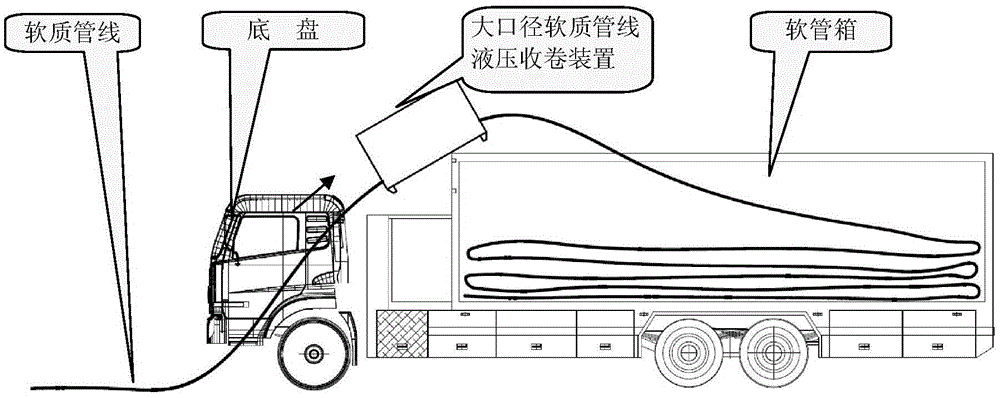

Hydraulic winder for large-caliber soft pipeline

The technology of a flexible pipeline and a winding device is applied in the directions of winding strips, transportation and packaging, thin material processing, etc., which can solve the problems of short service life of the hose, large structural size and weight, and unfavorable installation and use, etc. Achieve the effect of light weight, simple structure and vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described:

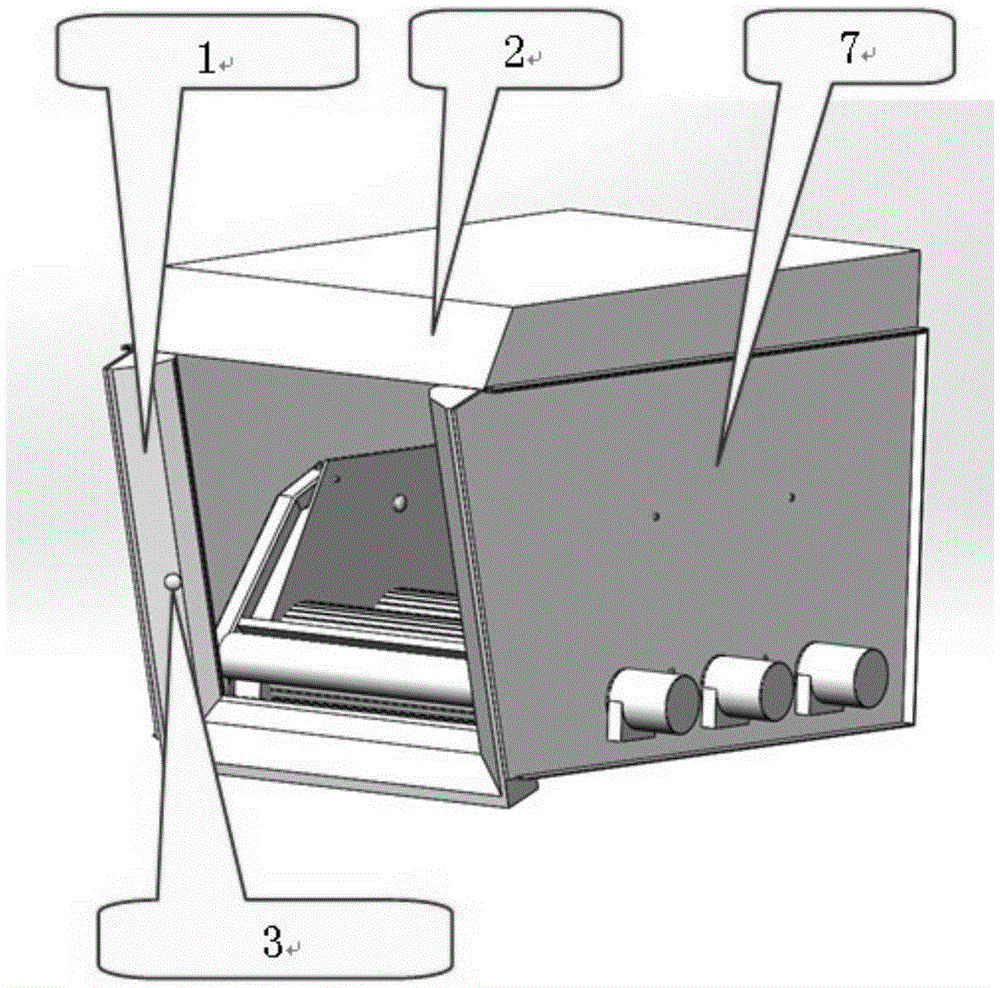

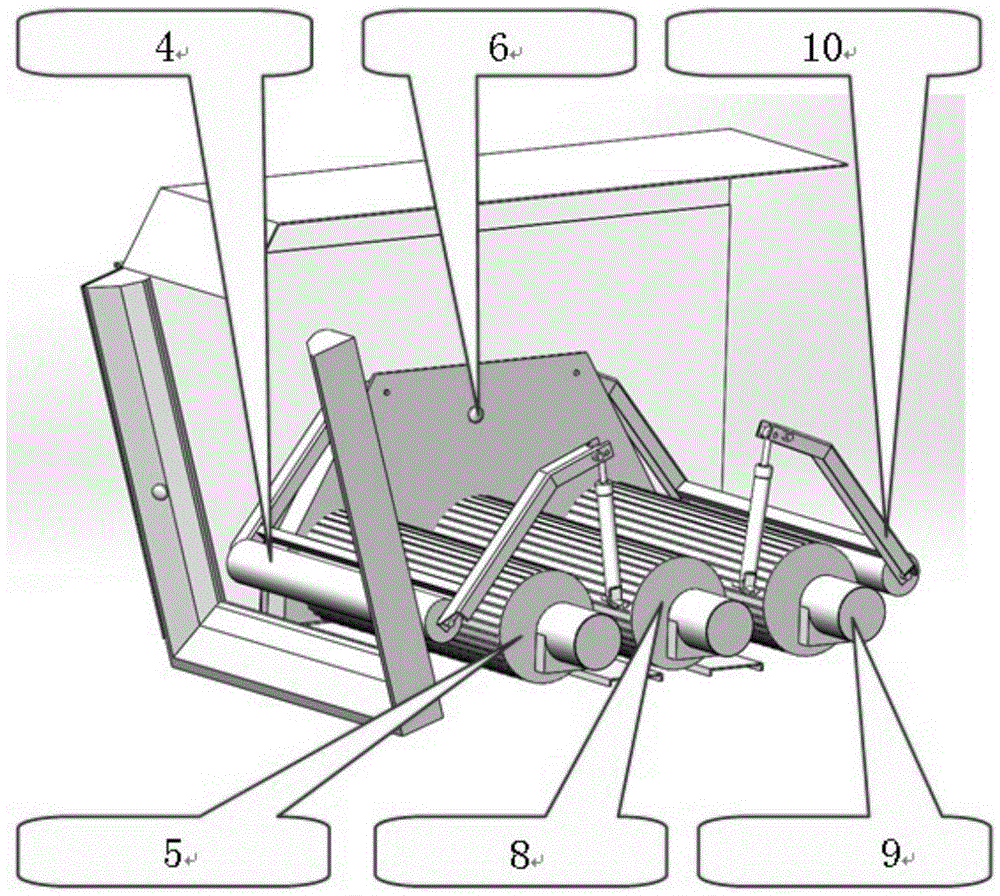

[0029] Such as figure 1 As shown, a large-diameter flexible pipeline hydraulic rewinding device includes a frame 7 and a hose guide frame 1 arranged at the front end of the frame 7, and a second hose guide frame 1 is provided in the middle of the hose guide frame 1 A photoelectric sensor 3, the middle part of the frame 7 is provided with a winding pulley mechanism and a second photoelectric sensor 6, and the rear tension wheel mechanism 10 is arranged at the rear end of the frame 7. When winding, the front tension wheel mechanism 4 and the The rear tensioning wheel mechanism 10 makes the soft pipeline and the pulley of the winding pulley mechanism tightly fit, the hydraulic motor of the winding pulley mechanism drives the pulley to rotate, and the rotation of the winding pulley drives the soft pipeline to move through friction When the first photoelectric sensor 3 detects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com