Pre-embedding construction method for distribution box with rows of pipes, and support device

A construction method and technology for distribution boxes, applied to electrical components, buildings, building structures, etc., can solve problems such as difficult quality control of distribution boxes with rows of distribution pipes, achieve practical and reliable construction technology, and solve common quality problems , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

[0060] see Figure 1-14 , the present invention comprises the following steps:

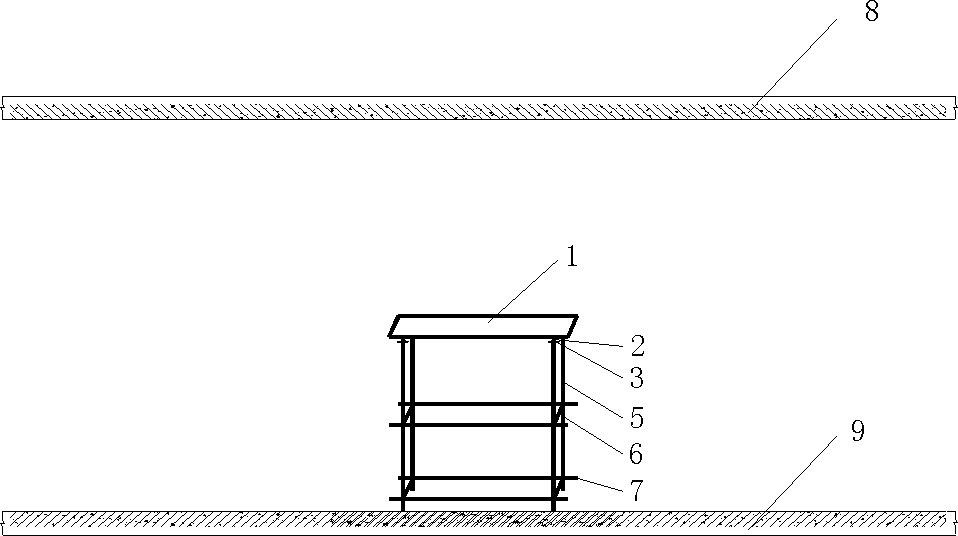

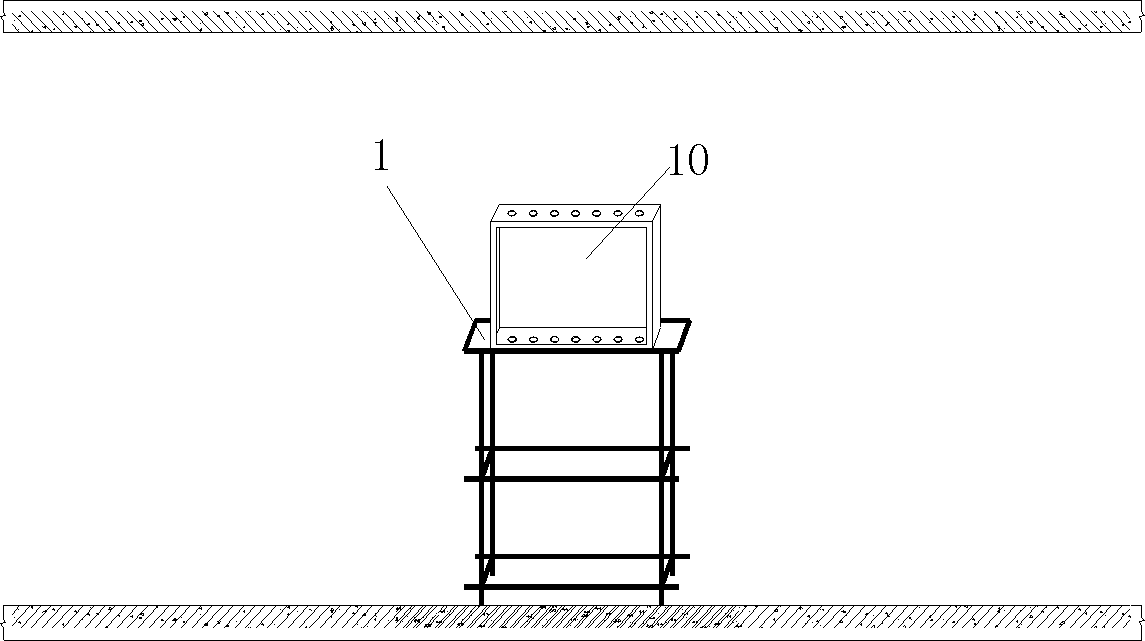

[0061] 1) First use the temporary adjustable support platform to fix the distribution box to the designed position;

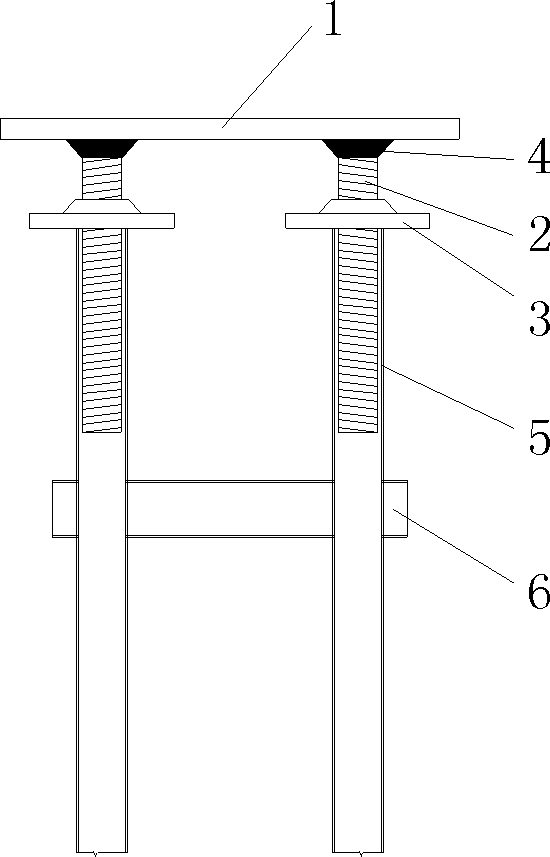

[0062] Temporary adjustable support platform assembly: eg figure 1 , figure 2 As shown, the steel plate 1 is selected, and the four bolts 2 are welded firmly through the weld seam 4 at the corresponding position below the steel plate. And 4 adjustable nuts 3 are rotated and inserted into the bolts 2. The 4 steel pipe vertical rods 5 are welded and fixed in two layers by 4 short connecting steel pipes 6 and 4 long connecting steel pipes 7 (the space size requires that 4 bolts 2 can be inserted into the inside of the 4 steel pipe vertical rods 5 respectively at the same time). Then 4 bolts 2 are inserted into 4 steel pipe vertical rods 5 insides simult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com