Garbage compression processing station and garbage processing method

A technology of garbage compression and treatment station, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve the problems of low degree of automation, labor-intensive, large exhaust gas inhalation, etc., and achieves high intelligence strength, reasonable overall design, and convenient management. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further illustrated by the following examples:

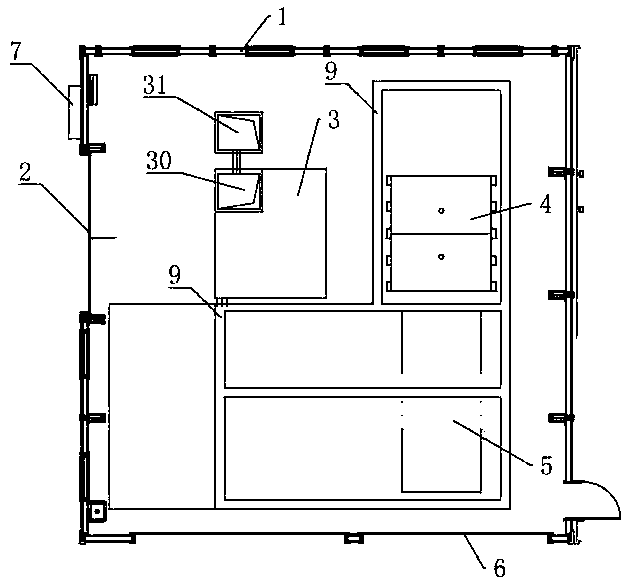

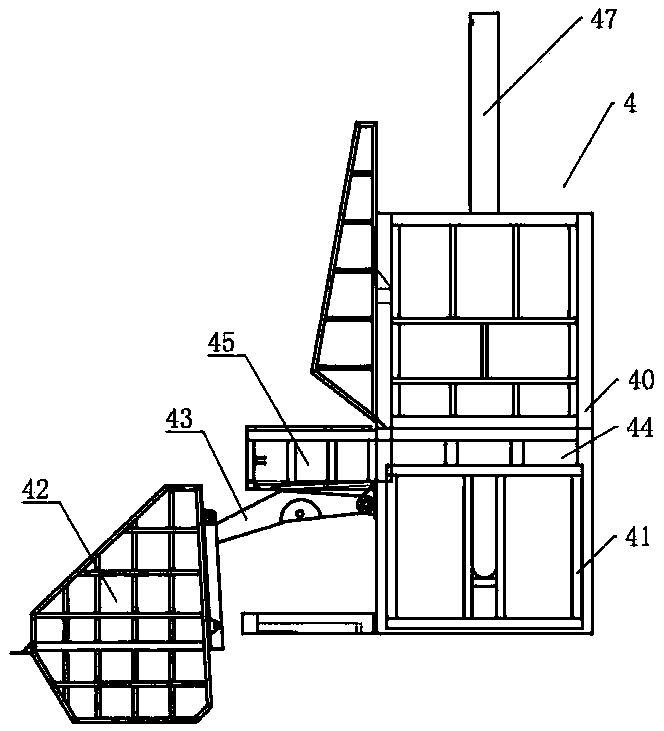

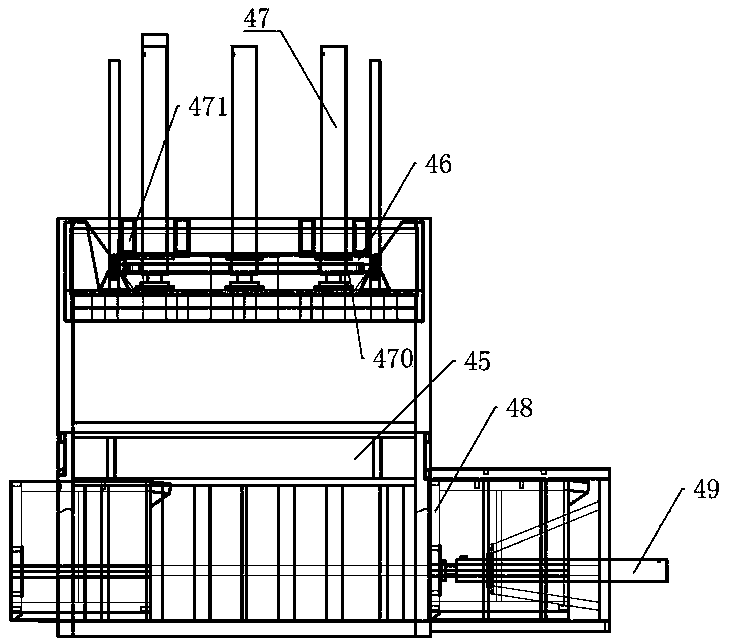

[0014] refer to figure 1 , a garbage compression treatment station, comprising an external wall 1, a feed door 2 is provided on one side of the wall 1, a pit 3 is provided on the inner side of the feed gate 2, and a garbage compression device 4 is provided on one side of the pit 3 . The bottom of the pit 3 is inclined to one side, and a settling well 30 is provided at the lowest point thereof, and the settling well 30 is connected to a water collection well 31 provided outside the pit 3 . In the garbage compression device 4, a garbage exchange position 5 is provided on the side of the garbage outlet, and a discharge door 6 is provided on one side wall 1 of the garbage exchange position 5, and a drain is provided on the peripheral bottom surface of the garbage compression device 4 and the garbage exchange position 5. Groove9. A controller 7 provided on the outside of body of wall 1 .

[0015] r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com