Gas cleaning type garbage can

A technology of gas cleaning and trash cans, which is applied in the field of trash cans, can solve the problems of attracting mosquitoes, polluting the environment, human health, volatile odor, etc., to achieve the effects of ensuring cleanliness, reducing the growth of bacteria, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in combination with specific embodiments and accompanying drawings.

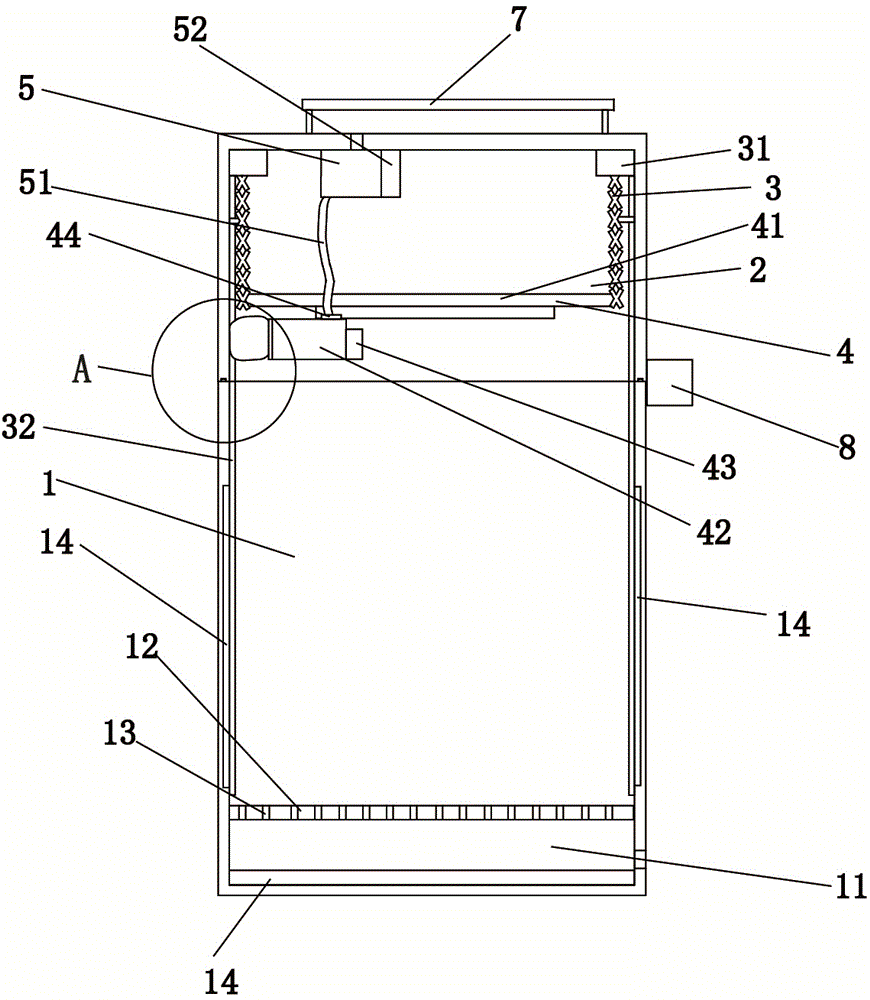

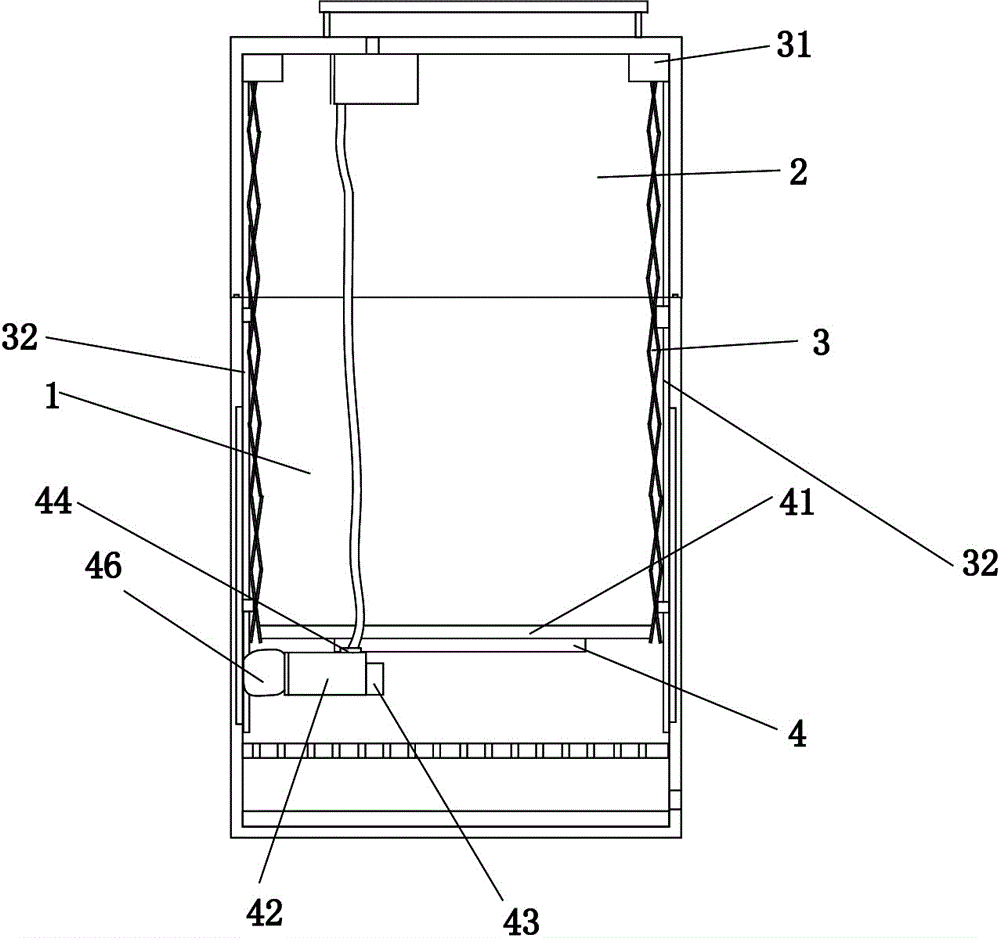

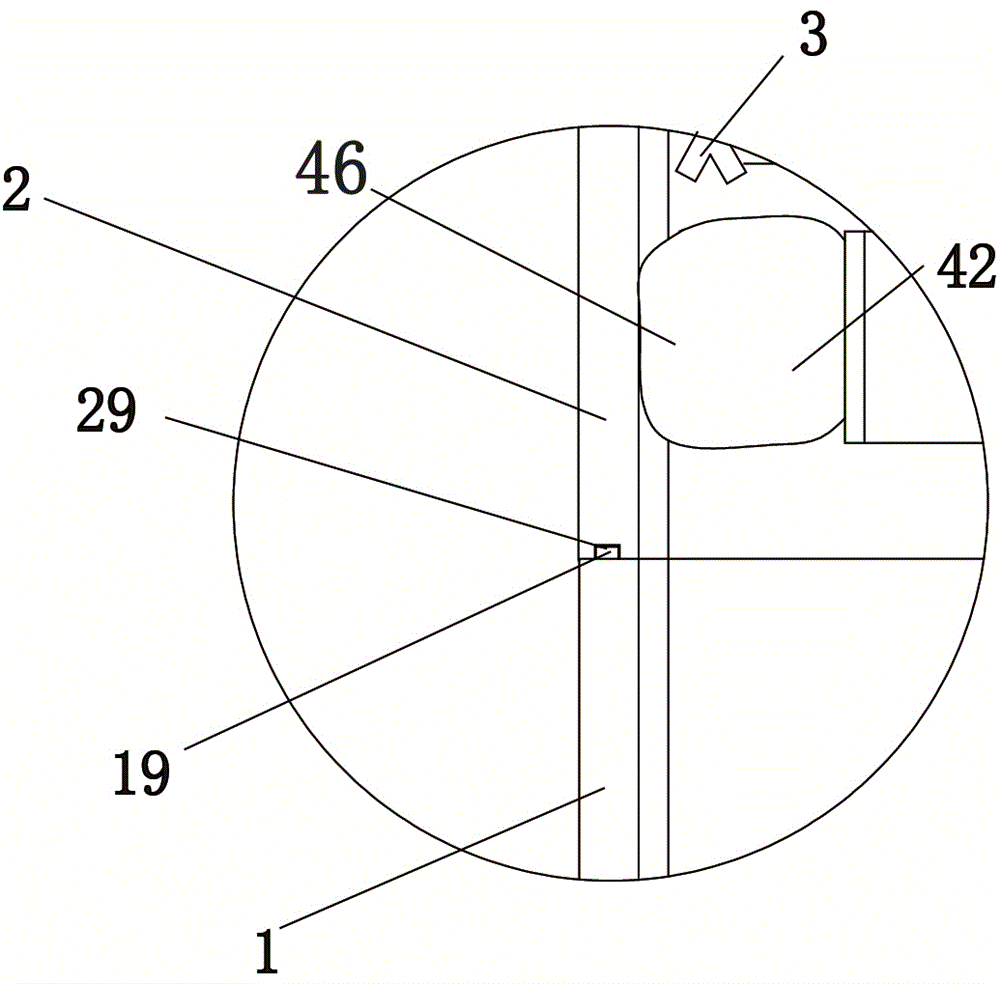

[0016] Such as figure 1 , figure 2 , image 3 As shown, a gas-cleaning trash can includes a barrel body 1 and a barrel cover 2, the barrel body 1 and the barrel cover 2 are connected by an electric rotating shaft 8, and the barrel body 1 is provided with a sealing strip 19. The barrel cover 2 is provided with a sealing groove 29 matching with the sealing strip 19 . An organic box 3 and a water tank 5 are arranged in the barrel cover 2, a motor is arranged in the box 3, and several cross-shear slides are arranged on the inside wall of the barrel body 1 and the barrel cover 2 32. A cross-shear hanger 3 is moved on the cross-shear slideway 32, and the top of the cross-shear hanger 3 is connected to a motor, and the cross-shear hanger 3 is provided with a placement plate 4. Said placing plate 4 is provided with an annular slideway 41, sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com