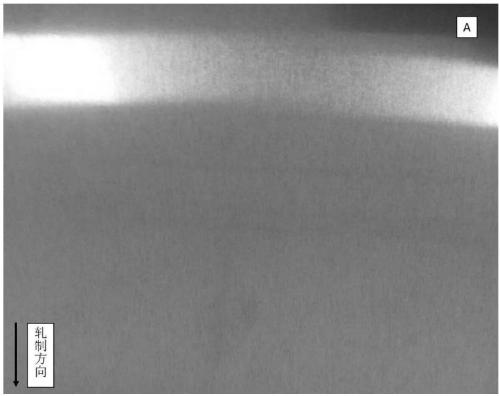

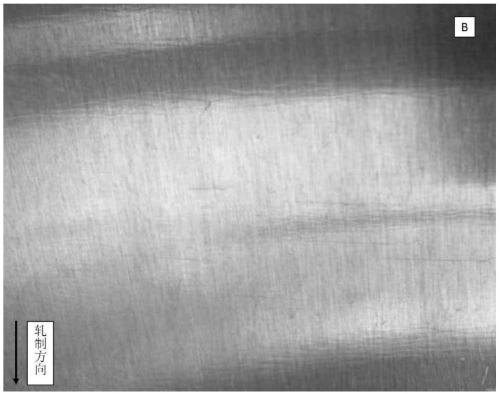

Preparation technology for removing cross grain from surface of 5xxx aluminum alloy sheet

An aluminum alloy sheet and preparation process technology, applied in the field of aluminum alloys, can solve the problems affecting the surface quality of the sheet, prone to horizontal lines, etc., and achieve the effects of better sheet surface quality, improved surface quality, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

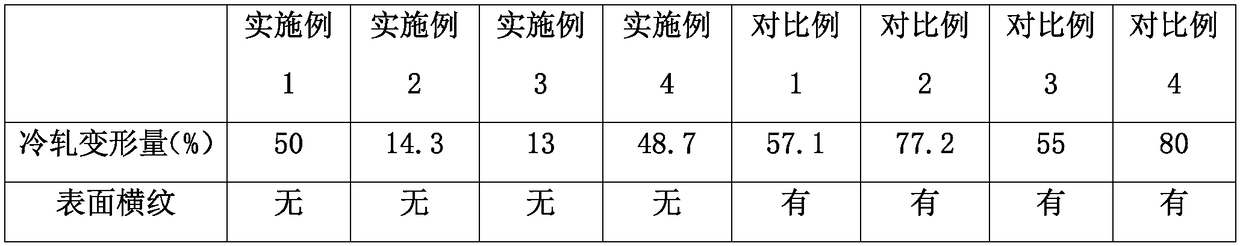

Embodiment 1

[0025] A preparation process for eliminating horizontal lines on the surface of 5-series aluminum alloy plates, taking the finished product 3mm as an example, includes the following steps:

[0026] A. Prepare aluminum alloy raw materials according to the following ratios by weight: Si 0.141%, Fe 0.27%, Cu 0.011%, Mn 0.236%, Mg 2.911%, Cr 0.091%, Zn 0.007%, Ti 0.016%, and other single impurities ≤ 0.05%, the total amount of impurities ≤0.15%, and the balance Al, the prepared aluminum alloy raw materials are added to the melting furnace and mixed evenly, and then smelted into liquid aluminum alloy. The melting temperature is 745°C. ;

[0027] B. Pour the liquid aluminum alloy after stirring and removing slag in step A into a refining furnace for refining for 15 minutes. The refining temperature is 730°C. Stir and remove slag after refining the liquid aluminum alloy. Pass high-purity argon into the melt of the refining furnace and stir the melt, use high-purity argon to remove i...

Embodiment 2

[0030] A preparation process for eliminating horizontal lines on the surface of 5-series aluminum alloy plates, taking the finished product 3mm as an example, includes the following steps:

[0031] A. Prepare aluminum alloy raw materials according to the following ratios by weight: Si 0.141%, Fe 0.27%, Cu 0.011%, Mn 0.236%, Mg 2.911%, Cr 0.091%, Zn 0.007%, Ti 0.016%, and other single impurities ≤ 0.05%, the total amount of impurities ≤0.15%, and the balance Al, the prepared aluminum alloy raw materials are added to the melting furnace and mixed evenly, and then smelted into liquid aluminum alloy. The melting temperature is 745°C. ;

[0032] B. Pour the liquid aluminum alloy after stirring and removing slag in step A into a refining furnace for refining for 15 minutes. The refining temperature is 730°C. Stir and remove slag after refining the liquid aluminum alloy. Pass high-purity argon into the melt of the refining furnace and stir the melt, use high-purity argon to remove i...

Embodiment 3

[0035] A preparation process for eliminating horizontal lines on the surface of 5-series aluminum alloy plates, taking the finished product 2mm as an example, includes the following steps:

[0036]A. Prepare aluminum alloy raw materials according to the following ratios by weight: Si 0.141%, Fe 0.27%, Cu 0.011%, Mn 0.236%, Mg 2.911%, Cr 0.091%, Zn 0.007%, Ti 0.016%, and other single impurities ≤ 0.05%, the total amount of impurities ≤0.15%, and the balance Al, the prepared aluminum alloy raw materials are added to the melting furnace and mixed evenly, and then smelted into liquid aluminum alloy. The melting temperature is 745°C. ;

[0037] B. Pour the liquid aluminum alloy after stirring and removing slag in step A into a refining furnace for refining for 15 minutes. The refining temperature is 730°C. Stir and remove slag after refining the liquid aluminum alloy. Pass high-purity argon into the melt of the refining furnace and stir the melt, use high-purity argon to remove im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com