Superfine crystalline pure iron preparation method

A technology of ultra-fine grain and pure iron, which is applied in the preparation field of metal rolling technology, can solve problems such as poor welding, affecting material performance stability, and difficulty in large-scale industrial production, and achieves the effect of improving yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0022] This embodiment includes the following specific steps:

[0023] Include the following steps:

[0024] The first step is to select the material to be rolled, keep it at 900°C for 5 hours, and then cool it down to room temperature with the furnace. Remove the scale on the surface after taking out the material to be rolled;

[0025] The thickness of the material to be rolled is 10mm.

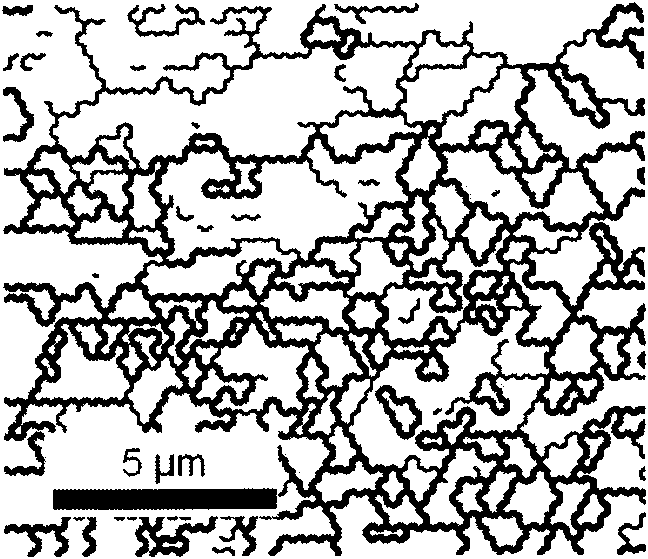

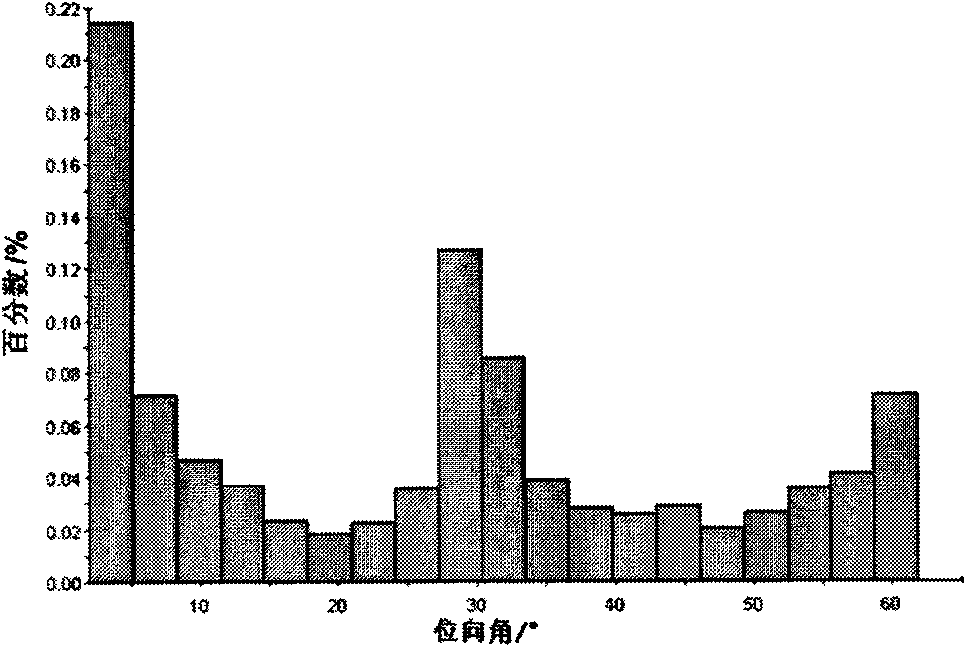

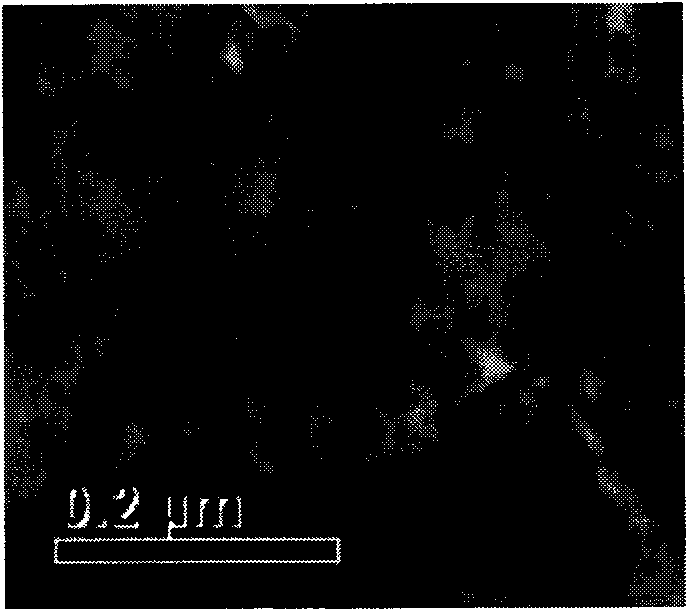

[0026] In the second step, the material to be rolled obtained in the first step is subjected to synchronous rolling at 400° C. to 4 mm; and then asynchronous differential rolling to make a rolled material with a thickness of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com