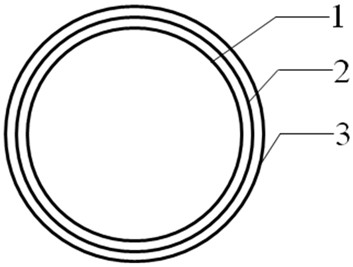

Tubular non-woven fabric and its preparation method

A non-woven fabric and tube-type technology, which is applied in the field of tube-type non-woven fabric and its preparation, to achieve the effect of improving cohesion and binding force and improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) Opening and carding: on the outer surface of the tubular polyester net with a diameter of 25mm, weigh the fibers of the inner web layer, the fibers of the middle web layer and the fibers of the outer web layer according to the mass ratio of 4:3:3 , the fiber of the inner web layer (polyvinyl alcohol fiber, linear density 5dtex, length 20mm), middle fiber web layer fiber (polyester fiber, linear density 6dtex, length 30mm) and outer web layer fiber (polypropylene fiber , with a linear density of 10dtex and a length of 50mm) were respectively opened and carded into a tubular mesh to obtain the inner fiber web layer fiber web, the middle fiber web layer fiber web, and the outer fiber web layer fiber web;

[0052] 2) The first spunlace: use the spunlace machine to perform spunlace on the front and back of the inner fiber web layer fiber web, the middle fiber web layer fiber web and the outer fiber web layer fiber web prepared in step 1) (spunlace suction The negative pre...

Embodiment 2

[0058] 1) Opening and carding: on the outer surface of the tubular polyester mesh with a diameter of 12mm, weigh the fibers of the inner web layer, the fibers of the middle web layer and the fibers of the outer web layer according to the mass ratio of 4:4:2 , the inner web layer fiber (polyacrylonitrile fiber, linear density 4dtex, length 40mm), middle web layer fiber (polypropylene fiber, linear density 6dtex, length 30mm) and outer web layer fiber (polyester fiber , with a linear density of 3dtex and a length of 40mm) were respectively opened and carded into a tubular mesh to obtain the inner fiber mesh layer fiber mesh, the middle fiber mesh layer fiber mesh, and the outer fiber mesh layer fiber mesh;

[0059] 2) The first spunlace: use the spunlace machine to perform spunlace on the front and back of the inner fiber web layer fiber web, the middle fiber web layer fiber web and the outer fiber web layer fiber web prepared in step 1) (spunlace suction The negative pressure i...

Embodiment 3

[0065] 1) Opening and carding: on the outer surface of the tubular polyester mesh with a diameter of 5mm, weigh the fibers of the inner web layer, the fibers of the middle web layer and the fibers of the outer web layer according to the mass ratio of 5:4:1 , the inner web layer fiber (polyester superfine fiber, linear density 0.3dtex, length 10mm), middle web layer fiber (polyester fiber, linear density 10dtex, length 40mm) and outer web layer fiber (polypropylene fiber, the linear density is 12dtex, and the length is 40mm) are respectively opened and carded into a tubular network, and the inner fiber network layer fiber network, the middle fiber network layer fiber network, and the outer fiber network layer fiber network are respectively obtained;

[0066] 2) The first spunlace: use the spunlace machine to perform spunlace on the front and back of the inner fiber web layer fiber web, the middle fiber web layer fiber web and the outer fiber web layer fiber web prepared in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com