Support method and device of support pile preformed core-soil double-buttress inclined inner-strut foundation ditch

A technology for reserving core soil and foundation pit support, applied in excavation, foundation structure engineering, construction, etc., can solve the problems of high cost, long construction period, complex construction, etc., achieve convenient material acquisition, improve construction efficiency, and reduce earthwork excavation The effect of digging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

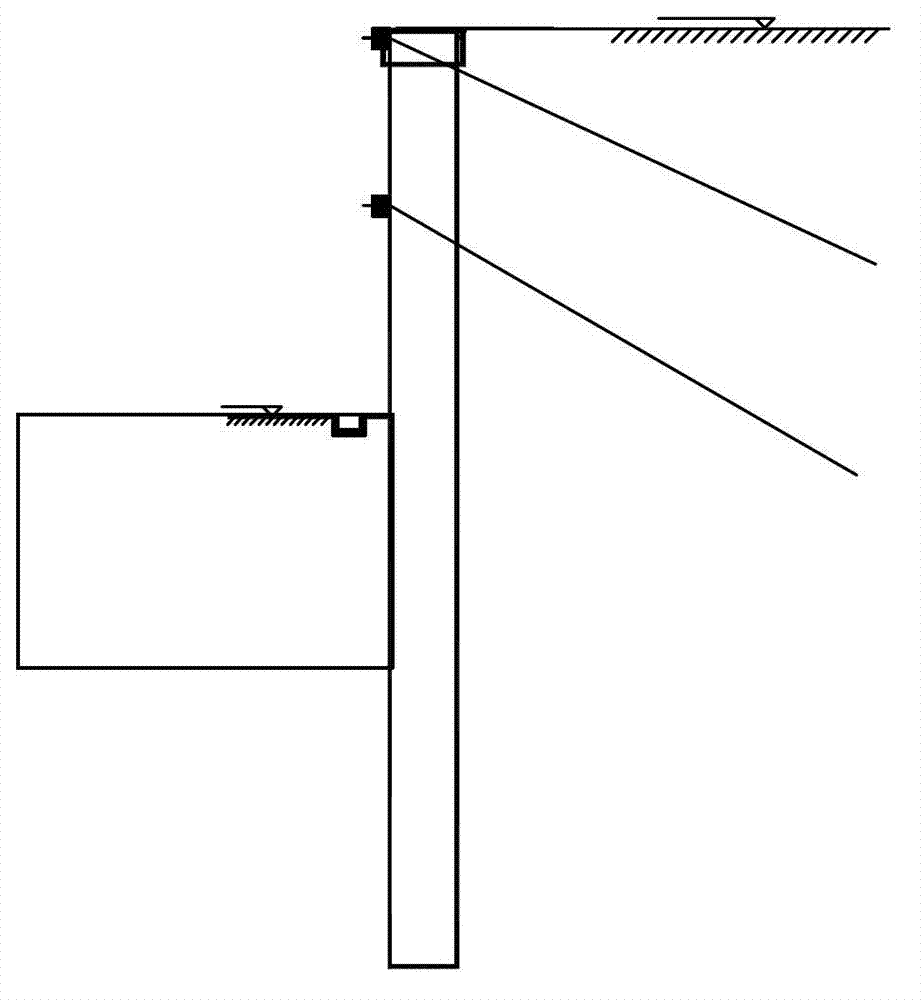

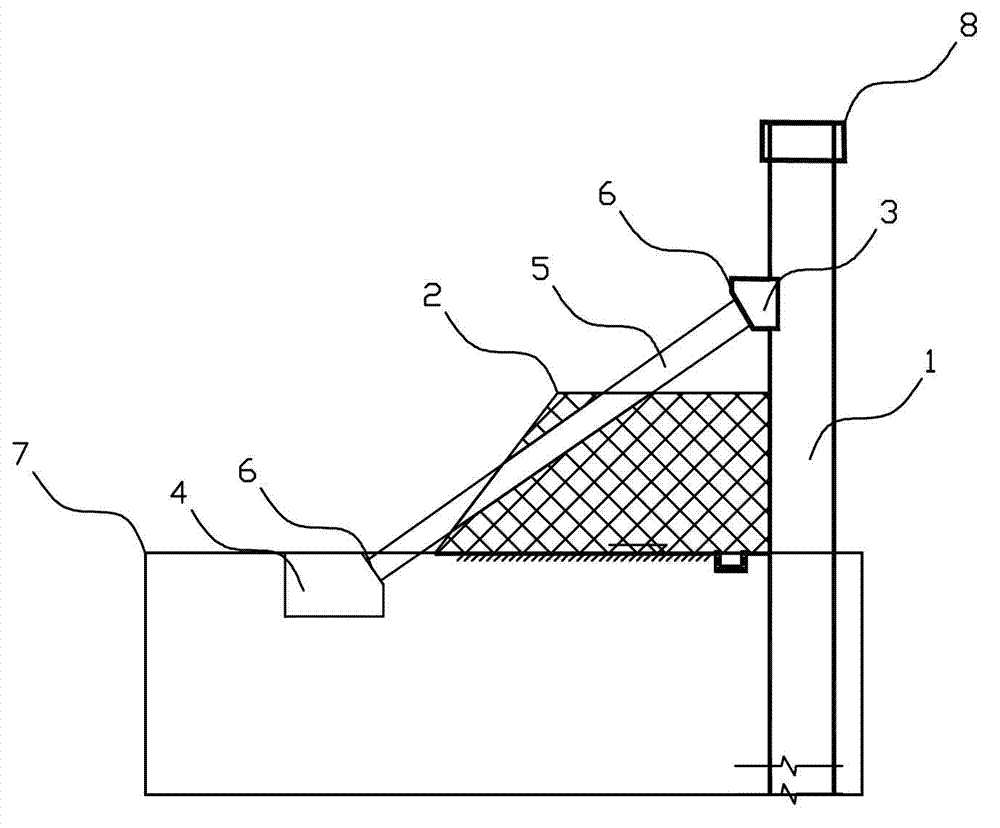

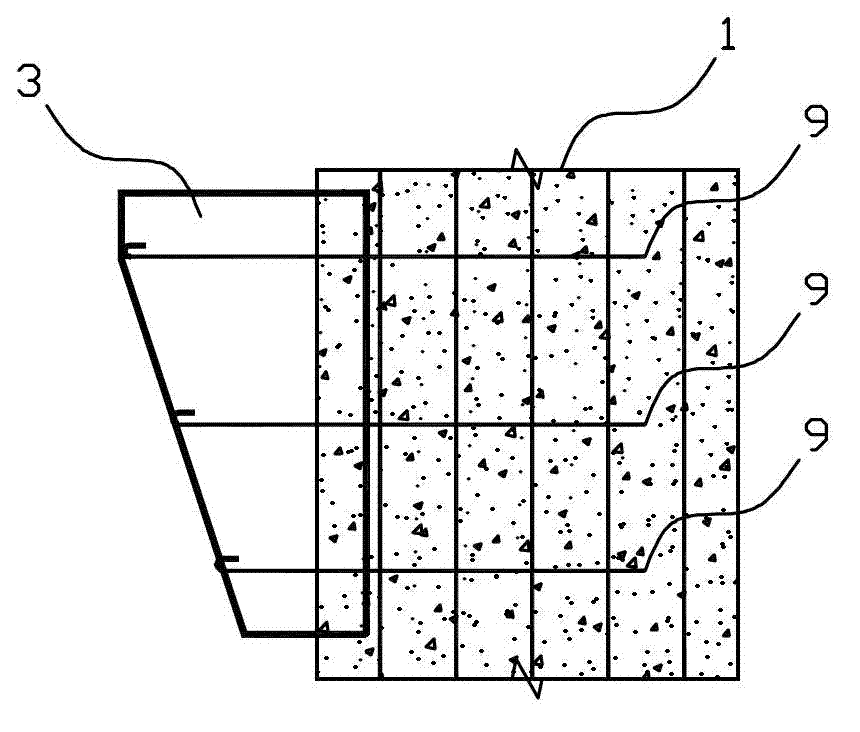

[0042] like figure 2 As shown in the figure, a foundation pit support device with double support pier with reserved core soil includes a support pile 1, and the support pile 1 and the basement floor 7 are provided with a diagonal bracing mechanism. The core soil is reserved near the support pile 1. The diagonal bracing mechanism is as follows: a pile body buttress 3 is buried in the support pile 1 body, a bottom plate buttress 4 is buried in the basement floor 7, and a diagonal brace beam 5 is diagonally braced between the pile body buttress 3 and the bottom plate buttress 4.

[0043] The support pile 1 is a support body that resists the load outside the foundation pit. The strength of the support pile 1 must meet the requirements for supporting the load of the foundation pit. It can be a reinforced concrete structure or a steel structure, using traditional cast-in-place piles or steel piles as support Structural retaining body.

[0044] Core soil 2 is the undisturbed soil ...

Embodiment 2

[0051]This embodiment is an implementation with caps. Preferably, the diagonal brace angle of the section steel is in the range of 50°-55° to meet the requirements. In this embodiment, the diagonal brace angle is 50°.

[0052] In actual construction, the complete steps are as follows:

[0053] The first step: construction of support pile 1

[0054] The second step: crown beam 8 construction

[0055] Step 3: Excavate the earth layer by layer to the pier 3 of the pile body, and carry out the construction of the pier 3 of the pile body;

[0056] Step 4: Excavate the earth in layers and sections, and leave the core soil 2;

[0057] Step 5: Pour and tamp construction of floor support pier 4;

[0058] Step 6: The diagonal brace beam 5 is hoisted in place and welded firmly with the steel plate 6 of the pile body support pier 3 and the bottom plate support pier 4;

[0059] Step 7: Construction of basement floor 7 and shear wall, backfilling of earthwork and pouring and tamping of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com