Micro-texture surface coating self-lubricating cross-shear cutter embedded with solid lubricants

A technology of solid lubricants and surface coatings, applied in the direction of cutting tools, shearing devices, metal processing machinery parts, etc. for shearing machines, can solve human health and environmental hazards, increase the structural complexity of processing equipment and hardware Cost input and other issues to achieve the effect of increasing service life, improving the scope of use and performance, and improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

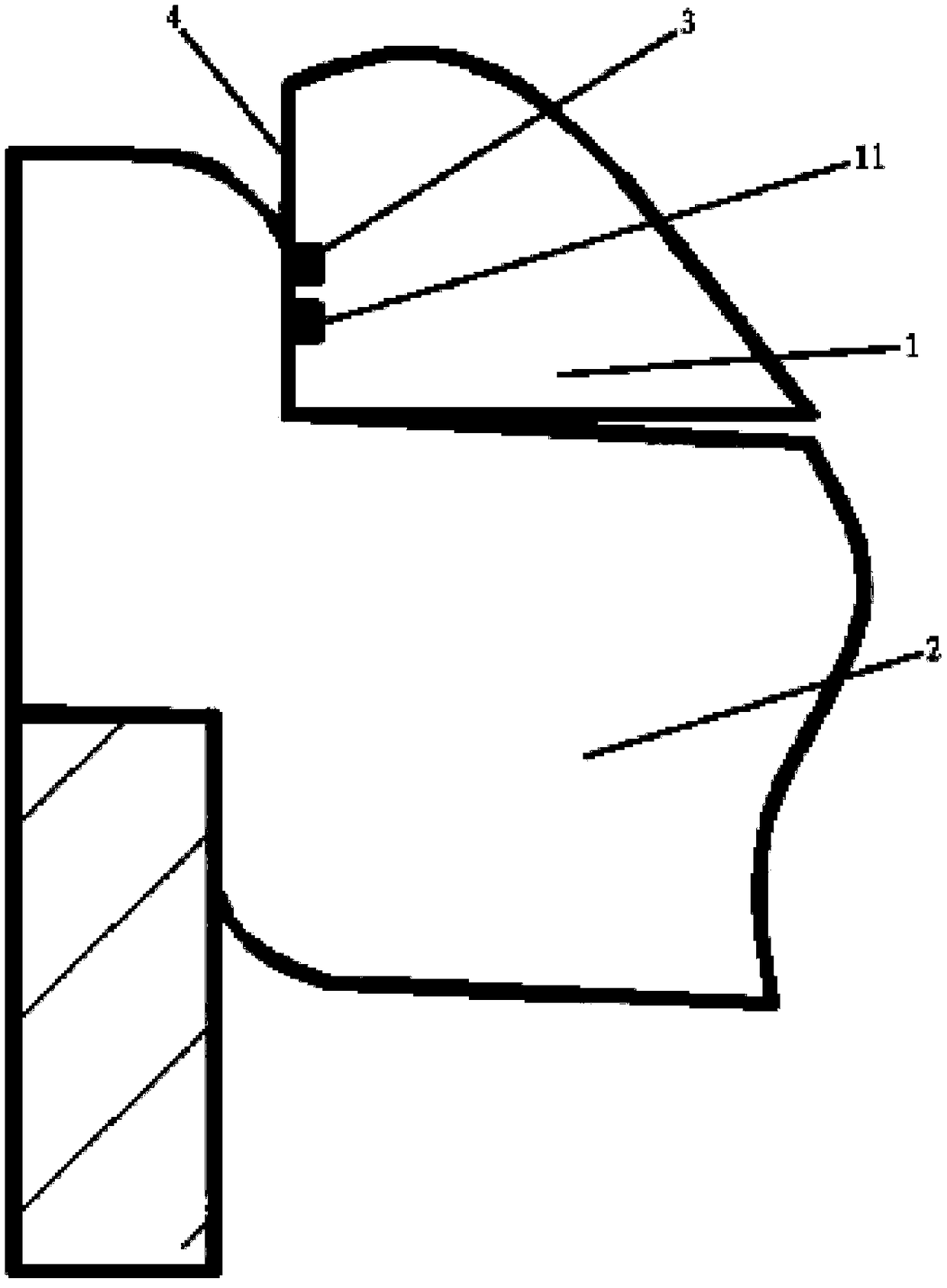

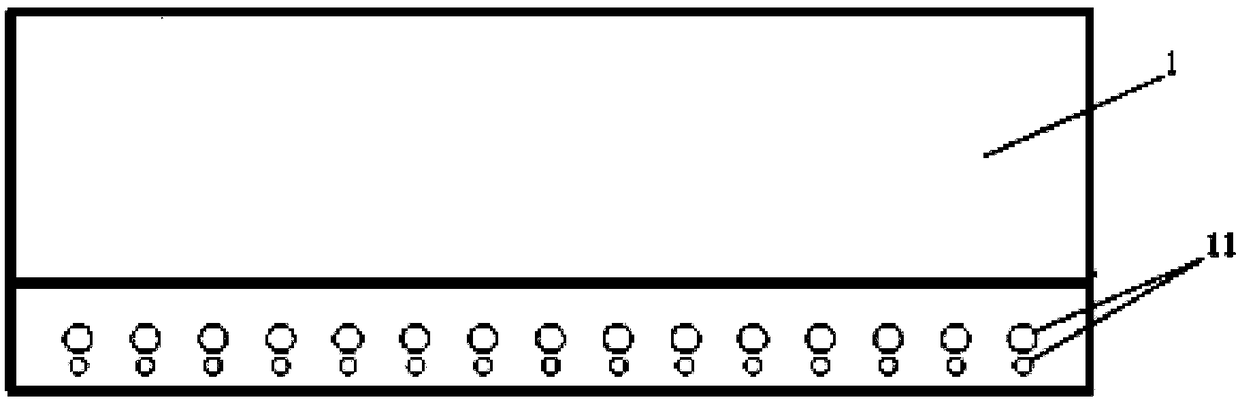

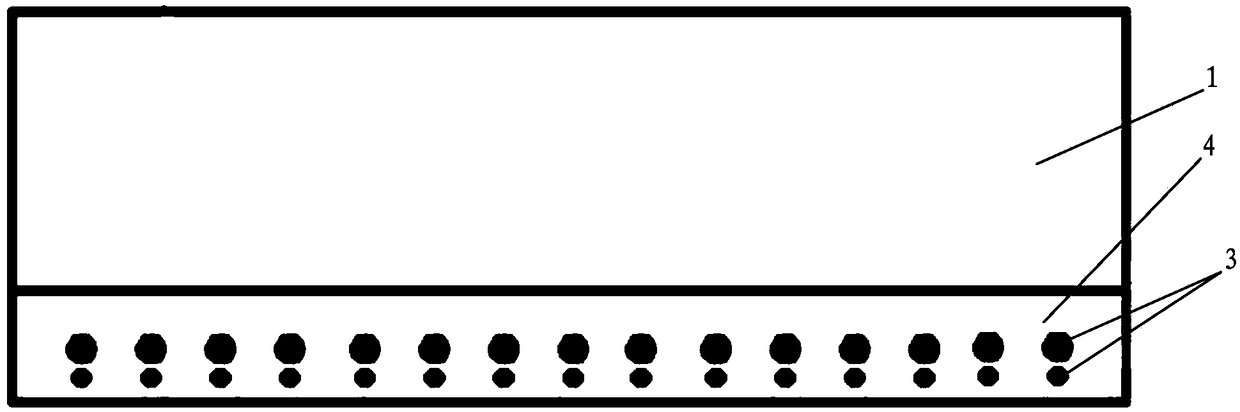

[0023] refer to Figure 1 to Figure 3 , the present embodiment relates to a self-lubricating horizontal scissors, including a tool body 1, a plurality of grooves 11 are provided on the contact surface of the tool body 1 in contact with the metal plate 2, and the grooves 11 are filled with solid lubricant 3 A lubricating coating 4 is provided on the contact surface of the tool body 1 that is in contact with the metal plate 2, and the lubricating coating 4 covers the solid lubricant 3 filled in the groove 11. When the tool body 1 processes the metal plate 2, since the lubricating coating 4 covers the outer surface of the solid lubricant 3 filled in the groove 11, the solid lubricant 3 will not easily come out of the groove 11, And when starting to process, the lubricating coating 4 first lubricates the contact surface between the metal plate 2 and the tool body 1, which can reduce the friction factor and friction force. When the lubricating coating 4 is used up, the solid lubri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com