Chloride-free extreme pressure microemulsion cutting fluid and preparation method therefor

A cutting fluid and extreme pressure technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor lubricity and anti-rust effect, pollute the environment, poor cooling performance, etc., achieve fast cutting speed, good cooling performance, extreme Excellent pressure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

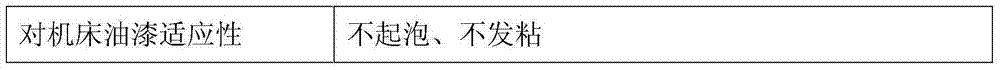

Image

Examples

Embodiment Construction

[0010] A chlorine-free extreme pressure microemulsion cutting fluid, made of the following raw materials in parts by weight (kg): 4.5 boric acid, 1.5 benzotriazole, 1.5 caprylic acid, 1.5 sodium lauryl sulfate, and 3.5 polyacrylamide , urea 2.5, Span 400.9, lanthanum nitrate 0.7, kerosene 13, auxiliary agent 7, water 200; the auxiliary agent is made of the following raw materials in parts by weight (kg): polyoxyethylene sorbitan monooleate 2. Aluminum nitride powder 0.1, alcohol ester twelve 2, tea polyphenol 1, 2-n-octyl-4-isothiazolin-3-one 1, sodium molybdate 2, hydroxyethyl cellulose 5, peach gum 3. Neopentyl glycol 3, ammonium persulfate 1, water 20; the preparation method is to dissolve ammonium persulfate in water, then add other remaining materials, stir for 10-15 minutes, heat to 70-80°C, stir and react 1 -2 hours, that's it.

[0011] The preparation method of the chlorine-free extreme pressure microemulsion cutting fluid comprises the following steps: mixing water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com