Multi-directional die forging process testing device

A process test, multi-directional die forging technology, applied in forging/press/hammer devices, driving devices of forging presses, manufacturing tools, etc., can solve problems affecting the machining accuracy of multi-directional die forging devices, uneven horizontal force Forging and other problems cannot be used to achieve the effect of improving equipment production efficiency and ensuring die forging accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

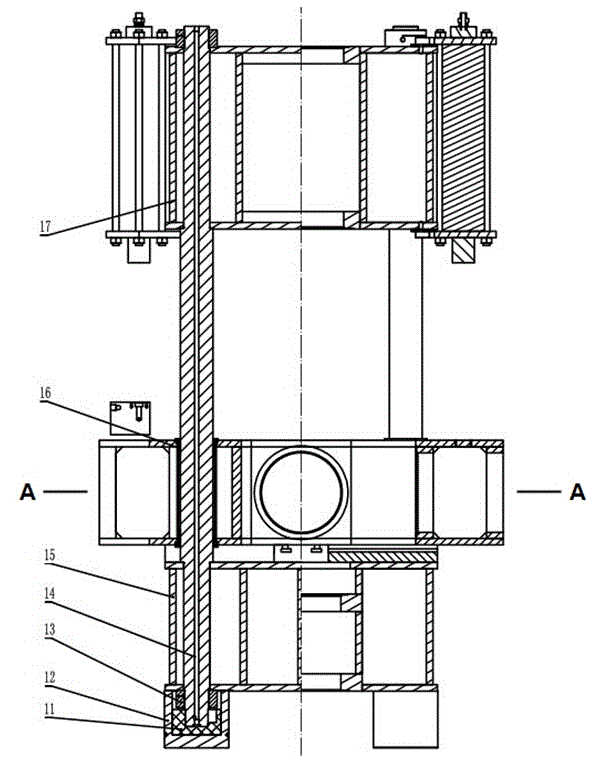

[0016] Specific embodiments of the present invention are described below with reference to the accompanying drawings.

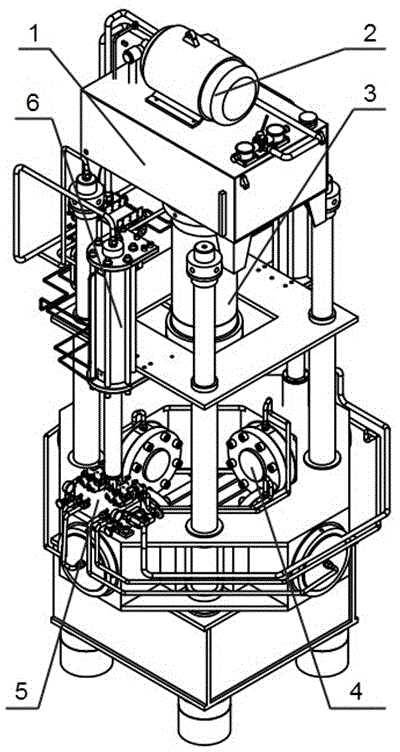

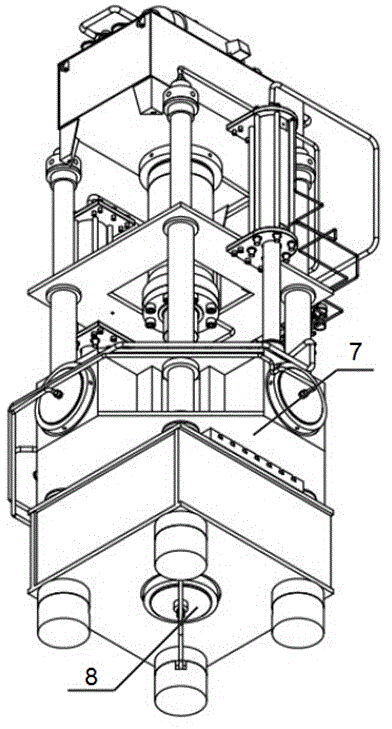

[0017] refer to figure 1 -4. The overall structure of the multi-directional die forging process test device of the present invention is described below:

[0018] The multi-directional die forging process test device includes frame-type main frame (1), hydraulic pump station (2), upper main pressure cylinder (3), four side cylinders (4), valve group (5), two lifting cylinders ( 6), moving beam (7) and lower main pressure cylinder (8) and other components.

[0019] The main frame (1) is made up of nylon pad (11), leg body (12), pull bar (14), lower beam (15), upper beam (17) and workbench (21). The nylon pad (11) is lined inside the foot body (12), which can play a buffering role, thereby greatly reducing the impact of vibration during the working process of the device; the foot body (12) is fixed with the lower beam (15) by welding, and the foot The body (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com