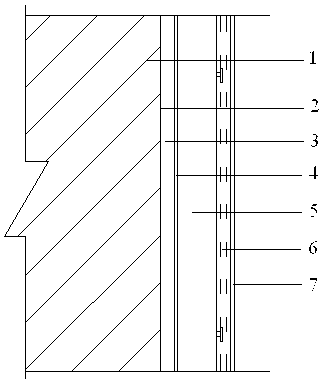

Thick plastered exterior wall outer heat-insulation system with double-layer gridding cloth compounded with foam cement boards

A technology for external thermal insulation of external walls and foamed cement boards, which is applied in the field of building thermal insulation materials, can solve the problems of large size deviation, large seams, and difficult grinding of foamed cement boards, so as to improve wind pressure resistance and enhance system safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The caulking and leveling insulation material consists of 570 parts of ordinary Portland cement, 125 parts of Class I fly ash, 320 parts of lightweight aggregate, 5 parts of methyl hydroxypropyl cellulose ether, 0.3 part of starch ether, and 10 parts of redispersible latex powder 1 part, 3 parts of fiber with a diameter of 6 mm, among which, the lightweight aggregate is made by mixing 70 mesh vitrified microspheres and floating beads according to the weight ratio of 2:1.

Embodiment 2

[0044] The caulking and leveling insulation material consists of 600 parts of Portland cement, 150 parts of Class I fly ash, 350 parts of lightweight aggregate, 6 parts of methyl hydroxypropyl cellulose ether, 0.5 part of starch ether, 20 parts of redispersible latex powder, It is made of 3 parts of fiber with a diameter of 4 mm, and the lightweight aggregate is made of 50 mesh vitrified microspheres and floating beads in a weight ratio of 2:1.

Embodiment 3

[0046] The caulking and leveling insulation material consists of 450 parts of ordinary Portland cement, 100 parts of Class I fly ash, 300 parts of lightweight aggregate, 4 parts of methyl hydroxypropyl cellulose ether, and 5 parts of redispersible latex powder, with a diameter of 8 It is made of 2 parts of mm fiber, and the lightweight aggregate is made by mixing 60 mesh vitrified microspheres and floating beads according to the weight ratio of 3:2.

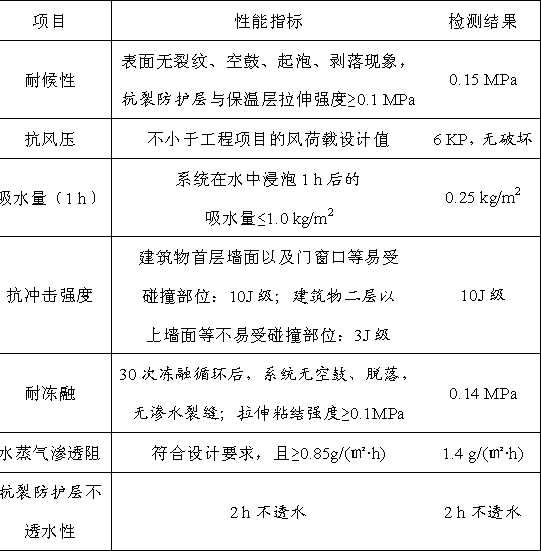

[0047] Table 1 shows the physical performance testing indexes of the gap-filling and leveling insulation materials prepared in Implementation 1-Example 3.

[0048] Table 1

[0049] project unit Example 1 Example 2 Example 3 Thermal Conductivity W / (m·k) 0.72 0.85 0.68 Compressive strength MPa 1.0 1.5 0.9 tensile strength MPa 0.15 0.15 0.15 Water absorption (V / V) % 6.0 6.0 7 Softening coefficient - 0.85 0.90 0.82

[0050] Implementation 1-Example 3 The gap-filli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com