Bidirectional ventilation and pneumatic pile-turning composting process

A composting method and air pressure technology, applied in organic fertilizers, fertilization devices, climate change adaptation, etc., can solve the problems of void ratio loss, pile overturning, odor and aerosol pollution, etc., to reduce volume demand and increase speed , the effect of slowing down the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

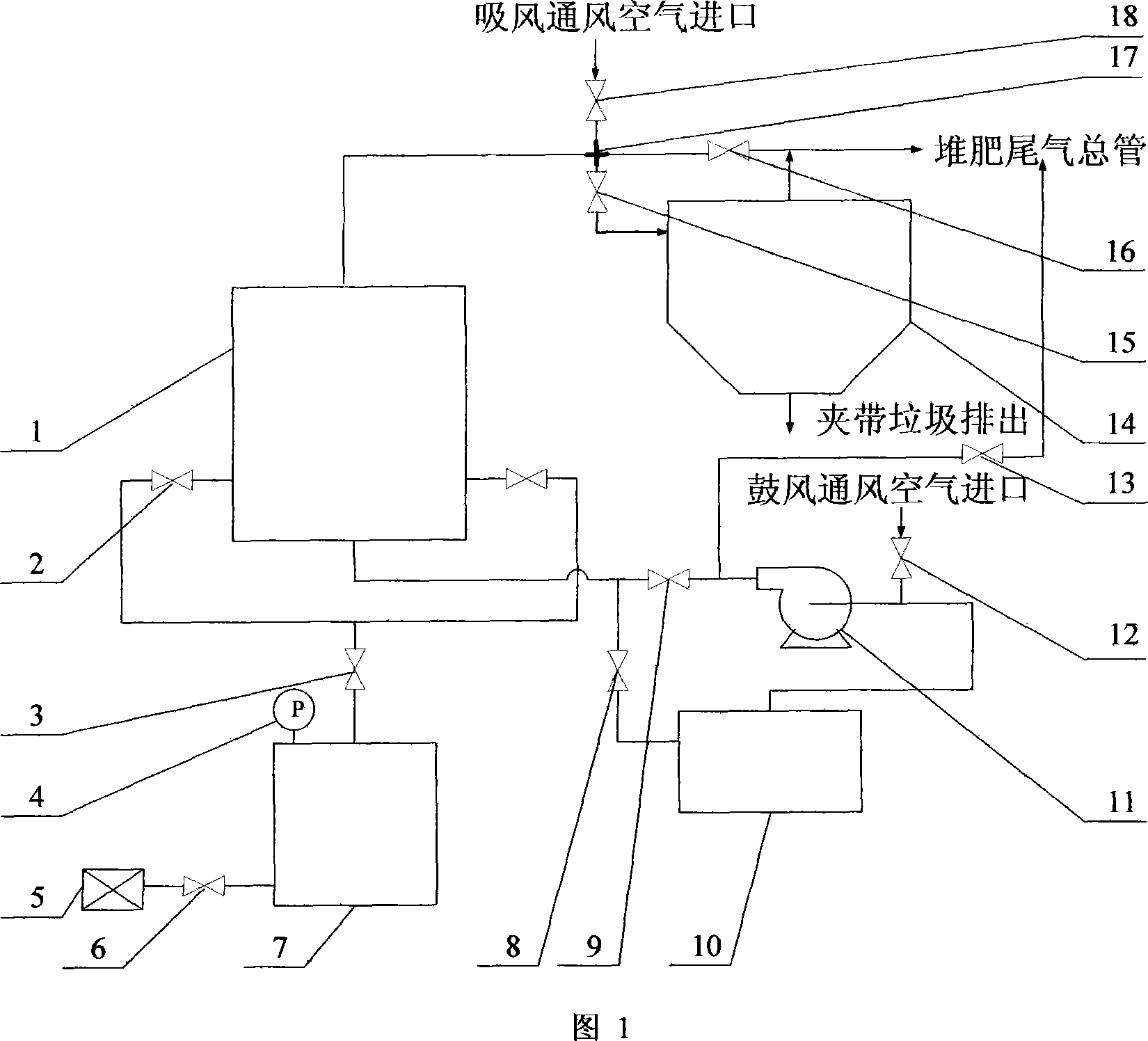

[0021] Please refer to Fig. 1 and 2, the specific embodiment of the present invention is as follows.

[0022] Treatment object: 100t / d of dewatered sludge from sewage treatment plant, moisture content 80%, before composting, adjust the moisture content of the mixture to 60% according to the conventional requirements of the composting process, mix it with broken straw in a weight ratio of 1∶0.4 Mixing, so that the moisture content of the mixture is adjusted to 60%, the actual composting material volume is 140t / d, and the material bulk density is 0.6t / m 3 .

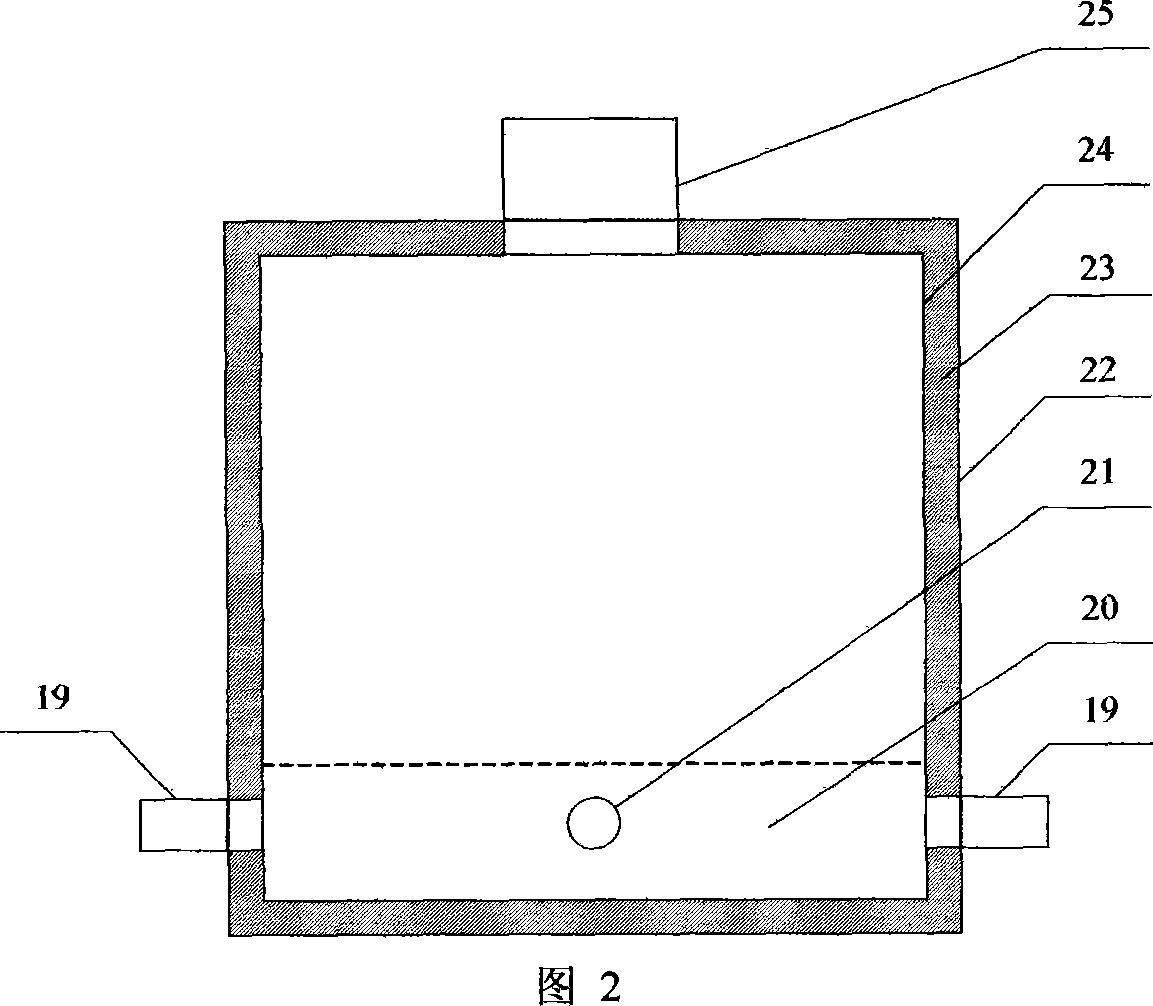

[0023] Main processing equipment: box-type composting reactor 1 is a container-type structure. According to the requirements of the amount of materials handled per day above, the calculated stacking volume is 233m 3 , the stacking height is 2.33m, and the reactor width is 5m, so the reactor length is 20m, and a 0.87m high buffer space is left above the material stack. A gas distribution layer 20 with a height of 0.3m is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com