Rigid-flexible composite structural pavement and cast-in-place method and prefabricating method for manufacturing rigid-flexible composite structural pavement

A rigid-flexible composite and rigid technology, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of not being as good as the average service life, low structural strength, and weak impact fatigue resistance, etc., and improve the road surface The structure is stressed, the ability to resist shear stress damage is improved, and the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described below with reference to the accompanying drawings. Elements and features described in one figure or embodiment of the invention may be combined with elements and features shown in one or more other figures or embodiments. It should be noted that representations and descriptions of components and processes known to those of ordinary skill in the art that are unrelated to the present invention are omitted from the drawings and description for the purpose of clarity.

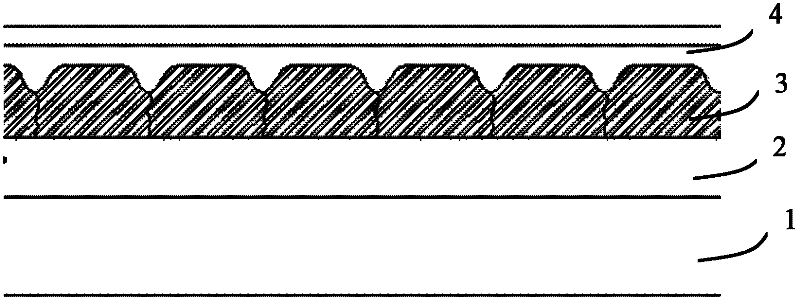

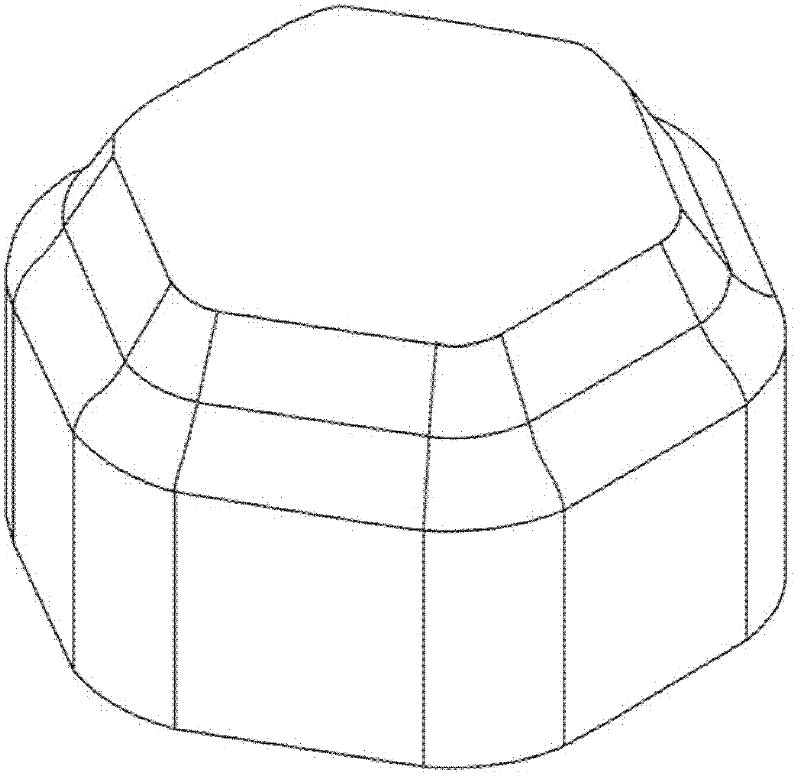

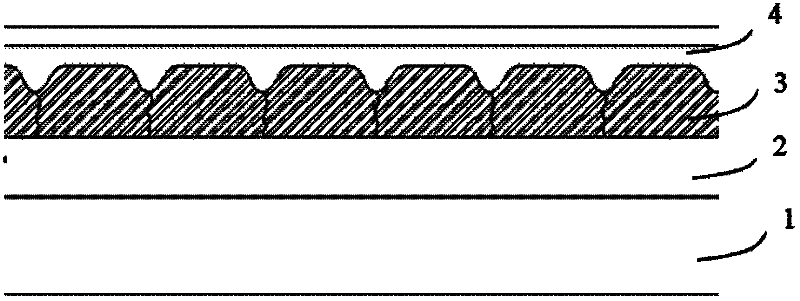

[0031] An embodiment of the present invention provides a rigid-flex composite structure pavement, such as figure 1 As shown in the figure, it includes: a road bed layer, which is a compacted road subgrade; a cushion layer 1, which is composed of lime soil or graded gravel, and is arranged on the road bed layer. The rigid layer 3 is leveled; the base layer 2, the base layer 2 is composed of a cement-stabilized crushed stone base layer or a lime base laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com