Feeding guiderails of cross cut shear and with magnetic force proximity switches

A technology of proximity switch and cross-cutting machine, which is used in feeding devices, metal processing equipment, manufacturing tools, etc., can solve problems such as failure to meet product accuracy requirements, complex feed rail structure, inconsistent product dimensions, etc. The effect of improving production efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

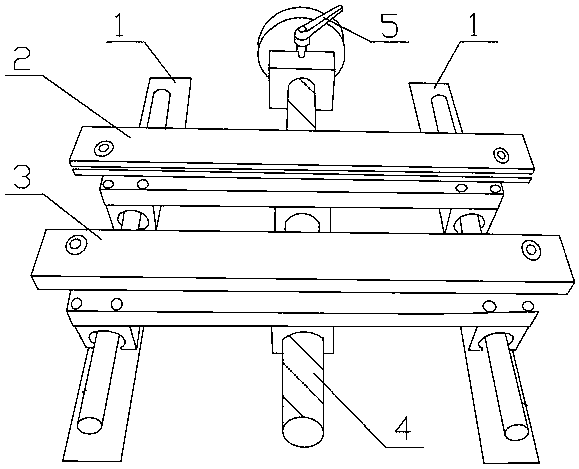

[0010] see figure 1 , the present invention relates to a feeding guide rail of a cross-shear machine with a magnetic proximity switch, comprising a base on which a bracket 1 is fixed by bolts, and the bracket 1 is provided with a left guide rail 2 and a right guide rail 3, The inner sides of the left guide rail 2 and the right guide rail 3 are provided with guide wheels, and the left guide rail 2 and the right guide rail 3 slide left and right on the support 1 through the guide wheels, and a screw rod 4 is provided at the bottom of the left guide rail 2 and the right guide rail 3 , the screw rod 4 is vertically arranged with the left guide rail 2 and the right guide rail 3, the top of the screw rod 4 is screwed with the bottom of the left guide rail 2 and the right guide rail 3 through a nut, and one end of the screw rod 4 is also fixed with the handle 5, and the handle 5 is used for Rotate screw 4.

[0011] When working, by turning the handle 5, the screw rod 4 is driven to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com