Method for model quality statistics of on-line monitoring closed-loop control system

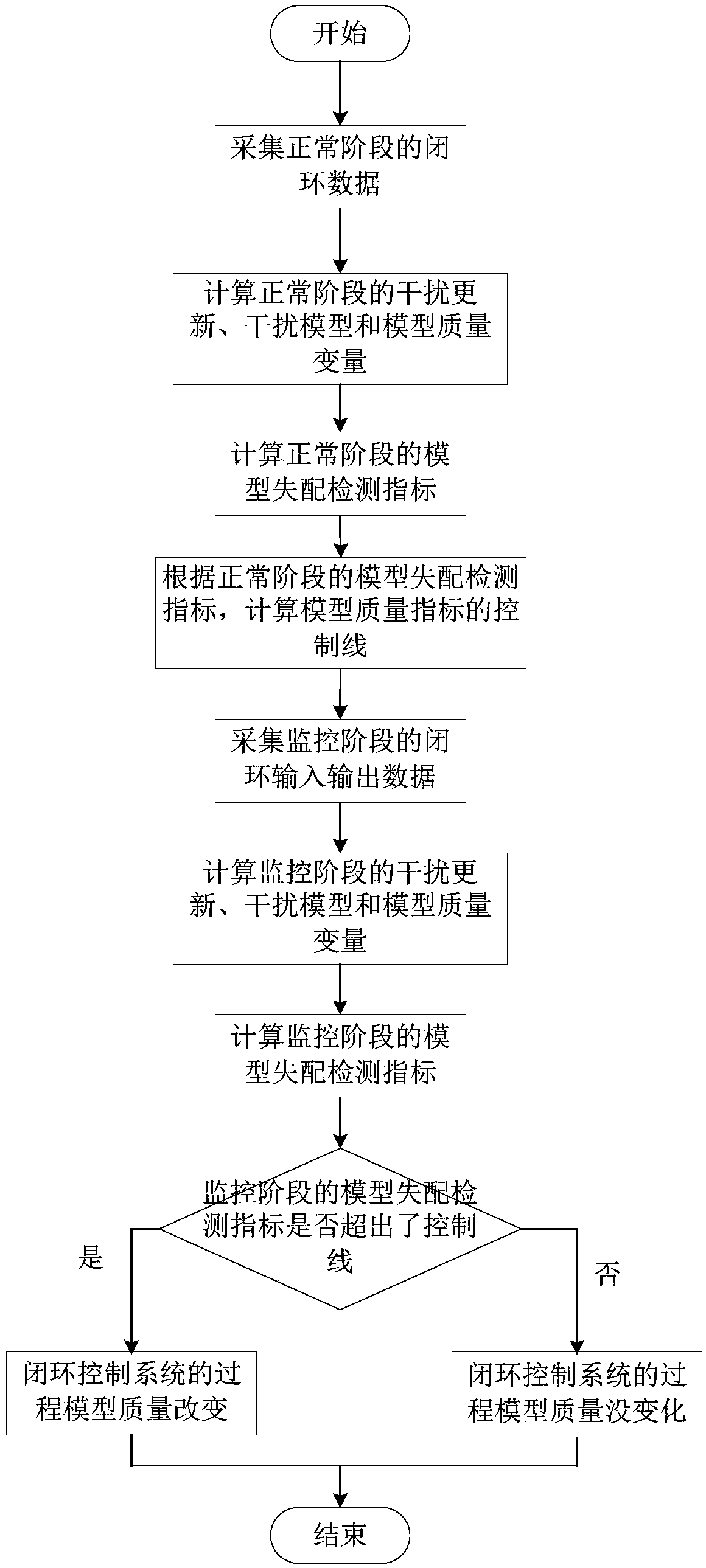

A technology of closed-loop control and system model, which is applied in general control system, control/regulation system, adaptive control, etc., and can solve problems such as inability to monitor process model mismatch in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

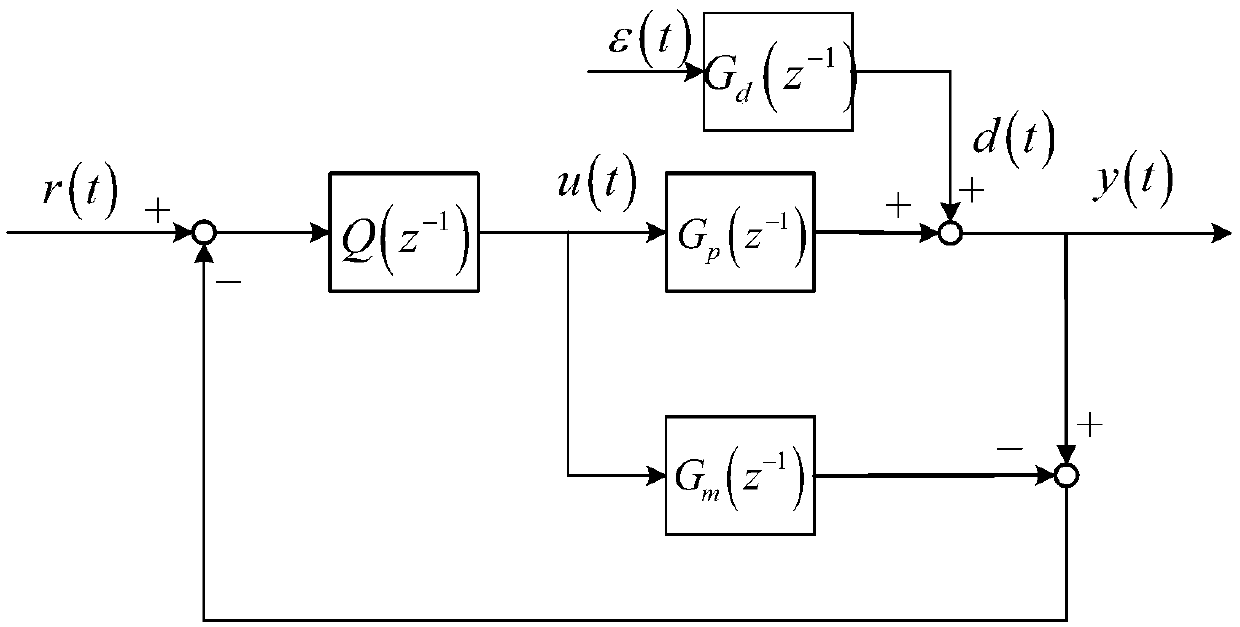

Method used

Image

Examples

Embodiment 1

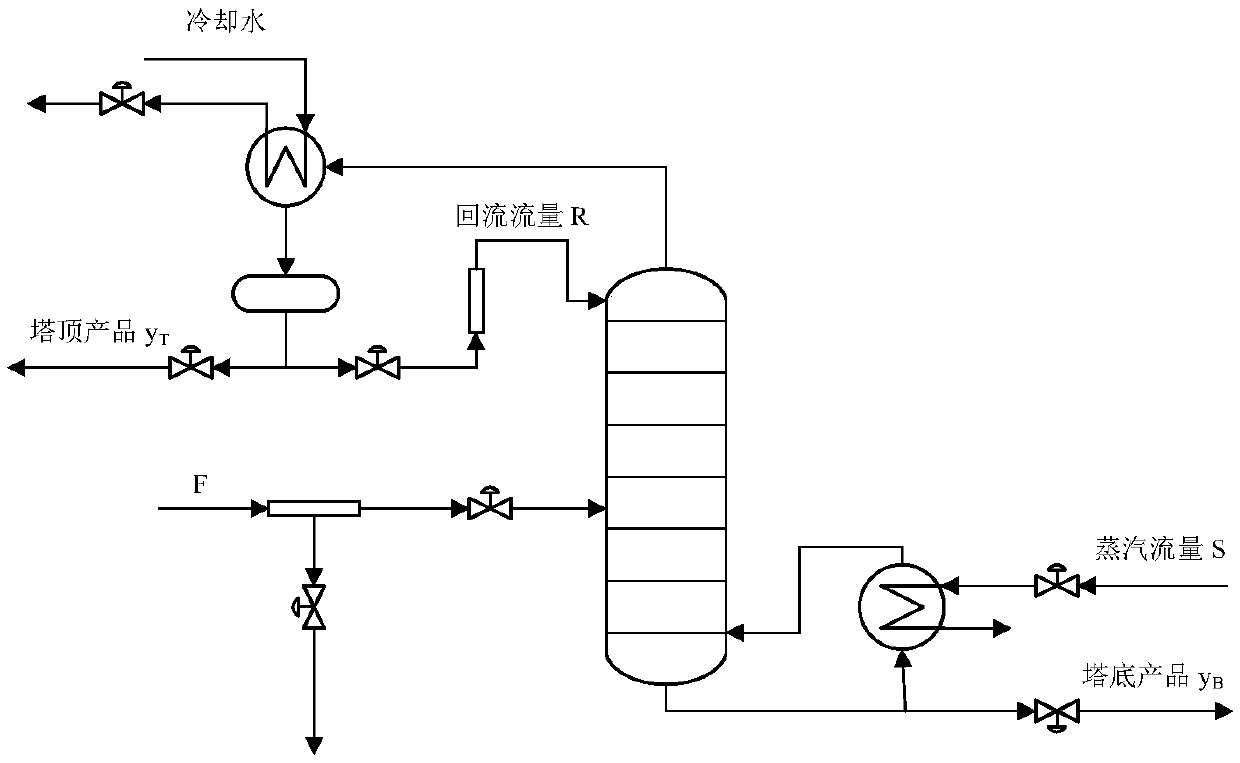

[0156] The following takes the Wood-Berry distillation column process as Example 1 to further illustrate the method for on-line monitoring of the model quality of the closed-loop control system provided by the present invention.

[0157] Wood-Berry distillation column process such as image 3 As shown, the specific process is as follows: (1) raw material D enters from the feed plate, and the feed plate divides the whole rectification tower into a rectification section and a stripping section; (2) after the solution enters the rectification tower, due to methanol It has a different boiling point from water, which causes the low boiling point components to vaporize and rise upwards, while the high boiling point components mostly flow down with the liquid, and rise on the trays with the rising steam in the rectification column Carry out sufficient contact, thereby carry out the process of heat transfer and mass transfer; (3) after the liquid flowing to the raw material F flows to...

Embodiment 2

[0177] The method for on-line monitoring of the model quality of the closed-loop control system provided by the present invention will be further described below by taking the liquid mixing process of a continuous stirring tank as Example 2.

[0178] Continuously stirred tank liquid mixing process such as Figure 14 As shown, the specific process is as follows: the unmixed liquid enters the continuous mixing tank through a pipe, and is fully mixed in the tank, and finally flows out from the outlet of the mixing tank. Among them, C in Indicates the concentration at the inlet of the pipe, C out Indicates the concentration at the outlet of the stirring tank, V p Indicates the volume of the pipe, V t Represents the volume of the continuous stirring tank, and q represents the flow rate of the liquid in the pipeline.

[0179] According to the law of conservation of mass, the liquid mixing process is described by differential equations as follows:

[0180]

[0181] Among them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com