Feeding guide rail for cross shearing machine

A cross-cutting machine and guide rail technology, which is used in thin material handling, strip winding, transportation and packaging, etc., can solve the problems of complex structure and poor positioning of feeding guide rails, improve production efficiency, prevent deviation, and improve operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

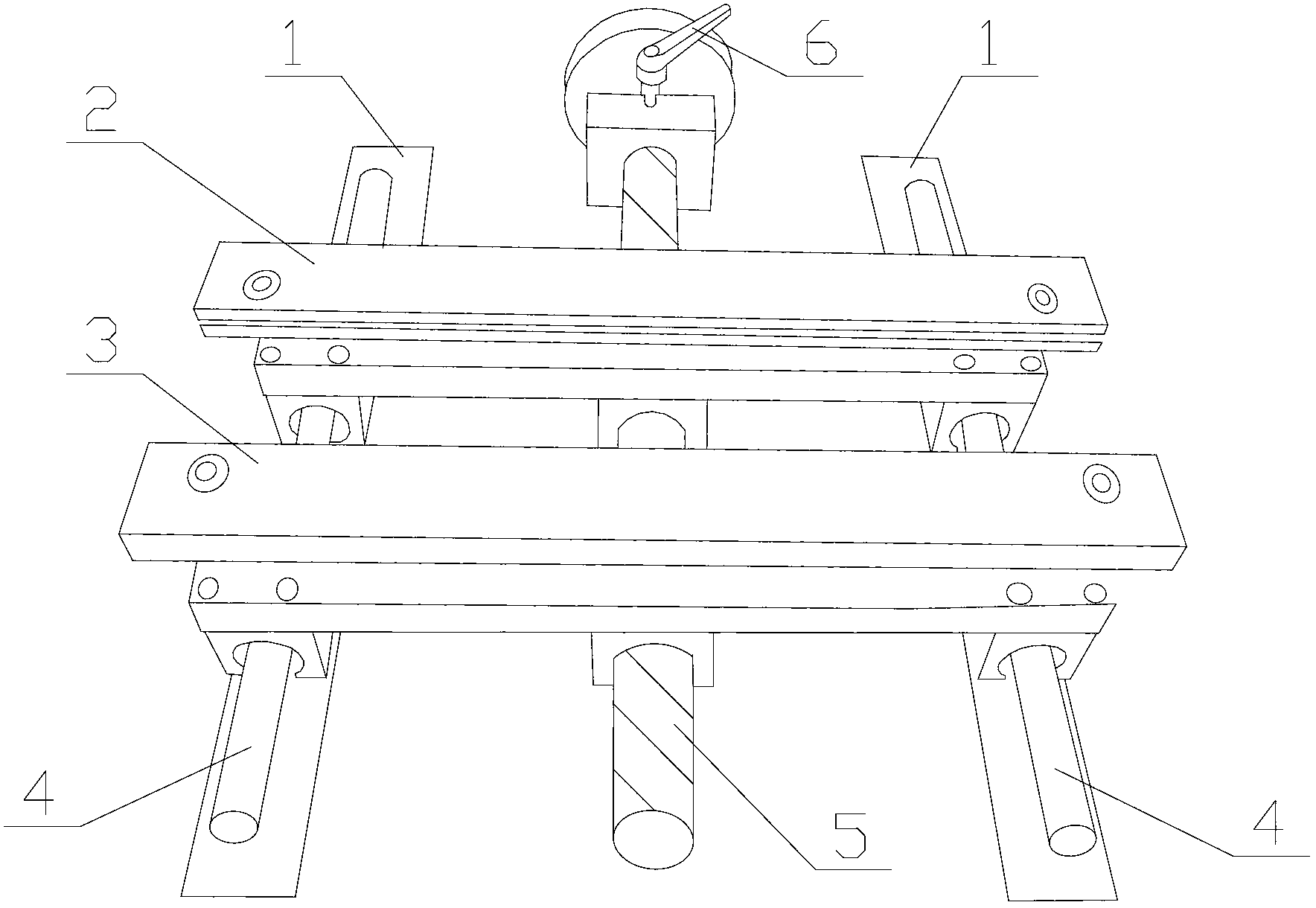

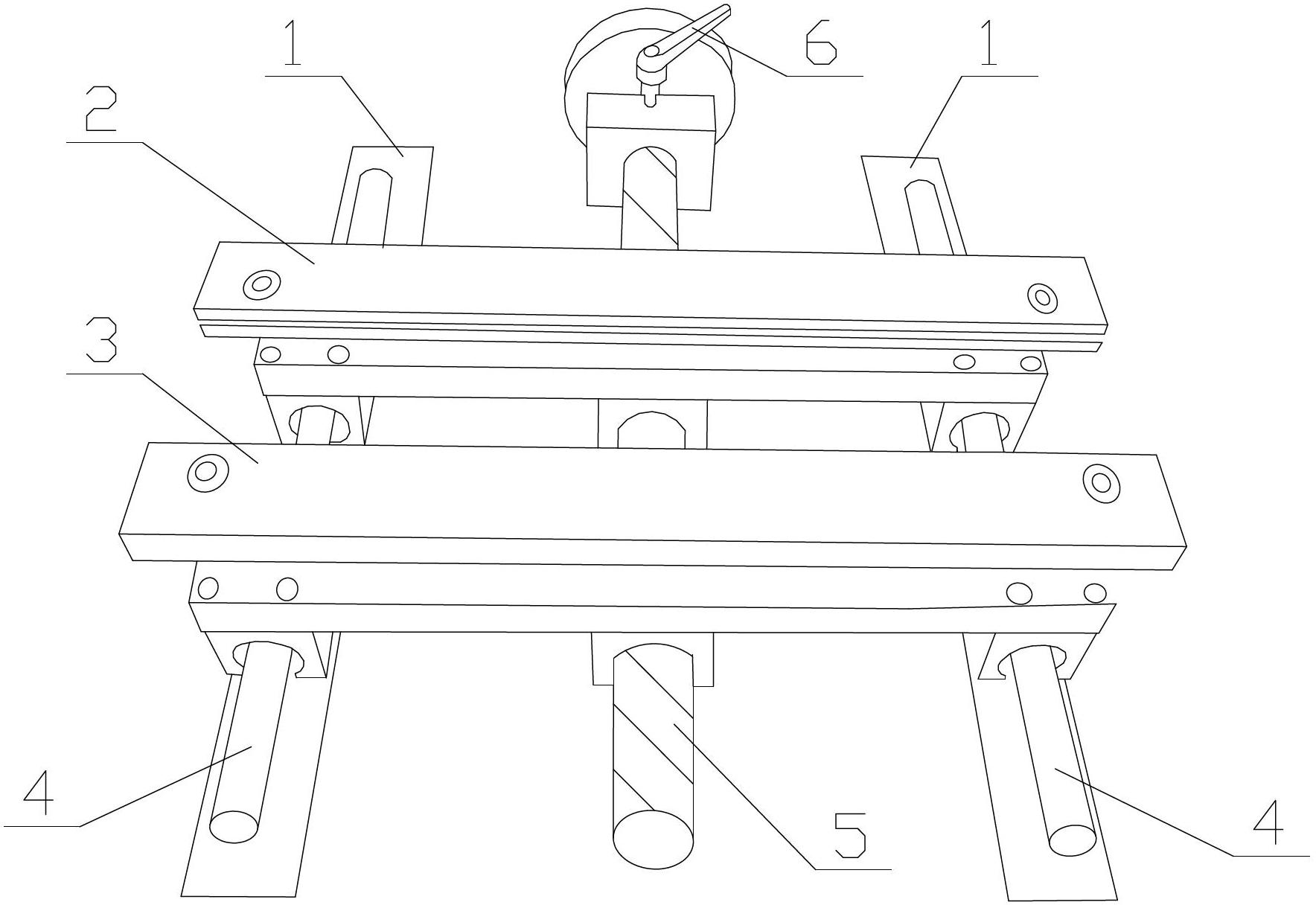

[0016] Please refer to figure 1 as shown, figure 1 It is the structural representation of the feeding guide rail for the cross-shear machine of the present invention;

[0017] In this embodiment, a feeding guide rail for a transverse shearing machine includes a base, on which a bracket 1 and a screw 5 are fixed by bolts, and a shaft 4 is arranged on the bracket 1, and the shaft 4 passes through The sliding blocks arranged at the lower ends of the left guide rail 2 and the right guide rail 3 are slidably connected with the sliding blocks. The inner sides of the left guide rail 2 and the right guide rail 3 are provided with guide wheels, and the lower end of the left guide rail 2 is provided with a nut a. The nut a matches the screw thread at one end of the screw rod 5, and the lower end of the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com