Underground continuous wall support replacement structure and construction method

A technology for underground diaphragm walls and construction methods, applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of low reuse rate, consumption of consumables and labor, unfavorable demolition of underground diaphragm walls 11a, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

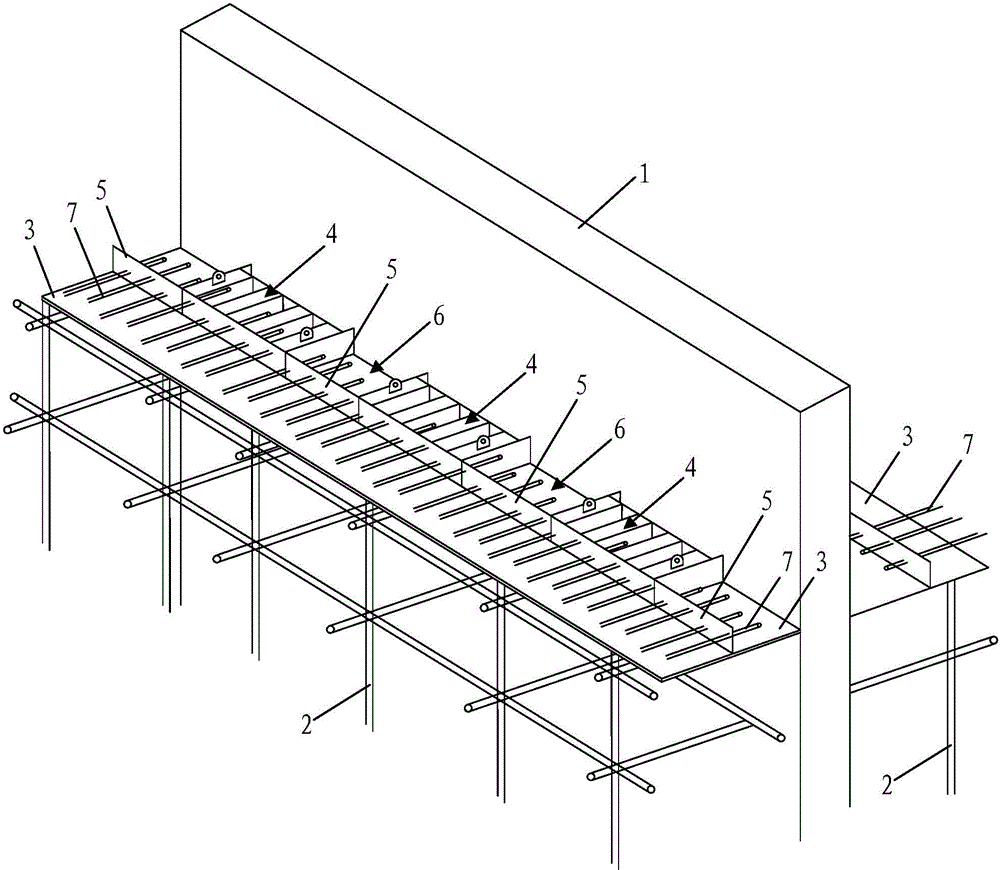

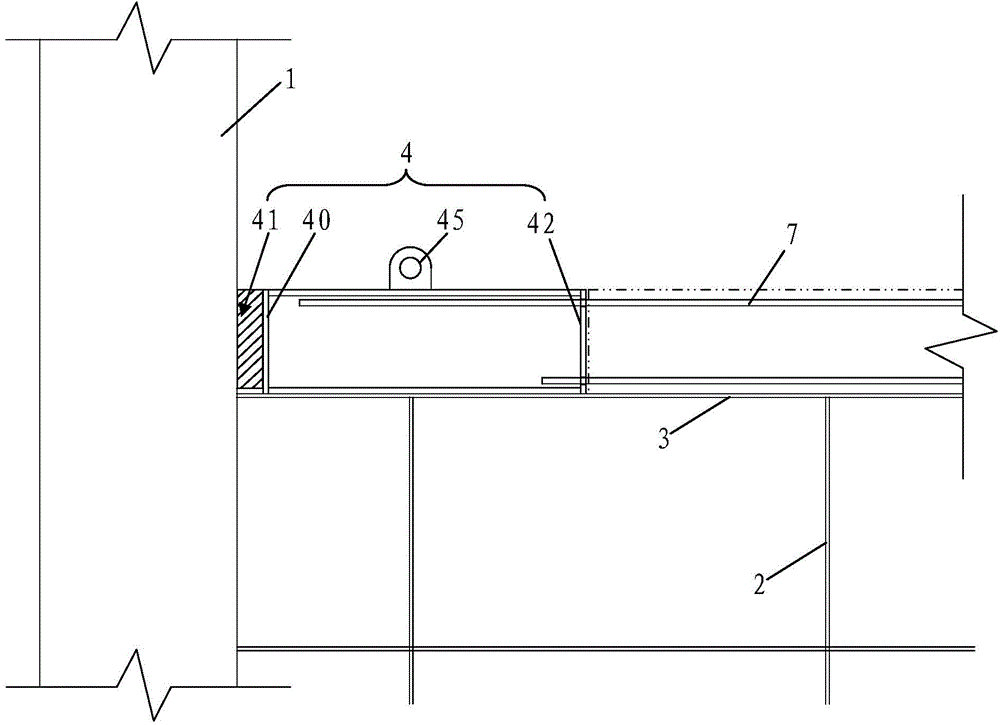

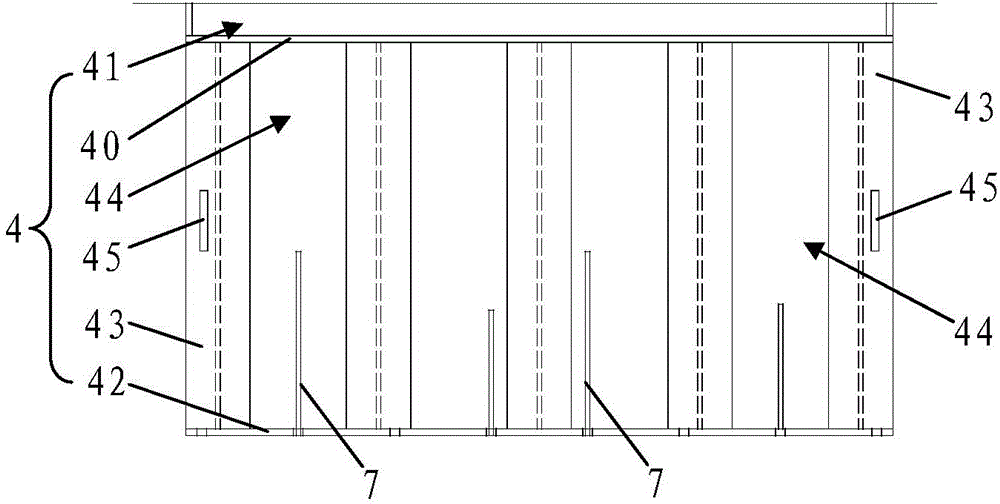

[0044] refer to figure 1 , is a schematic diagram of the three-dimensional structure of the first embodiment of the continuous wall support structure of the present invention. Such as figure 1 As shown, the present invention firstly provides a diaphragm wall replacement structure for pouring on both sides of the underground diaphragm wall 1 to form a basement floor, and facilitates butt jointing of the floor steel bars 7 extending out of the basement floor. The brace replacement structure includes a brace replacement unit erected between the underground diaphragm wall 1 and the pouring area of the floor slab. The brace replacement unit includes: a vertical support 2 erected along the length direction of the underground diaphragm wall 1; a formwork 3 laid horizontally on On the bracket 2 and close to the wall surface of the underground diaphragm wall 1, the floor pouring area is formed on the formwork; a plurality of supporting bodies 4 are respectively arranged horizontal...

Embodiment 2

[0058] refer to Figure 9 , is a schematic diagram of the side structure of the second embodiment of the continuous wall brace structure of the present invention. refer to Figure 10 , for the corresponding Figure 9 Schematic diagram of the top view structure. combine Figure 9 and Figure 10 As shown, on the basis of Embodiment 1, a lying stiffening beam 46 is fixed between the first side plate 40 and the plurality of support beams 43, and between the second side plate 42 and the plurality of support beams 43. The stiffening beam 46 is an I-beam and is arranged along the length direction of the underground diaphragm wall 1. The upper and lower two stiffening beams 46 are stacked on top of each other. In this way, the structural strength of the supporting body 4 itself is increased.

[0059] The implementation process is also based on the first embodiment, after the floor steel bar 7 passes through the second side plate 42, it further passes through the stiffening beam ...

Embodiment 3

[0061] refer to Figure 11 , is a schematic diagram of the side structure of the third embodiment of the continuous wall brace structure of the present invention. refer to Figure 12 , for the corresponding Figure 11 Schematic diagram of the top view structure. combine Figure 11 and Figure 12 As shown, on the basis of Embodiment 2, a plurality of stiffening plates 47 are fixed and tightened between the flanges of the stiffening beams 46, and the stiffening plates 47 are perpendicular to the wall surface of the underground diaphragm wall 1 to further strengthen the supporting body. 4 Its own structural strength can withstand greater pouring extrusion force.

[0062] The implementation process is basically the same as the implementation process of the second embodiment, so it will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com