A transformer iron core automatic lamination production device

A transformer core and production device technology, which is applied in the field of transformer manufacturing, can solve the problems that cannot meet the requirements of automatic positioning and transmission, the width and step of each level of guide rail, frequent boring and repetitive actions, unstable product quality, etc., and achieve compact structure , high degree of automation and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

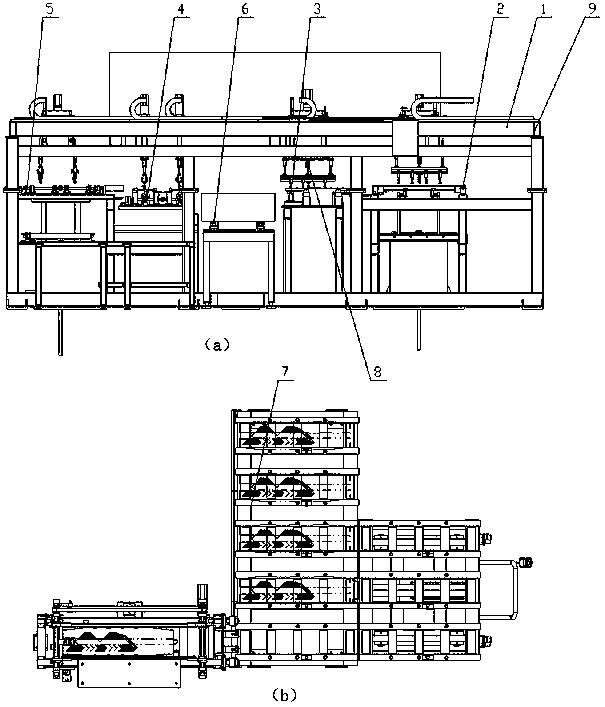

[0032] At present, there are very few equipments for stacking Japanese-type iron cores. Even if there are similar products, most of the stacked iron cores have process holes or rectangular silicon steel sheets, which cannot meet the automatic positioning transmission and automatic adjustment of the width and step of each level of guide rail. requirements. In order to solve the above problems, the present invention provides Figure 1-4 The shown automatic stacking production device for transformer cores can meet the requirements of automatic positioning and transmission of sheet materials in the stacking process only relying on the accuracy of the equipment itself, and can automatically adjust the width of each level of guide rail and the step of the stacking process. Intake.

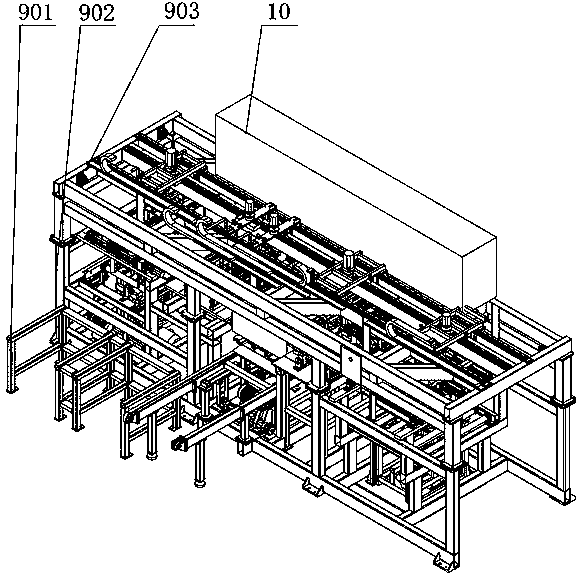

[0033] A transformer iron core automatic stacking production device, at least including a lamination device 8, a three-column slicing device 2, a three-column pre-positioning device 3, a yoke post pre-p...

Embodiment 2

[0049] Based on the above embodiments, in this embodiment, the other auxiliary devices 1 include at least a pneumatic system, a centralized lubrication system and an electric control device; the electric control device and the three-column slicer 2, The three-column pre-positioning device 3, the yoke-column pre-positioning device 4, the yoke-column slicing device 5, the finished product output device 6, the stacking table 7, the stacking device 8, the pneumatic system and the centralized lubricating system are respectively electrically connected.

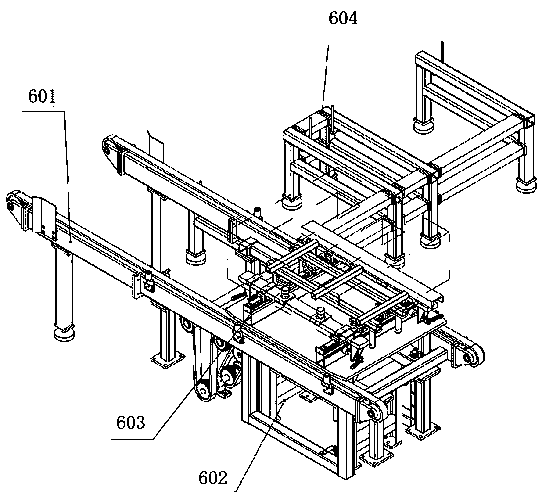

[0050] The finished product output device 6 includes an iron core transmission device 601, a lifting device 602, a stacking platform 603 and a transition bracket 604; the transition bracket 604 is arranged on one side of the iron core transmission device 601, and the lifting device 602 is located on the core In the transmission device 601 , the stacking platform 603 is placed on the lifting device 602 , and the lower surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com