Construction method for deep foundation pit of elevator shaft

A construction method and elevator shaft technology, which are applied in basic structure engineering, excavation, vertical pipelines, etc., can solve problems such as cold joints in construction, difficulties in cushion construction, and undrained water accumulated on the bottom plate, so as to improve the engineering quality. Quality, water seepage risk reduction, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment, the present invention is further described:

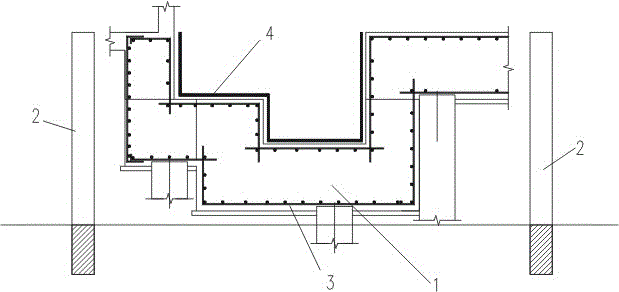

[0028] Such as figure 1 The elevator shaft deep foundation pit construction method shown, the method includes the following steps:

[0029] Firstly, before the construction, mark and delineate the construction area at the construction position of the deep foundation pit 1 of the elevator shaft, and reserve a space of 15-30 meters on both sides of the construction area for the construction of the auxiliary dewatering pit 2;

[0030] The auxiliary dewatering pit 2 is a pair of vertical deep pits of the same specification and depth, which are symmetrically arranged on both sides of the construction position of the deep foundation pit 1 of the elevator shaft, and the distance from the deep foundation pit 1 of the elevator shaft is greater than 5m. The deepest part of pit 1 is 1-2m deeper; during the construction of auxiliary dewatering pit 2, the water in the pit is continuously pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com