Steel plate for cryogenic container and production method thereof

A production method and low-temperature container technology, applied in the field of steel plates for low-temperature containers, can solve problems such as high cost and poor Z-direction performance, and achieve the effects of high low-temperature impact energy, excellent comprehensive performance, and high tensile area reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This example is: 10mm thick steel plate for low-temperature pressure vessel and its production method. The steel plate is smelted from the following components by weight percentage: C: 0.10%, Si: 0.30%, Mn: 1.47%, Ni: 0.38%, P: 0.008%, S: 0.001%, Al: 0.040%, Nb: 0.019%, and the balance is iron and unavoidable impurities.

[0052] The steps of the steel plate production method of the present embodiment are as follows:

[0053] 1) Smelting: The molten steel containing the above weight percentage components is first smelted in an electric furnace, sent to an LF refining furnace for refining, and 17kg / t of lime is added to the steel, fed to an Al line of 700 meters to remove oxygen in the molten steel, and the white slag is kept for 35 minutes. When the temperature of the molten steel reaches 1640°C, it is transferred to the VD furnace for vacuum degassing treatment. The vacuum degree is not greater than 66.6Pa, and the vacuum holding time is 22 minutes. Before vacuuming, 1...

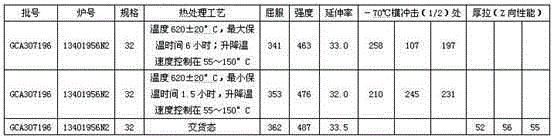

Embodiment 2

[0061] This example is: 32mm thick steel plate for low temperature pressure vessel and its production method. The steel plate is smelted from the following components by weight percentage: C: 0.11%, Si: 0.28%, Mn: 1.43%, Ni: 0.33%, P: 0.003%, S: 0.001%, Al: 0.035%, Nb: 0.017%, and the balance is iron and unavoidable impurities.

[0062] The steps of the steel plate production method of the present embodiment are as follows:

[0063] 1) Smelting: The molten steel containing the above weight percentage components is first smelted in an electric furnace, sent to an LF refining furnace for refining, and 19kg / t of lime is added to the steel, fed to an Al line of 750 meters to remove oxygen in the molten steel, and the white slag is kept for 45 minutes. When the temperature of the molten steel reaches 1635°C, it is transferred to the VD furnace for vacuum degassing treatment. The vacuum degree is not greater than 66.6Pa, and the vacuum holding time is 21 minutes. Before vacuuming, 1...

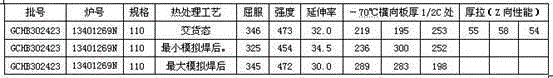

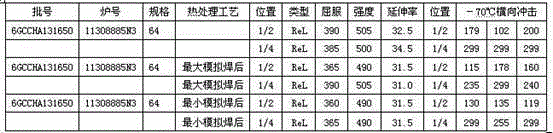

Embodiment 3

[0071] This example is: 64mm thick steel plate for low-temperature pressure vessel and its production method. The steel plate is smelted from the following components by weight percentage: C: 0.08%, Si: 0.33%, Mn: 1.46%, Ni: 0.67%, P: 0.009%, S: 0.002%, Al: 0.035%, Nb: 0.03%, and the balance is iron and unavoidable impurities.

[0072] The steps of the steel plate production method of the present embodiment are as follows:

[0073] 1) Smelting: The molten steel containing the above weight percentage components is smelted in an electric furnace first, sent to an LF refining furnace for refining, fed with lime 21kg / t steel, and the Al line is 720 meters to remove oxygen in the molten steel, and the white slag is kept for 40 minutes. When the temperature reaches 1645°C, it is transferred to a VD furnace for vacuum degassing treatment. The vacuum degree is not greater than 66.6Pa, and the vacuum holding time is 22 minutes. Before vacuuming, 165kg of CaSi block is added;

[0074] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com