Synthetic ester environment-friendly type aluminum alloy cutting emulsified oil and preparing method thereof

A technology for synthesizing esters and emulsified oils, which is applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problems of poor resistance to hard water, easy oxidation and deterioration, and large discharge of waste liquid, so as to enhance the ability of hard water resistance and resist Effects of microbial erosion and high lubricating cooling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

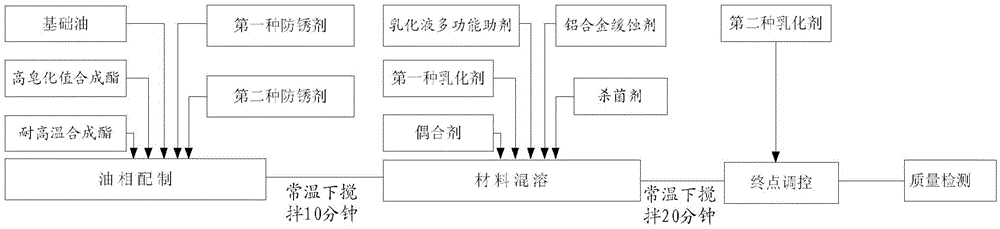

Method used

Image

Examples

Embodiment 1

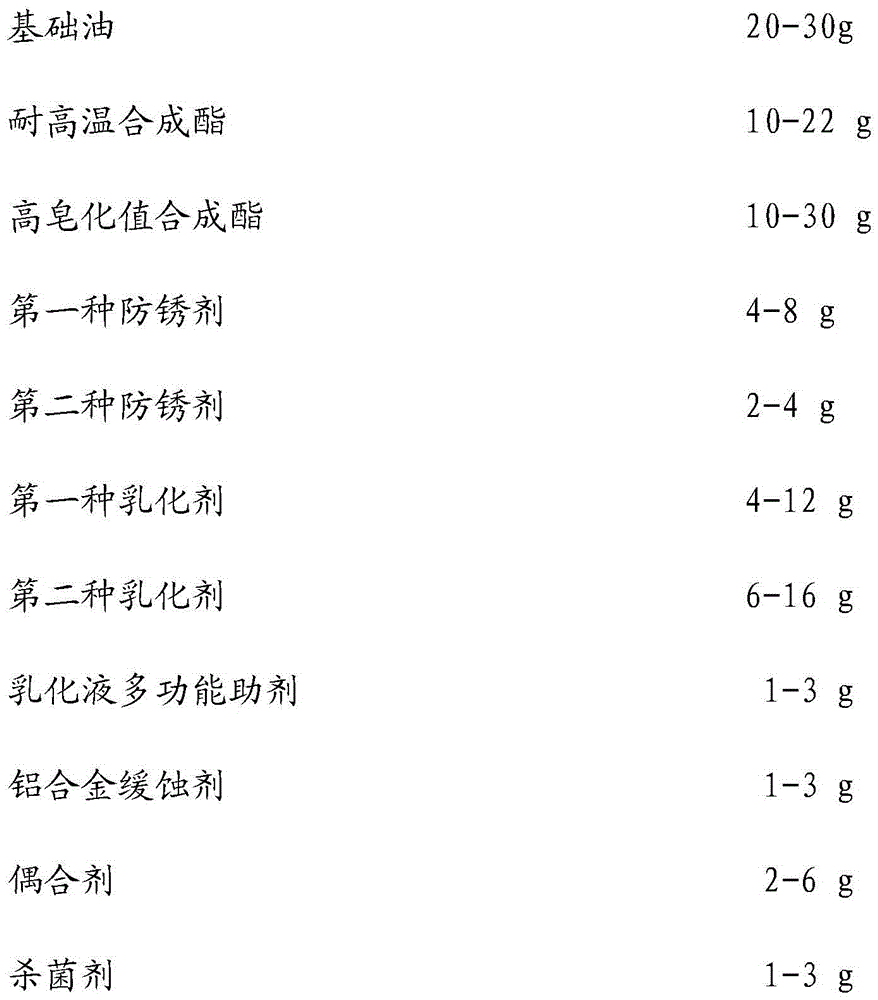

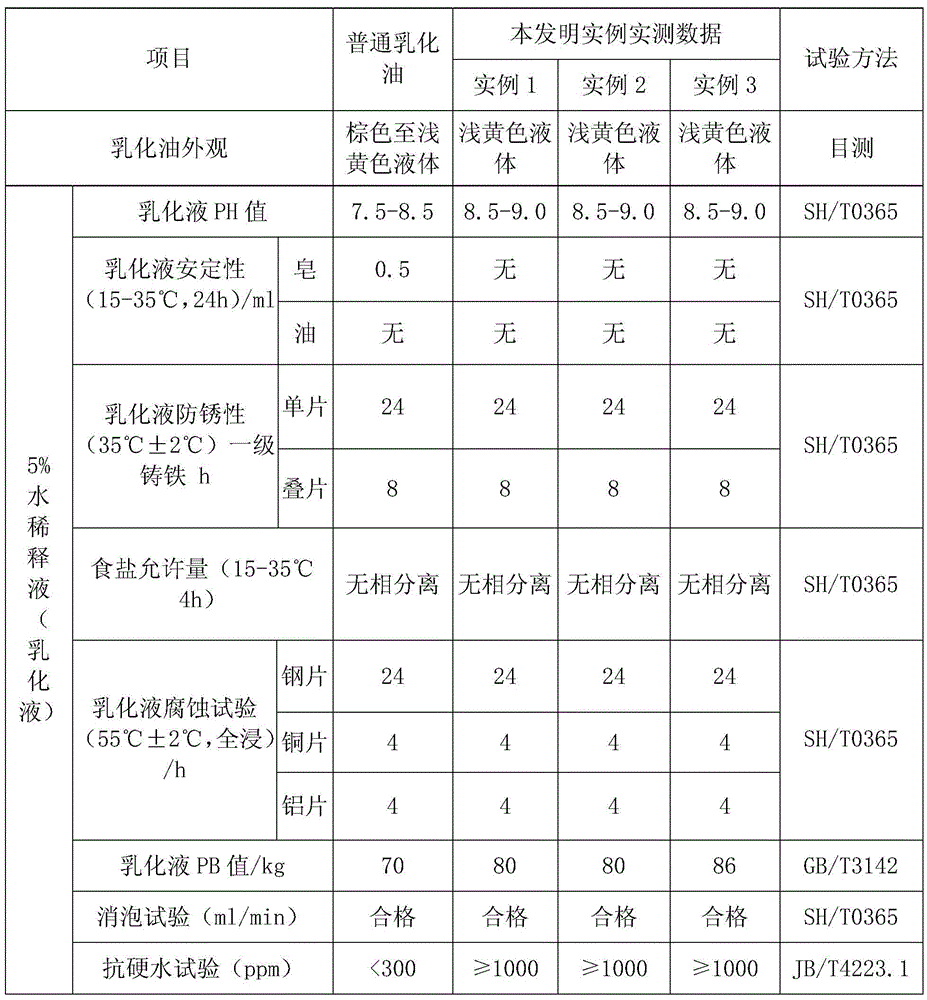

[0038] Prepare synthetic ester environment-friendly type aluminum alloy cutting emulsified oil of the present invention (calculate adding material weight with preparation 100g product) by above-mentioned process flow diagram of the present invention, its steps are as follows:

[0039] Step (1) Preparation of base oil: 22g of 150SN paraffinic base oil and 17g of naphthenic oil with similar viscosity were mixed to prepare 39g of base oil;

[0040] Step (2) Preparation of emulsion oil phase components: 39g base oil; 12g trimethylolpropane trioleate, 18g methyl oleate, 6g first rust inhibitor (T702), 2g second rust inhibitor Add the agent (T747) into the blending tank and stir for 10 minutes until the oil is clear and transparent;

[0041] Step (3) In the blending tank, add 8g of polyethylene glycol 400 laurate, 2g of 2-amino-dimethylsulfone-1-propanol, 1g of Casson fungicide, aluminum alloy corrosion inhibitor OP-NF- 31g, coupling agent diethylene glycol 3g, stirred at room temp...

Embodiment 2

[0045] The preparation method is the same as above, and the specific steps are as follows:

[0046] Step (1) preparation of base oil: 28g of 150SN paraffin base oil and 22g of naphthenic oil with similar viscosity are prepared to obtain 50g of base oil;

[0047] Step (2) prepare emulsion oil phase components: 50g base oil; 12g glyceryl trioleate, 11g pentaerythritol tetraoleate, 6gT702 antirust agent, 2gT746 antirust agent are added in the blending tank, stirred for 10 minutes, until The oil is clear and transparent;

[0048] Step (3) In the blending tank, add polyoxyethylene (20EO) sorbitan tristearate 6g, 2-amino-dimethyl-1-propanol 1g, Casson fungicide 1.5g, aluminum Alloy corrosion inhibitor 8190 / 1.5g, coupling agent diethylene glycol 2g, stir at room temperature for 20 minutes;

[0049] Step (4) Under stirring, add 3g of M0A3 fatty alcohol polyoxyethylene ether, then slowly add 6g of SP-80, and stir until clear and transparent. The amount of SP-80 can be slightly added ...

Embodiment 3

[0052] The preparation method is the same as above, and the specific steps are as follows:

[0053] Step (1) preparation of base oil: prepare 25g of 150SN paraffinic base oil and 20g of naphthenic oil with similar viscosity to obtain 45g of base oil;

[0054] Step (2) Preparation of emulsion oil phase components: 45g base oil; 12g glyceryl trioleate, 8g trimethylolpropane trioleate, 5g pentaerythritol tetraoleate (take two samples of high temperature resistant synthetic ester compound use ), 6gT702 antirust agent, 2gT747 antirust agent were added in the mixing tank, stirred for 10 minutes, until the oil liquid was clear and transparent;

[0055] Step (3) In the mixing tank, add 6g of polyethylene glycol 400 laurate, 4g of TX-10 alkylphenol polyoxyethylene ether, 1g of Casson fungicide, aluminum alloy corrosion inhibitor OP-NF-3 / 1g, coupling agent glycerin 2g, stirred at room temperature for 20 minutes;

[0056] Step (4) Slowly add about 8g of SP-80 under stirring until it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com