Abrasion-resistant concrete terrazzo floor construction method

A construction method and concrete surface technology, which is applied to machine tools, grinders, floors, etc., which are suitable for grinding workpiece planes, can solve the problems of filth, filth, and environmental pollution, and meet the requirements of the construction environment. The effect of low construction cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

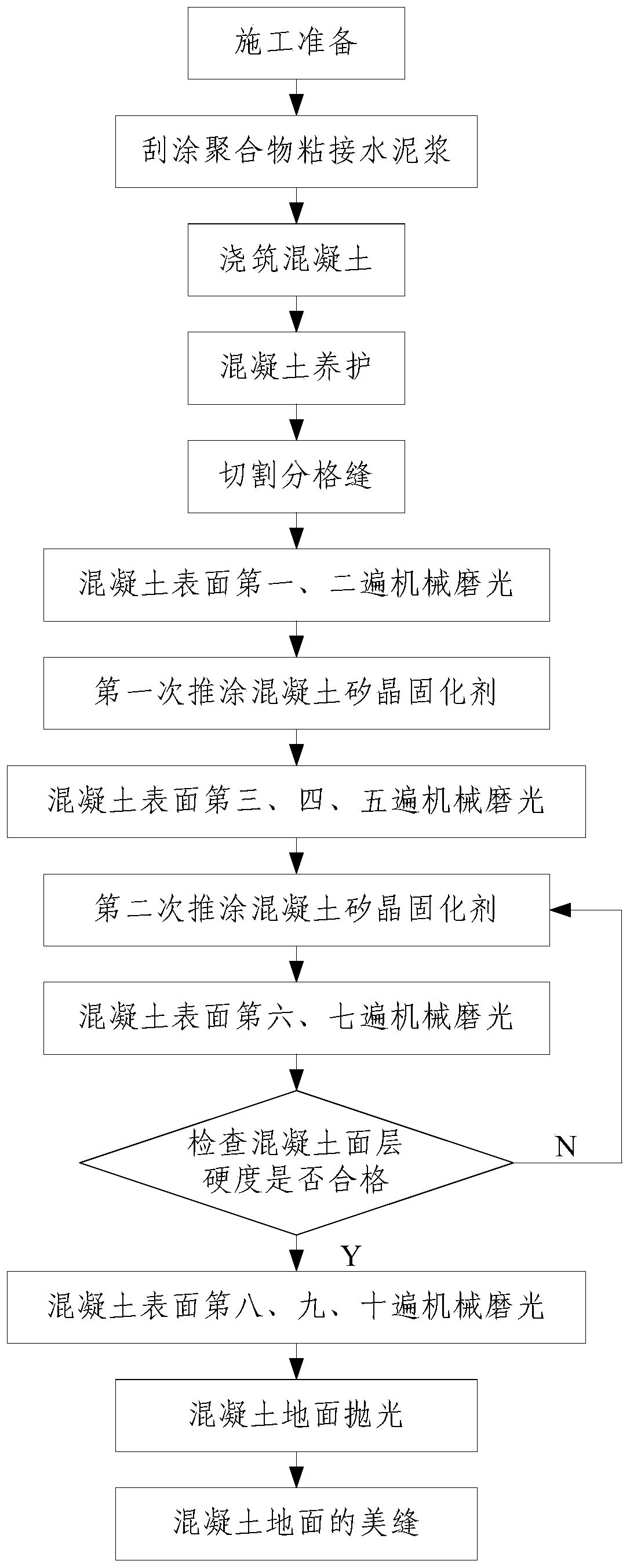

[0051] Such as figure 1 As shown, the wear-resistant concrete terrazzo ground construction method of the present invention comprises the following steps:

[0052] Step 1, construction preparation, the process is as follows:

[0053] Step 101. Use a ground roughing machine to roughen the surface of the base, and then use a floor cleaning machine, a vacuum cleaner, and a broom to clean up the soil and floating slurry on the surface of the base; if there is oil on the surface of the base, apply a mass concentration of 5% to 10% % caustic soda solution to clean the base surface with oil stains;

[0054] Step 102, playing the elevation control line on the side walls and columns of the construction site;

[0055] Step 103, retaining deformation joints at the edge of the wall column;

[0056] In this embodiment, the indwelling process of the deformation joints at the side of the wall column in step 103 is: cutting the polystyrene board into strips of polystyrene slats, the width o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Penetration depth | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com