Flame straightening method of bogie frame of high speed train

A high-speed EMU and flame rectification technology, which is applied in the direction of heat treatment process control, furnace and furnace type, etc., can solve the problems of inaccurate process, large randomness, and unscientific control, so as to suppress precipitation, improve measurement accuracy, and improve The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

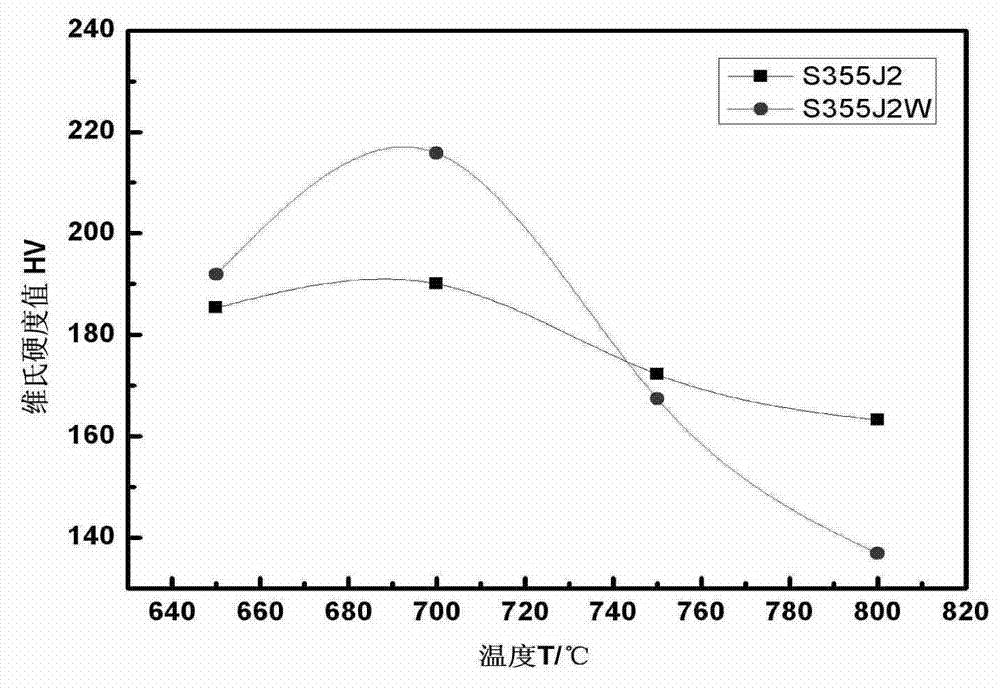

[0020] Such as figure 1 As shown, the imported high weathering steel S355J2W is much more sensitive to the flame heating temperature than the ordinary low carbon steel S355J2. When the maximum heating temperature is 800℃, the hardness of the base metal in the flame correction zone decreases by 43%. Once the flame heating temperature is improperly selected or controlled by flame straightening, the properties of the base metal in the flame heating zone will be deteriorated, and the performance and safety of the bogie frame will be seriously reduced.

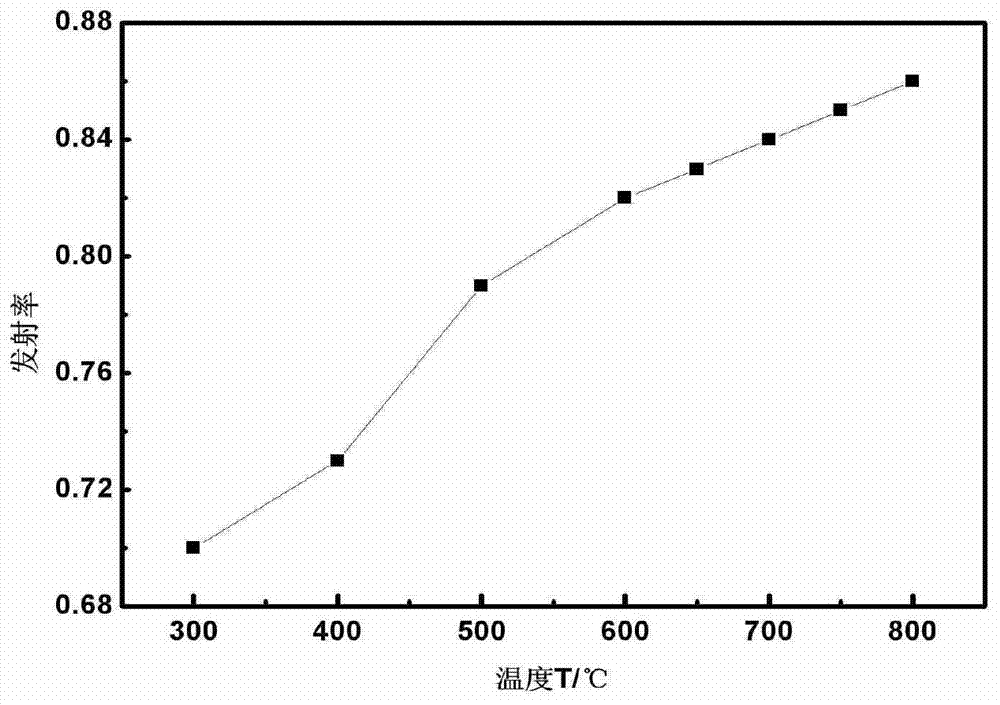

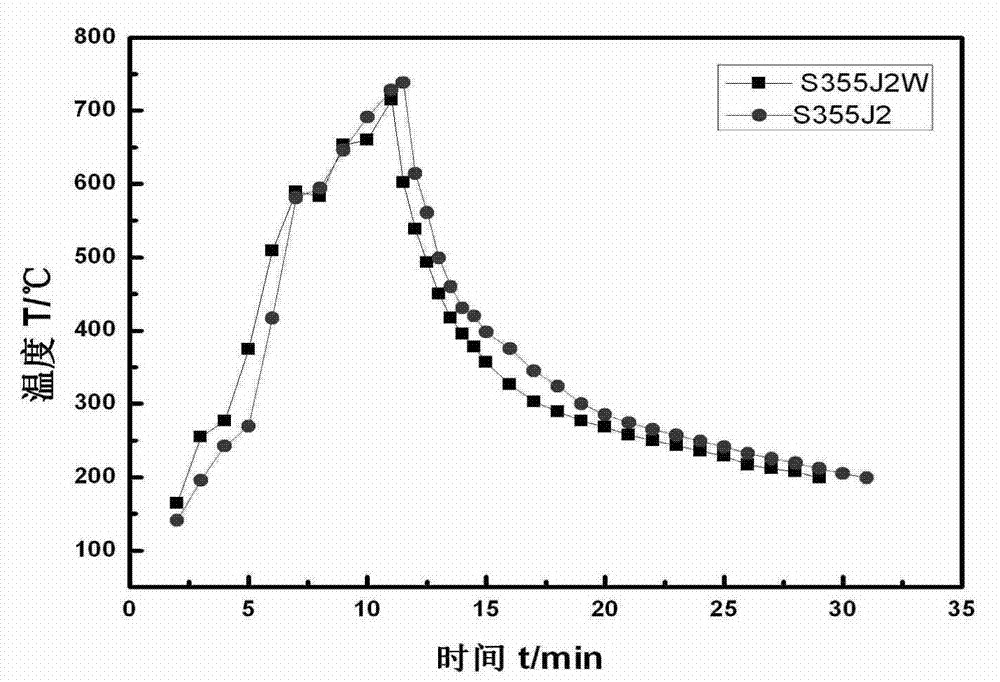

[0021] The calibration and selection of the infrared thermometer for the optimal flame heating specification parameters and cooling methods in the flame correction area of weathering steel are as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com