Oil-saving rotational molding diesel oil tank material and preparation method thereof

A technology for diesel and oil tanks, applied in mechanical equipment, charging systems, liquid fuel feeders, etc., can solve the problems of material performance degradation, uneven dispersion of tourmaline powder and negative ion powder, poor compatibility of polyethylene, etc., to achieve easy Mass production, significant economic and social benefits, and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

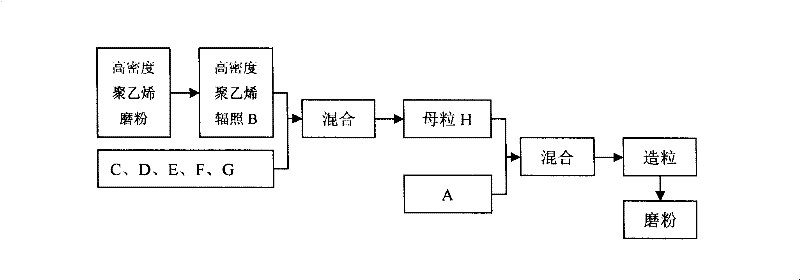

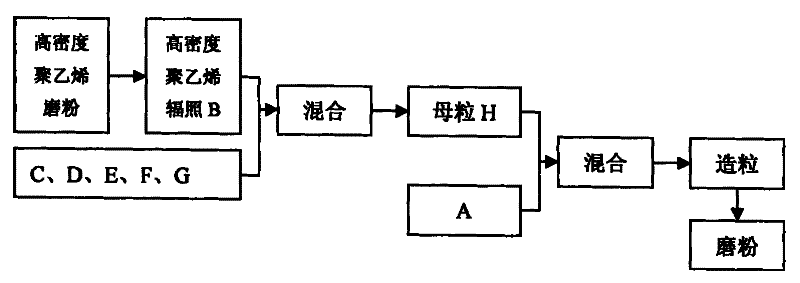

Method used

Image

Examples

Embodiment 1

[0046] formula:

[0047] (A) Linear low density polyethylene PE500U with a mass percentage of 50%;

[0048] (B) 21% by mass irradiated high-density polyethylene PE5000S;

[0049] (C) Tourmaline powder with 10% mass percentage;

[0050] (D) Anion powder with a mass percentage of 10%;

[0051] (E) 5% by mass antistatic agent (204P:501P=4:1);

[0052] (F) 2% by mass antioxidant (1010:168=1:1);

[0053] (G) Leveling agent HL-200 with a mass percentage of 2%.

[0054] The above-mentioned components are prepared by the following process methods to produce rotomolding diesel fuel tank materials:

[0055] 1. Raw material processing

[0056] Under the technological conditions of a rotation speed of 4000 rpm and a grinding plate temperature of 55°C, the high-density polyethylene PE5000S is ground into a powder of 35 mesh or more in a plastic mill, placed in a closed container, and heated to 50°C At the same time, the air in the container is replaced by ozone, and the ultraviolet irradiation device is...

Embodiment 2

[0065] formula:

[0066] (A) Linear low-density polyethylene with a mass percentage of 50%;

[0067] (B) 47.7% by mass of irradiated high-density polyethylene;

[0068] (C) Tourmaline powder with a mass percentage of 1%;

[0069] (D) Anion powder with a mass percentage of 1%;

[0070] (E) 0.1% by mass antistatic agent (204P:501P=2:1);

[0071] (F) 0.1% by mass antioxidant (1010:168=1:4);

[0072] (G) 0.1% by mass leveling agent.

[0073] The above-mentioned components are prepared by the following process methods to produce rotomolding diesel fuel tank materials:

[0074] 1. Raw material processing

[0075] Under the technological conditions of a rotation speed of 5000 rpm and a grinding disc temperature of 65°C, the high-density polyethylene is ground into a powder of 35 mesh or more in a plastic mill, placed in a closed container, and heated to 60°C. At the same time, the air in the container is replaced with ozone, and the ultraviolet irradiation device is turned on for 20 minutes to irr...

Embodiment 3

[0084] formula:

[0085] (A) Linear low-density polyethylene with a mass percentage of 50%;

[0086] (B) 38.6% by mass irradiated high-density polyethylene;

[0087] (C) 5% by mass tourmaline powder;

[0088] (D) Anion powder with a mass percentage of 3%;

[0089] (E) 2% by mass antistatic agent (204P:501P=3:1);

[0090] (F) 0.6% by mass of antioxidant (1010:168=1:2);

[0091] (G) 0.8% mass percentage leveling agent.

[0092] The above-mentioned components are prepared by the following process methods to produce rotomolding diesel fuel tank materials:

[0093] 1. Raw material processing

[0094] Under the technological conditions of rotating speed of 3200 rpm and grinding plate temperature of 50°C, the high-density polyethylene is ground into a powder of 35 mesh or more in a plastic mill, placed in a closed container, and heated to 40°C. At the same time, the air in the container is replaced by ozone, and the ultraviolet irradiation device is turned on for 10 minutes to irradiate the high-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com