Method for improving wearability of wearable high manganese steel by using asymmetrical rolling

A technology of asynchronous rolling and high manganese steel, which is applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of plasticity, toughness decline, production process, complex equipment, etc., and achieve easy plastic processing and good wear resistance , the effect of high impact toughness values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

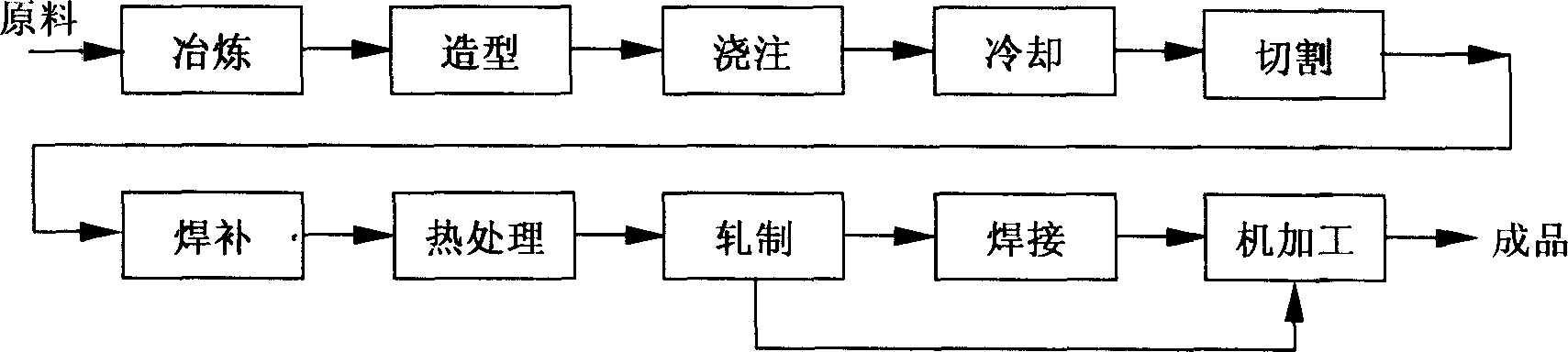

Image

Examples

Embodiment 1

[0025] Embodiment 1: steel for railway turnout

[0026] 1. Smelting: Molten steel is smelted by oxidation method to make phosphorus and other oxides react to form stable compounds, which are removed with slag.

[0027] 2. Modeling: Silica sand or limestone raw sand is used to make water glass sand or clay dry mold sand for molding.

[0028] 3. Pouring: The principle of sequential solidification is adopted, the riser gate is used with spacers, and the inner gate enters the riser tangentially to increase the temperature of the riser molten steel and increase the feeding efficiency of the riser. Adding chilled iron improves the cooling capacity of the mold and controls the solidification speed of the casting.

[0029] 4. Cooling: After the casting is poured and solidified, loosen the box in time, remove the fastening bolts of the sand box and lift away the pressure iron to reduce shrinkage resistance and prevent cracks. The outlet temperature of simple and thin-walled castings ...

Embodiment 2

[0035] Example 2: Steel for ball mill liner

[0036] 1. Smelting: Molten steel is smelted by oxidation method to make phosphorus and other oxides react to form stable compounds, which are removed with slag.

[0037] 2. Modeling: Silica sand or limestone raw sand is used to make water glass sand or clay dry mold sand for molding.

[0038]3. Pouring: The principle of sequential solidification is adopted, the riser gate is used with spacers, and the inner gate enters the riser tangentially to increase the temperature of the riser molten steel and increase the feeding efficiency of the riser. Adding chilled iron improves the cooling capacity of the mold and controls the solidification speed of the casting.

[0039] 4. Cooling: After the casting is poured and solidified, loosen the box in time, remove the fastening bolts of the sand box and lift away the pressure iron to reduce shrinkage resistance and prevent cracks. The outlet temperature of simple and thin-walled castings is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com