Cross plate shearing apparatus

A technology of shearing device and cross shearing plate, applied in measuring device, using stable shearing force to test the strength of materials, instruments, etc., can solve the problems of inability to be very accurate, low precision, and high insulation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

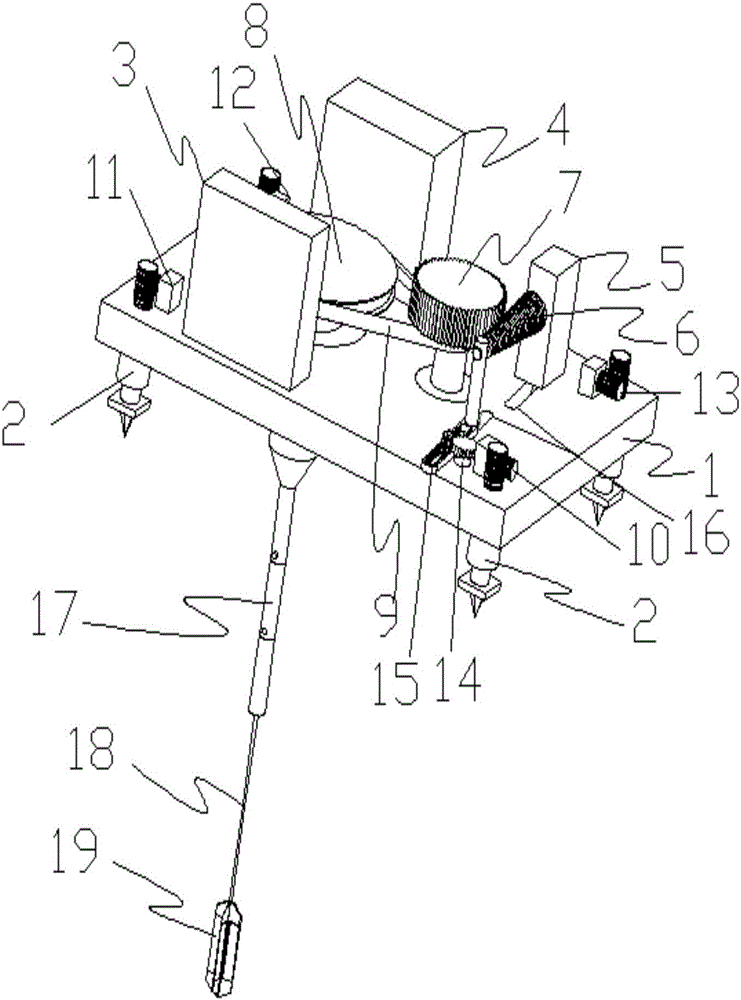

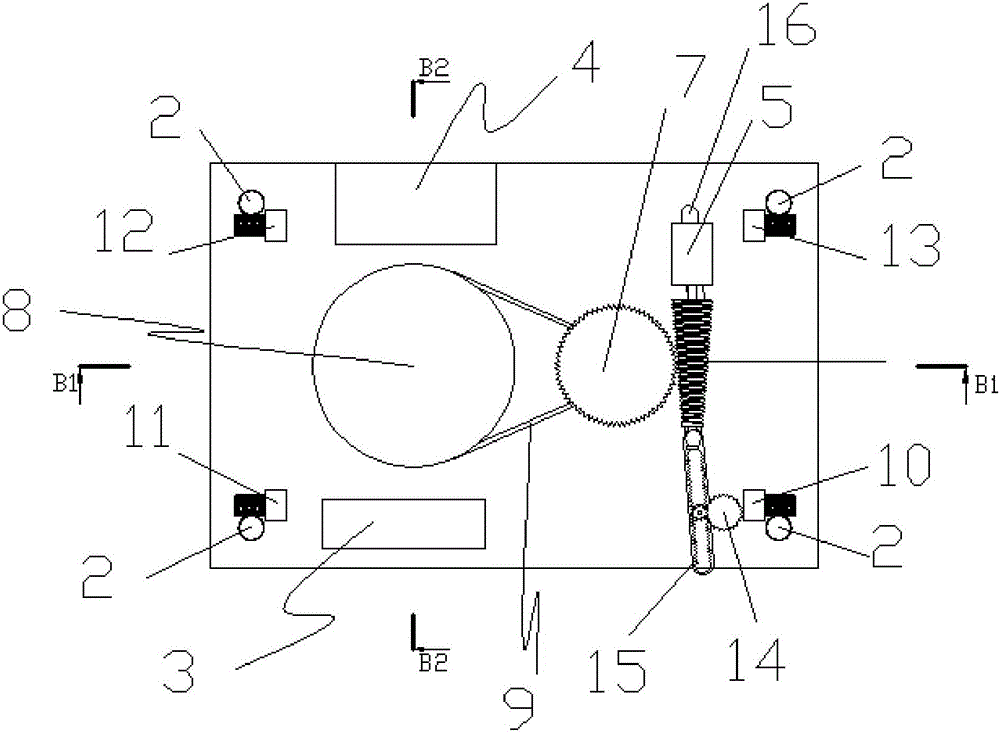

[0070] Such as figure 1 with figure 2 Shown: a cross plate shearing device, including a bottom plate 1 as a loading device platform, support feet 2 around the bottom plate 1, a console 3 and a power supply box 4 on the bottom plate 1.

[0071] The loading device includes a motor 5, a conical wheel 6, a driven wheel structure 7, a runner structure 8, a transmission belt 9 and a stepping motor 5 14. The supporting feet 2 corresponding to the surroundings on the base plate 1 have stepping motor one 10, stepping motor two 11, stepping motor three 12, and stepping motor four 13 to automatically adjust the height of the supporting feet 2 to keep the level.

[0072] The drill rod 17 can be lengthened by connecting many standard long drill rod sections, and the drill rod 17 is connected with the runner structure 8 and the cross plate shear plate axle rod 18 as a force transmission member.

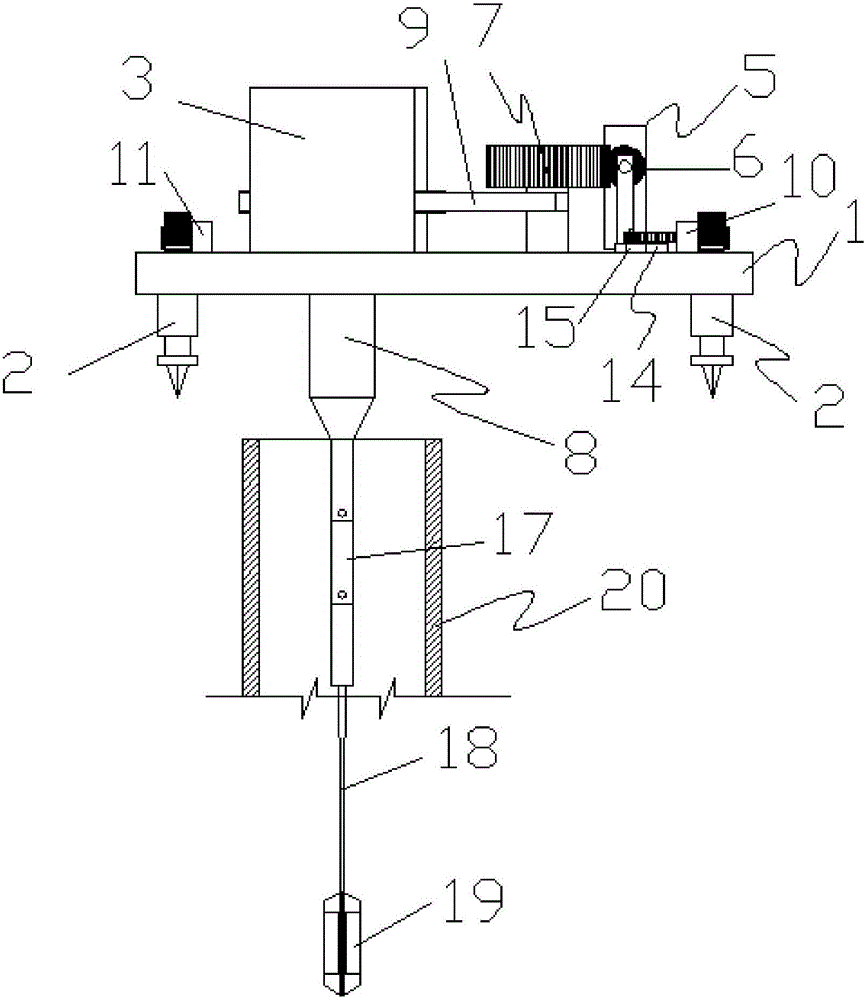

[0073] Such as image 3 As shown, the sleeve 20 is added in the embodiment, and the sleeve ...

Embodiment 2

[0099] In embodiment 2, only the novel cross shear plate device in embodiment 1 is changed, and changes are as follows:

[0100] The new cross shear plate consists of: cross plate shear plate shaft rod 18, fixed blade 53, cross plate 19, one-way bearing 34 and shaft sleeve 55, cross plate shear plate shaft rod 18 is connected with the drill pipe, as Figure 6 shown. A fixed vane 53 is installed on the cross plate shear plate shaft 18, and a one-way bearing is placed between the fixed vane 53 and the cross plate shear plate shaft 18, that is, the top cross plate correction plate 35 of the shaft bar and the cross plate correction plate 35 at the bottom of the shaft bar. A one-way bearing is also used between the plate 36 and the shaft 18 . Such as Figure 15 with Figure 41 As shown, the cross plate shear plate shaft rod 18 is inserted in the shaft sleeve 55 of the cross plate 19, as Figure 15 , Figure 18 with Figure 19 As shown, three one-way bearings 34 are equidistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com