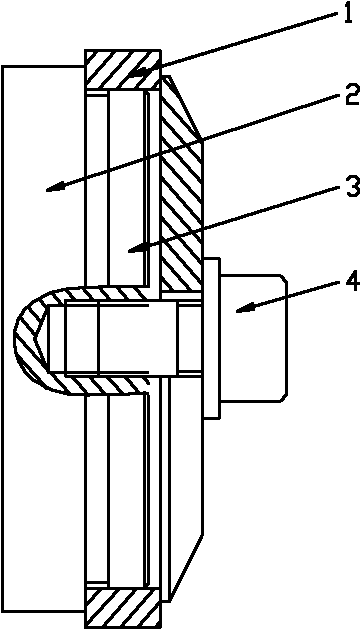

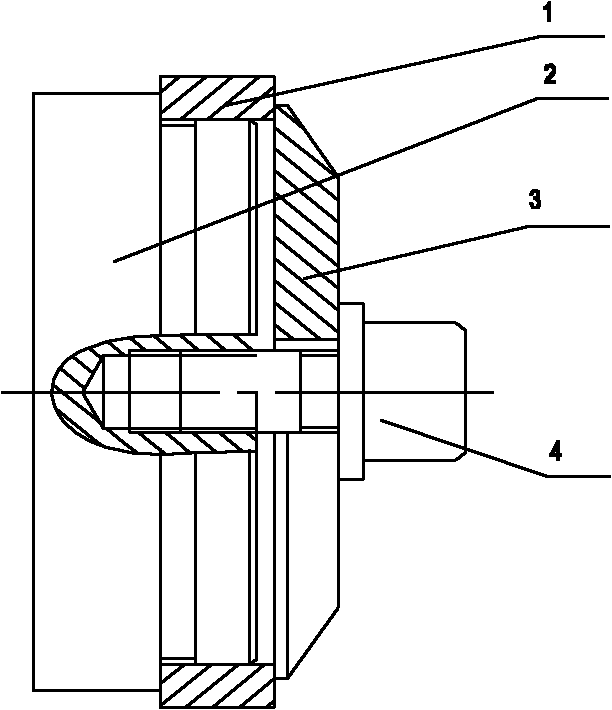

[0011] Such as figure 1 As shown, the thin-walled parts turning fixture includes two sets of fixtures: the turning fixture and the turning fixture; The clamp body 6 clamps the outer circle of the workpiece 1 . According to the lathe processing procedure, turn the outer circle first: take the end surface of the workpiece 1 as the reference plane, position on the mandrel 2, and center it with the inner hole; press the workpiece 1 with the gland 3, and tighten the screw 4. The diameter of the cover 4 is smaller than the nominal diameter of the workpiece 1, leaving enough Workpiece 1 processing volume. Start the machine tool to start turning the outer circle, and keep a certain margin for finishing turning when turning the outer circle.

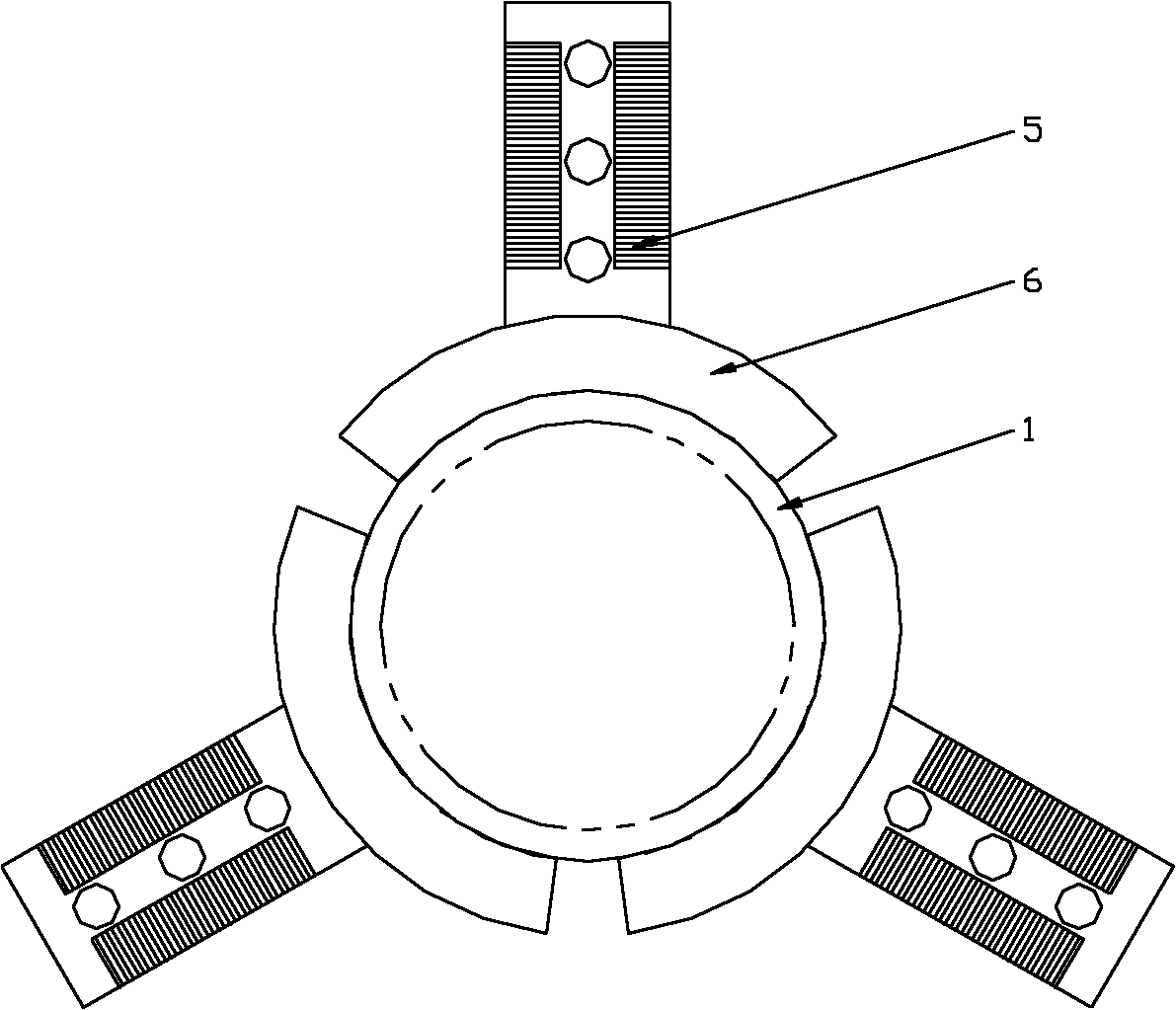

[0012] Such as figure 2 As shown, after the outer circle is turned, the inner hole and the end face of the outer circle are clamped. The clamp body 6 clamps the outer circle of the workpiece 1, and the clamp body is welded to the chuck jaw 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com