Construction joint waterproof construction method for combined design of water stop steel plate and anti-crack steel bars

A water-stop steel plate and construction method technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as difficult maintenance, difficult repair, rubber water-stop damage, etc., to reduce maintenance costs in the later period, The effect of reducing the maintenance probability and increasing the flow path of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

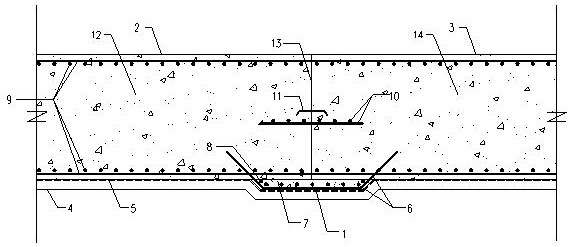

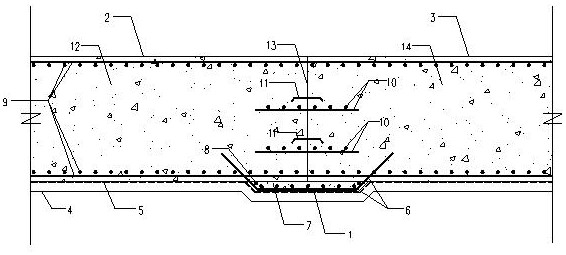

Embodiment 1

[0052] The construction method of the construction joint waterproof structure of the basement floor waterproof steel plate and the anti-crack steel bar combination design of the embodiment of the present invention:

[0053]The first step is to dig the foundation floor pit to the design elevation and compact it, and then dig 10cm down within the range of 500mm on the left and right sides of the construction joint to form an oblique trench and compact it;

[0054] The second step is to construct a 100mm thick C15 concrete cushion;

[0055] The third step is to lay the pre-laid anti-adhesive waterproof membrane, and lay the membrane according to the shape of the repair within 500mm from the left and right of the construction joint position;

[0056] The fourth step is to bind the Φ8@50 anti-cracking steel mesh in the 10cm deep oblique groove, and leave a steel bar not less than the anchoring length at each of its longitudinal ends to be anchored in the floor;

[0057] The fifth ...

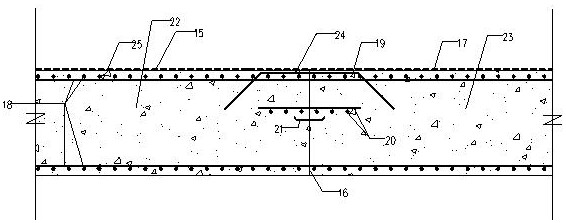

Embodiment 2

[0065] image 3 It is a schematic diagram of a waterproof structure of a vertical construction joint combined with a basement floor waterproof steel plate and crack-resistant steel bars according to an embodiment of the present invention. The construction method of the combined vertical construction joint of the basement wall "crack-resistant steel bar + water-proof steel plate" of the present invention:

[0066] The first step is to bind the steel bars on the left side of the construction joint;

[0067] The second step is to bind the additional anti-cracking reinforcement Φ8@50 on the outside of the external wall at the construction joint, and extend the anti-cracking reinforcement into the wall reinforcement cage on both sides of the construction joint, and its length is not less than the anchorage length of the anti-cracking reinforcement;

[0068] The third step is to install a 4mm thick steel plate waterstop in the middle of the wall;

[0069] The fourth step is to ins...

Embodiment 3

[0076] Figure 4 It is a schematic diagram of the waterproof structure of the combined horizontal construction joint of the basement floor waterproof steel plate and anti-crack steel bar according to the embodiment of the present invention. The construction method of the basement wall "crack-resistant steel bar + water-stop steel plate" combined horizontal construction joint of the present invention:

[0077] The first step is to construct the waterproof layer of the bottom plate;

[0078] The second step is to construct the bottom plate reinforcement, exterior wall reinforcement, outer crack-resistant reinforcement at the construction joints of the outer wall, middle crack-resistant reinforcement, 4mm thick steel plate waterstop, and the lengths of the outer crack-resistant reinforcement and the middle crack-resistant reinforcement to be the same as those on both sides of the construction joint. Meet the anchorage length;

[0079] The third step is to install the template; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com