Cross shearing receiving platform for silicon steel sheets

A technology of material receiving platform and cross-cutting line, which is applied in the field of material receiving platform of silicon steel sheet cross-cutting line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

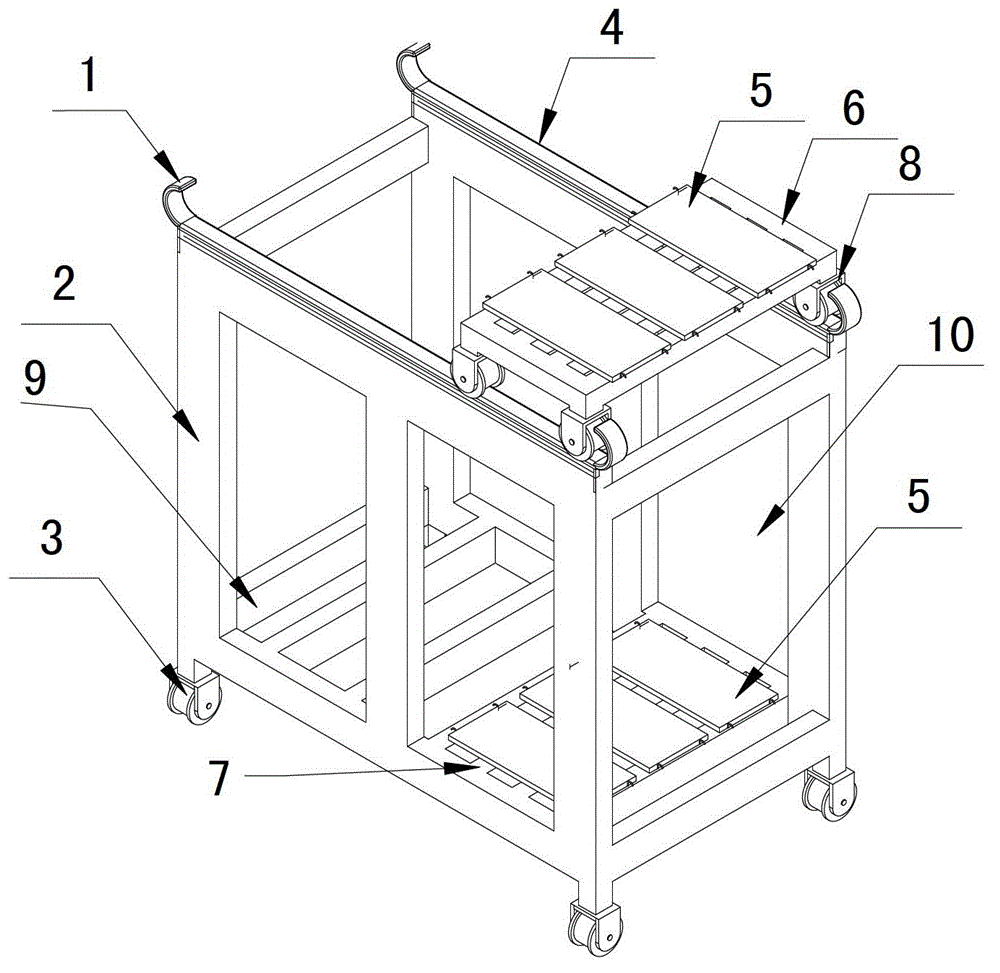

[0011] Attached below figure 1 The present invention is further described in detail.

[0012] figure 1 It is a structural schematic diagram of the material receiving platform of the silicon steel sheet cross-cutting line, including the frame 2, the material receiving plate 5, the crosspiece 7, the material receiving trolley 6, the stop ring 1, the wheel 3, and the track 4.

[0013] The material receiving platform of the silicon steel sheet cross-cutting line includes a vehicle frame 2 and a material receiving plate 5. The vehicle frame 2 is a quadrilateral frame with wheels 3 at the bottom, and the quadrilateral frame is vertically divided into a left half 9 and a right side from the middle. One half 10, on the top surface and the bottom surface of the right half 10, there are three parallel receiving plates 5, and the parallel direction of the three parallel receiving plates 5 is consistent with the rolling direction of the wheel 3, wherein the bottom receiving plate 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com