Amplitude angle adjustable mast drive type cross shear fork lifting mechanism

A technology of lifting mechanism and driving mechanism, which is applied in the direction of lifting frame, lifting device, etc., can solve the problems of large size and heavy weight of lifting mechanism, and achieve large bearing capacity, increased bearing capacity, enhanced stability and anti-overturning ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

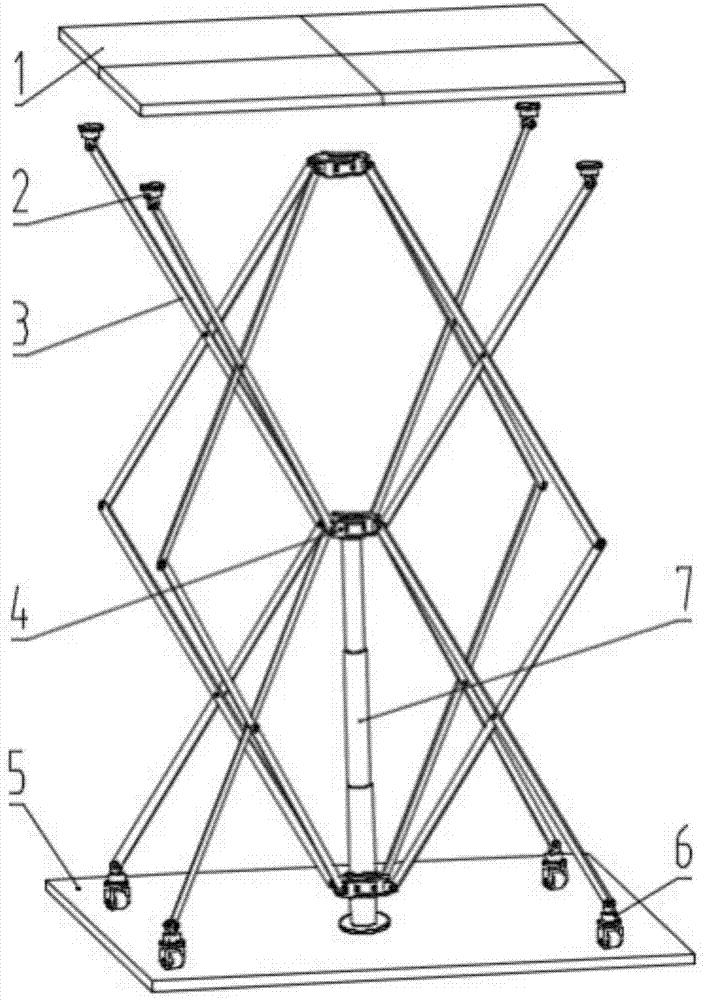

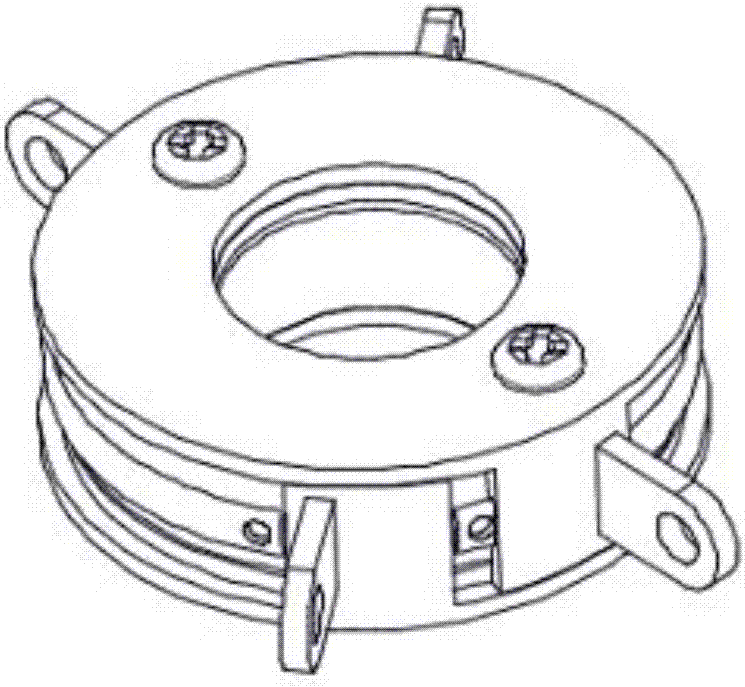

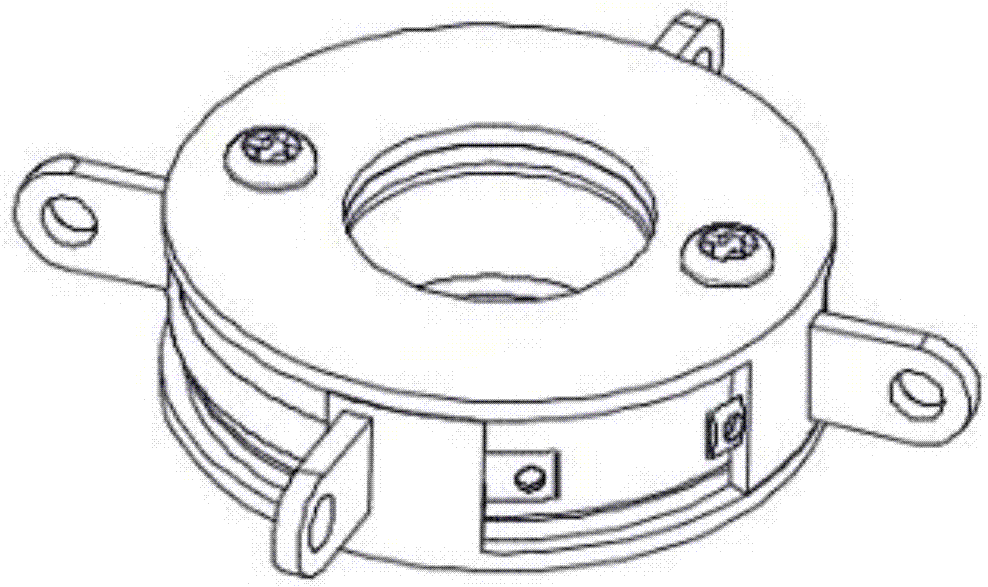

[0033] The present invention will be described in detail below in conjunction with accompanying drawing, as Figure 1-8As shown: the present invention provides a mast-driven cross scissors lifting mechanism with adjustable argument angle, including a cross scissors mechanism 3, a mast drive mechanism 7, an angle adjustment mechanism 4 and a support plate 1; the cross scissors mechanism It includes a scissors module assembled in sequence in multiple layers. The scissors module includes a plurality of connecting rods, and the connecting rods include a plurality of inner connecting rods whose top ends are gathered inwardly and a plurality of outer connecting rods whose top ends are spread out outwardly. The inner connecting rods of the same scissor module correspond to the outer connecting rods one by one, and the corresponding inner connecting rods and outer connecting rods are cross-hinged to form a scissor structure; between two adjacent layers of scissor modules: the lower inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com