Thrum finding device of automatic winding CBF thrum picker

A technology of automatic winding and automatic winding machine, which is used in transportation and packaging, transportation of filamentous materials, and thin material processing, etc., can solve the problem of frequent repeated search of equipment, increased wear and tear of equipment parts, and high labor intensity of employees. and other problems, to achieve the effect of improving the success rate of finding a head, saving repair costs, and reducing labor intensity

Inactive Publication Date: 2014-08-27

SHANDONG WEIQIAO PIONEERING GROUP

View PDF5 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In actual production, it is difficult for the automatic winding machine to find the ends of high-count yarns and small yarns. Hidden quality problems such as yarn scraping and feathering, as well as increased wear and tear on equipment and parts, increased repair costs, which also brought a lot of burden to the enterprise

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

[0021] The above descriptions are not intended to limit the present invention, and the present invention is not limited to the above-mentioned examples. Changes, modifications, additions or substitutions made by those of ordinary skill in the art within the scope of the present invention shall also belong to the present invention scope of protection.

specific Embodiment approach 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

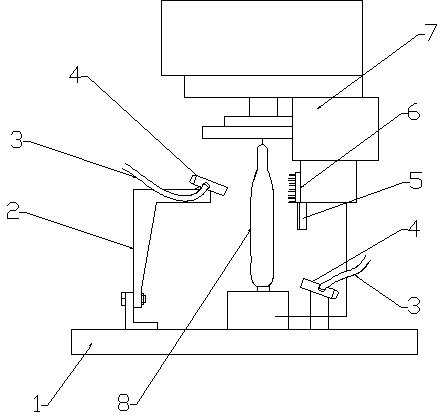

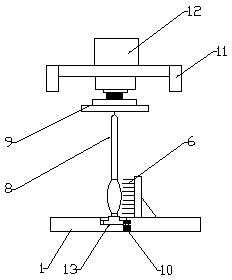

The invention relates to spinning equipment in the textile filed, in particular to a thrum finding device of an automatic winding CBF thrum picker. The device comprises an automatic winding machine. A yarn thrum lifting device and a smoothing brush are arranged below the thrum picker. When regular cop is on the winding machine, the yarn thrum lifting device comprises a right-angled support installed at the position of the thrum picker, one end of the right-angled support is fixed under the CBF thrum picker, and the other end of the right-angled support is provided with a compressed air blowing nozzle. A brush used for smoothing yarn is additionally arranged above a scraper of the thrum picker, and a blowing nozzle is additionally arranged below the brush. According to the thrum finding device of the automatic winding CBF thrum picker, the frequency of small yarn treatment can be reduced greatly for a tender, the labor intensity of the tender is relieved, abrasion of parts of equipment is reduced, repairing cost is reduced, and consumption is reduced.

Description

technical field [0001] The invention relates to spinning equipment in weaving, in particular to an automatic winding CBF head picking device. Background technique [0002] The bobbin feeding device in the automatic winding machine equipment includes a yarn storehouse, a spinning device (head finding, spinning) and a tube arrangement device. One of the fully automatic head-forming devices is referred to as CBF, which is used for fine-bonding. In actual production, it is difficult for the automatic winding machine to find the ends of high-count yarns and small yarns. Hidden dangers in quality such as yarn scraping and feathering, as well as increased wear and tear on equipment and parts, increased repair costs, which also brought a lot of burden to the enterprise. Contents of the invention [0003] The purpose of the present invention is to solve the problems existing in the prior art, and design an automatic winding CBF head picking device, the detection speed is fast, th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65H67/08

Inventor 李波

Owner SHANDONG WEIQIAO PIONEERING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com