Steel wire framework heat preservation building block

A technology of steel wire skeleton and thermal insulation blocks, which can be applied to building materials and other directions, and can solve the problems of small tie force and poor earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

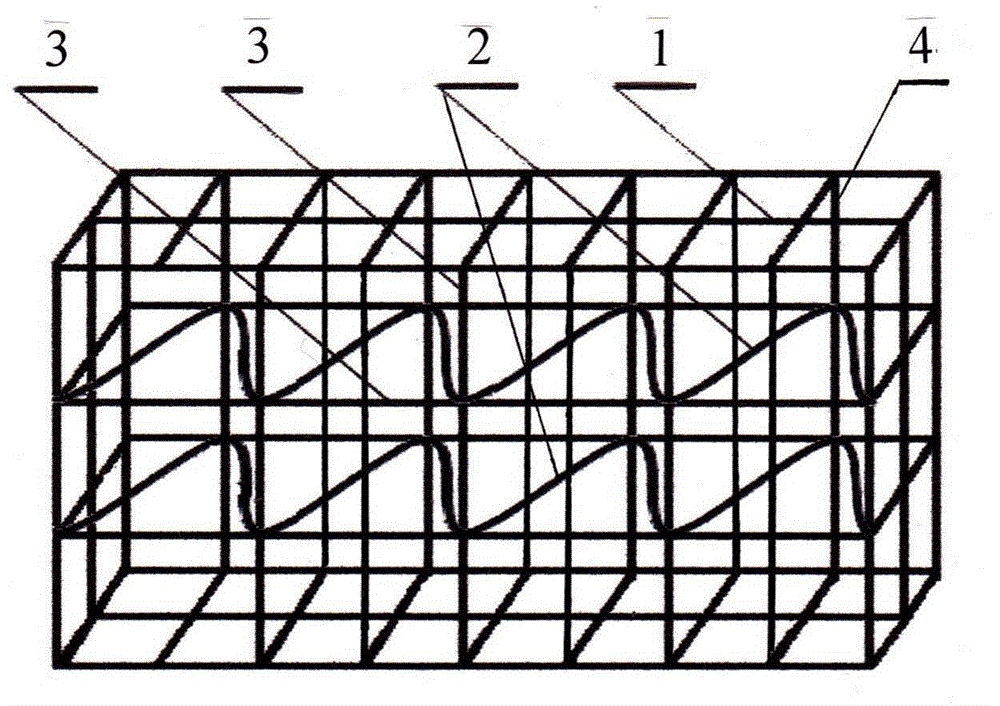

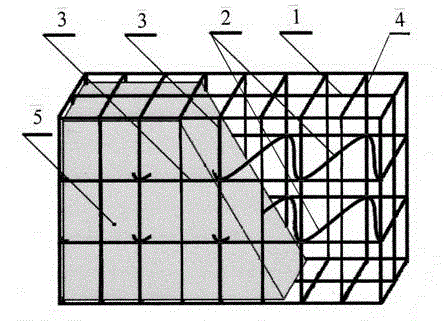

[0012] see Figure 1~2 1. The steel wire skeleton of the steel wire skeleton thermal insulation block is composed of a rectangular steel wire mesh frame 1 and a "zigzag" shaped abdominal bar 2 arranged between the two facades of the rectangular steel wire mesh frame. The steel wires 3 and 4 on the two facades of the rectangular steel wire mesh frame are located 1 cm outside the block body 5 . The other four peripheral steel wires of the rectangular steel wire mesh frame can be on the same surface as the block body periphery, or can protrude outside the block body like the facade steel wires. What this embodiment provides is the structural form that all protrudes outside the building block. The material of the block is to use cement as the cementing material, fly ash, perlite, vermiculite, ceramsite and other lightweight thermal insulation materials as the aggregate, after adding water to mix and stir evenly, pour it into the box with welded rectangular steel wire mesh frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com