Welding wire and method for welding fire-resistant steel with yield strength of 420MPa grade through welding wire

A yield strength and welding wire technology, applied in the field of gas shielded welding wire and its welding, can solve problems such as increasing material cost, and achieve the effects of low production cost, excellent comprehensive mechanical properties, high and low temperature impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

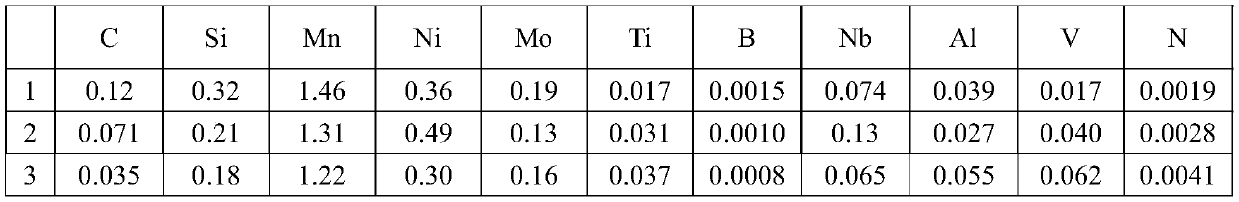

[0022] Examples are provided below to further describe the present invention in detail. The welding wire is prepared under the existing equipment and technical conditions. The welding plate is Q420FRE with a thickness of 40mm; the welding groove size, sampling position and test method are all in accordance with the national standard GB / T 12470.

[0023] The chemical composition of welding wire is listed in Table 1:

[0024] Table 1 Welding wire chemical composition mass percentage (wt.%) balance Fe and impurities

[0025]

[0026]

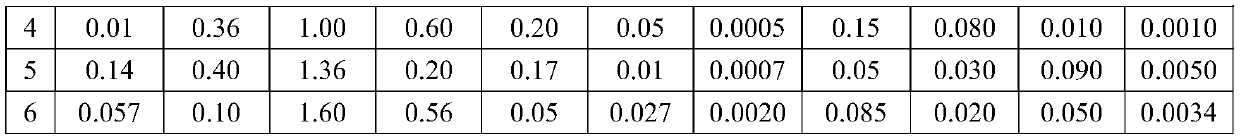

[0027] The experimental results are listed in Table 2 and Table 3.

[0028] Table 2 Mechanical properties of deposited metal

[0029]

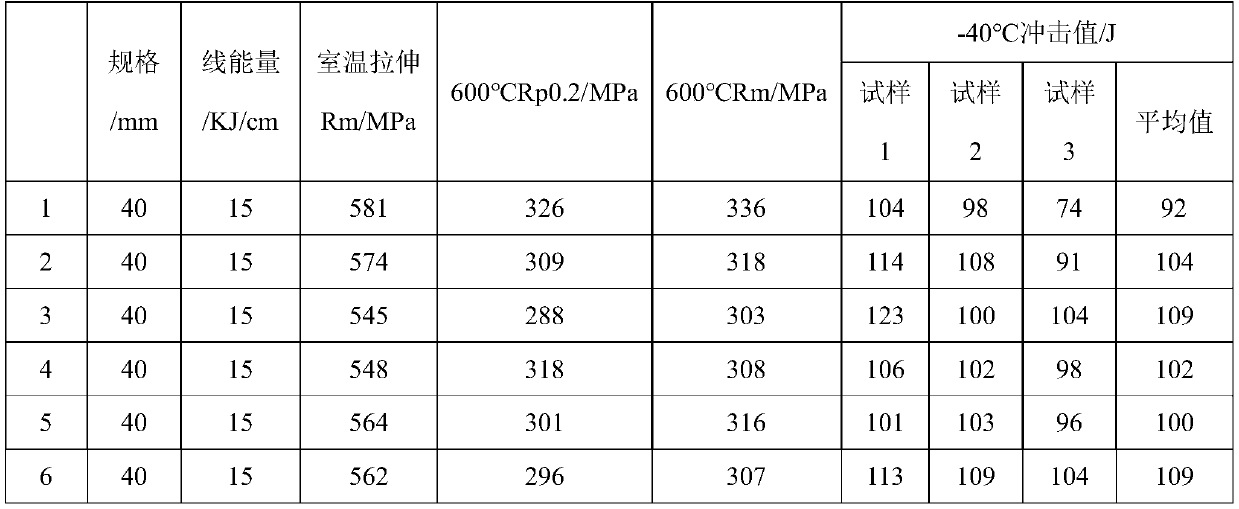

[0030] Table 3 Mechanical properties of welded joints

[0031]

[0032] It can be seen that by using the welding wire of the present invention to weld refractory steel with a yield strength of 420 MPa, the formed deposited metal and welded joints have excellent comprehensive mechanical properties, hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com