Heat treatment process for improving low-temperature impact work of 42CrMo bearing

A low-temperature impact, quenching and tempering heat treatment technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as uneven performance, reduced comprehensive mechanical properties of steel, and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention is described below in conjunction with accompanying drawing and specific embodiment:

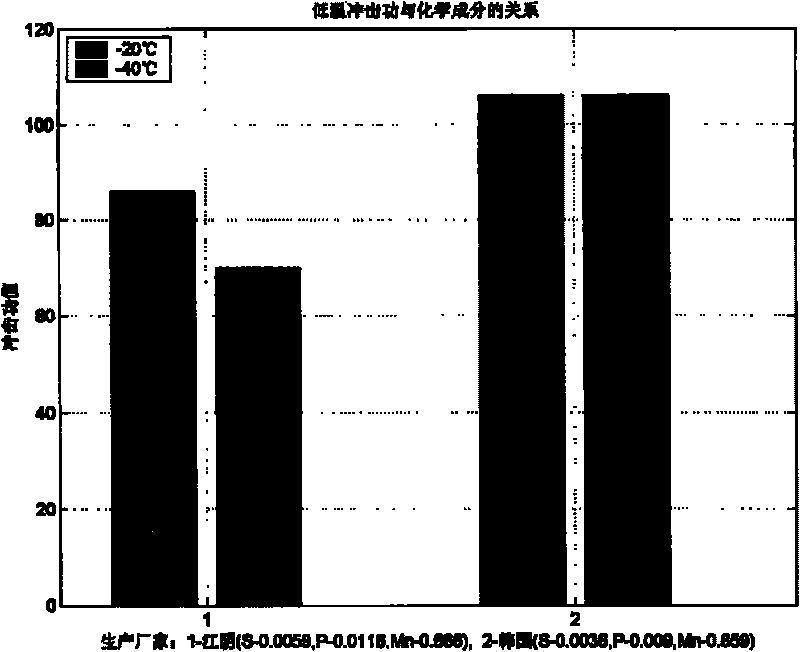

[0074] When formulating the quenching and tempering heat treatment process for wind power bearing forgings, the present invention comprehensively considers the factors affecting its low-temperature impact energy such as material, quenching medium, grain size, metallographic structure, quenching temperature and tempering temperature, and formulates a formula that can significantly improve The heat treatment process of its low-temperature impact energy, its quenching and tempering process parameters are as follows:

[0075] Quenching and tempering heat treatment quenching heating temperature: 840℃±10℃;

[0076] Quenching and tempering heat treatment quenching holding time (h): 3.5 hours;

[0077] Quenching and tempering heat treatment tempering heating temperature: 580°C±10°C;

[0078] Quenching and tempering heat treatment tempering holding time (h): 8 hours;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com