An Assembled Integral Frame Structure Housing System

A frame structure, integral technology, applied in the direction of residential buildings, building components, building structures, etc., can solve the problems of increasing construction procedures, long construction period, prolonging construction period, etc., so as to improve the integrity and seismic performance, and solve the Adverse effects, solving the effect of thermal insulation and sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

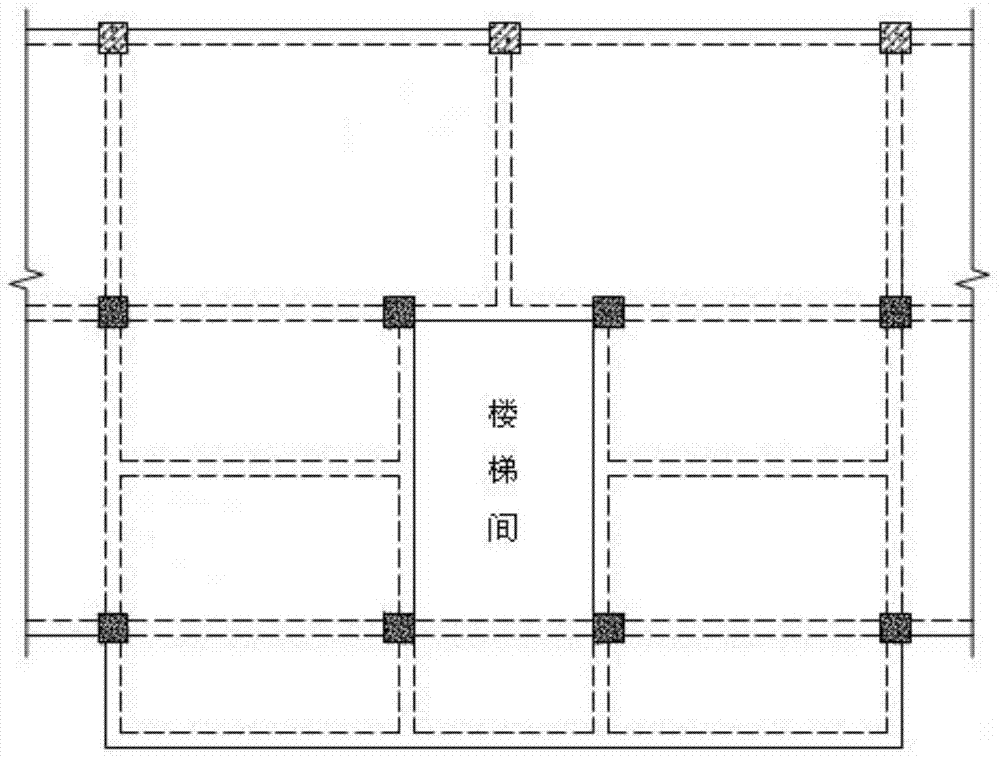

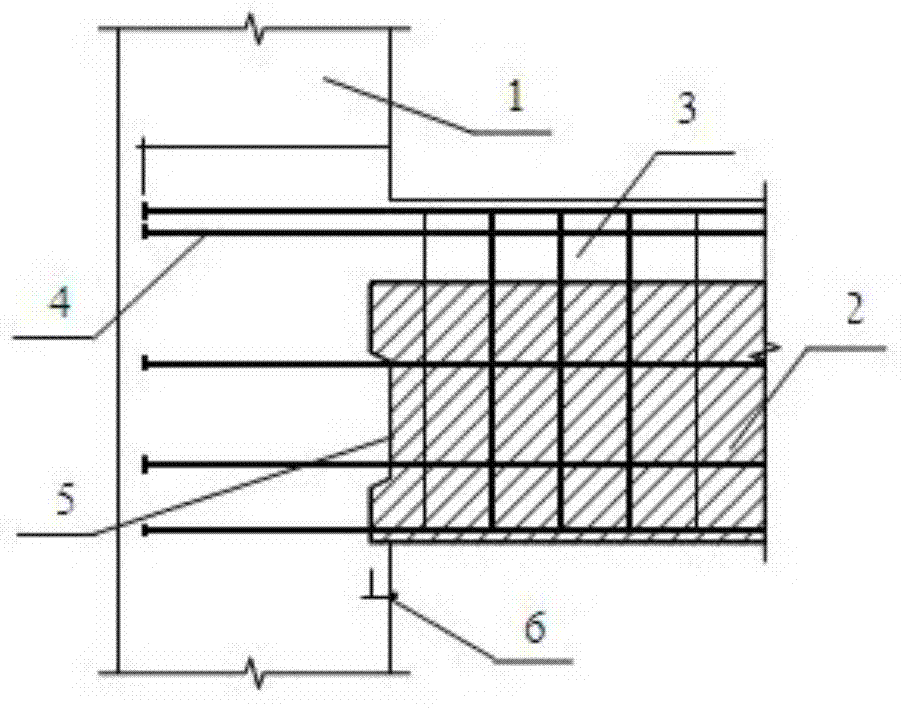

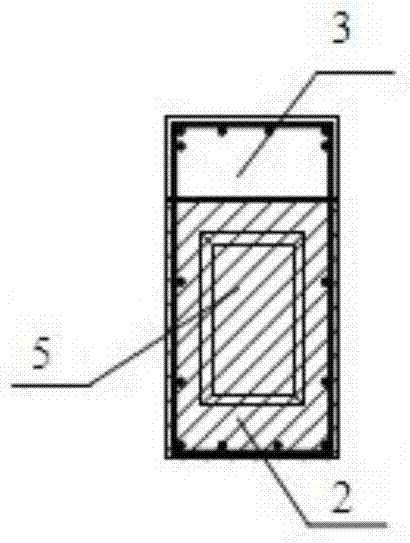

[0039] Principle and benefit of the present invention are as Figure 1-Figure 11 As shown, the disclosed assembled monolithic frame structure residential system includes a load-bearing frame of cast-in-place columns and laminated beams, a separated shock-absorbing prefabricated staircase, a prefabricated laminated floor and prefabricated filled interior and exterior wall panels. In the structural system, fully consider the mechanical performance requirements of "connection is completely connected, disconnection is completely disconnected", that is, beam-column joints are cast-in-situ, primary and secondary beam joints are post-cast concrete, precast beams are laid after laying The superimposed layers form a whole, the stairs are fixed at one end and slide at the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com